Melcher W Series 125, 250 Watt AC-DC and DC-DC DIN-Rail Converters Convert Select LWN2660-6E-G

Features

• RoHS lead-free-solder and lead-solder-exempted products are available

• Rugged 35 mm DIN-rail snap-fit design

• Class I equipment

• Universal AC-input or DC-input (66 – 150 or 90 – 350 VDC) with single stage conversion

• Power factor correction, harmonics IEC/EN 61000-3-2

• Virtually no inrush current

• Compliant with EMC standards EN IEC 61204-3, EN 50121-3-2

• Emissions according to EN 55011 / 55032

• Very high efficiency; up to 89%

• Short-term output peak power capability, rectangular current limiting characteristic

• Single or two independently regulated outputs with 12, 24, 36, or 48 V

• Outputs no-load, overload, and short-circuit proof

• PCBs coated by protective lacquer

• Very high reliability

Description

The MELCHER Convert Select series represents a family of DIN-rail mountable DC-DC and AC-DC converters with power factor

correction. The converters have been designed according to the latest industry requirements and standards.

The converters are ideal for use in outdoor and other demanding applications to power building control systems, factory automation,

industrial controls, instrumentation, electromagnetic drives, fans, and other DC loads.

Different models are available with a single output or two independently regulated, electrically isolated outputs with 12, 24, 36, or 48 V.

Special models for battery charging are available. The EW models are particularly suitable for 110 V railway applications; they have

been designed in accordance with the railway standards EN 50155 and EN 50121.

Key features of the Convert Select line include power factor correction with low harmonic distortion, negligibly low inrush current, high

immunity to transients and surges, and low electromagnetic emissions. Internal protection circuits such as input over- and undervoltage

lockout, thermal protection, as well as output overvoltage protection by a second control loop ensure safe operation of the final system.

The outputs deliver an electrically-isolated Safety Extra Low Voltage (ES1) and low output noise. They are no-load, overload, and short

circuit proof. The electronically controlled short-term peak power capability of up to 150% of the rated output power enables the front

end converters to deliver additional power to start-up motors or to safely operate subsequent circuit breakers. Built-in large sized output

capacitors absorb possible reverse energy, which may be caused by quick deceleration of electromagnetic drives connected directly to

the output. A green LED at the front cover displays the status of the output(s).

The Convert Select Series was designed according to all relevant international safety standards. The converters are approved by Nemko

and CSA and are UL 508 listed. Adequate clearances and creepage distances allow operation in pollution degree 3 environment (with

AC input). All board assemblies are coated with a protective lacquer.

The thermal concept allows operation at full load up to an ambient temperature of 60 °C (LW models) or 70 °C (EW models) in free air

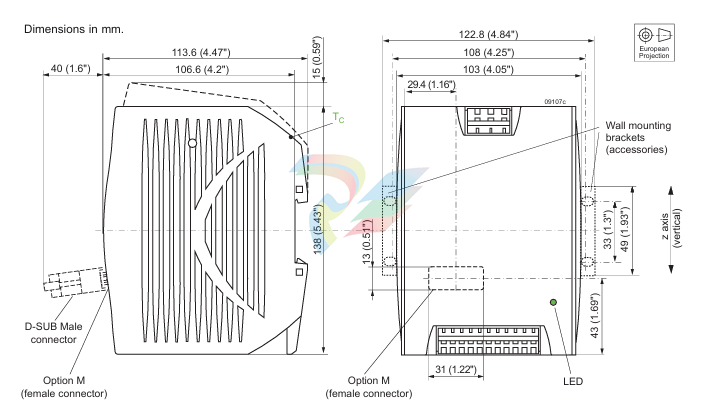

without forced cooling. A rugged DIN snap-fit device allows easy and reliable fixing onto the various 35 mm DIN rail models. The converters

are fitted with cage clamp terminals which are easily accessible from the front. System connectors with screw terminals for use with pre

assembled harnesses, external adjustment of the output voltage as well as various auxiliary functions are available as options.

The letter E stands for improved EMC performance of LW models. Models without E are obsolete.

Product Marking

Basic type designation, applicable safety approval and recognition marks, CE mark, warnings, pin designation, company logo.

Specific type designation, input voltage range, nominal output voltages and currents, degree of protection, batch number, serial

number and data code including production site, version, and date of production.

Functional Description

The W Series converters are primary controlled AC-DC or DC-DC flyback converters with a constant switching frequency of 130 kHz.The power-factor-corrected single-step con version of the input voltage to a low output voltage results in extremely high efficiency.Depending upon the output power, the converters are fitted with one (125 W) or two (250 W) powertrains. Models with two powertrains have one or two outputs. Double-output models exhibit individually regulated power trains.

The input voltage is fed via fuse, filter, and rectifier to the main transformer, designed in planar technique. The input filter with very small input capacitance generates virtually no inrush current. An input transient suppressor protects the converter against high voltage peaks and surges. Input over- and undervoltage lockout as well as input current limitation protect the converter from operation outside of its specification. The input voltage waveform is sensed by the primary control logic to allow active power factor correction,forcing the input current to follow the input voltage waveform.

The secondary side of the main transformer supplies via the rectifier diode a large electrolytic output storage capacitor providing for the hold-up time. Double-output models exhibit an individual control logic each. The output voltage and the output current are measured and fed back to the primary control logic via an optocoupler. A second control loop monitors the output voltage. It disables the output in the case of a failure in the control logic and limits the output voltage. Built-in temperature sensors monitor the internal temperature of each powertrain. If the temperature exceeds the limit, the converter reduces the output power continuously to keep the temperature below its limit. A green LED on the front cover confirms the presence of the output voltage(s).

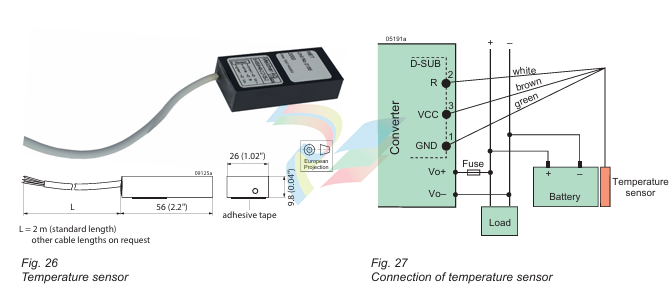

The R input (option R, M1, or M2) allows for external adjustment of the output voltage by means of a resistor or an external voltage source. An external sensor can be connected to the R input and allows for temperature-controlled battery charging (see Accessories).

Output Power Derating

The output power of LW models must be decreased at low input voltage and/or powertrain temperature above 125 °C.

The powertrain temperature depends on the output power, the input voltage, and the cooling method. At low input voltage the losses increase. At the maximum specified environment temperature TA free air convection cooling might be insufficient approaching maximum ambient conditions. As a result, the output power has to be reduced according to the tables below.

Note: The measurements have been made by the approval boards with free air convection cooling according to 62368-1 3rd edition specified ambient temperature TA and with the converter built in a cardboard box according to UL 508 and a specified temperature outside the box Tout .

The tables give a correlation between TA or Tout and the case temperature TC (measuring point TC see Mechanical Data). For models not specified, please contact the Company

EW models need no derating.

Input Fuse and Protection

A fast-blow fuse (Schurter F 6.3A, 5 × 20 mm), protected by a sleeve, is connected to the input L

[W/V]-0.67-1.25-0.67-1.25

or Vi+. EW models have a

smaller fuse (250 V, 4 × 9 mm, SOC NT3 6.3A V009, UL-recognized E-39265). For DC input voltages above 250 V consult the

Installation Instructions.

Converters with option F have large fuses (F6.3A, 5 × 20 mm). The DC input voltage for converters with option F is limited to 250 V. A VDR and a symmetrical input filter form an effective protection against input transients.

An under- and an overvoltage lockout protect the converter, which is disabled below Vi min and above Vi max by an internally generated inhibit signal.

The built-in bridge rectifier (LW models) provides reverse polarity protection at the input if operated from DC. EW models are protected by the (blowing) input fuse in connection with the body diode of the main transistor. Option Q offers a serial diode, but this reduces the efficiency by approx. 1%.

Parallel Operation

Double-output models exhibit an independent control logic each. Both outputs can be con nected in parallel, provided that options

S (included in M1) and R are not used, since they influence only the 2nd output. The two power trains share the current due to their

output voltage droop characteristic.

Up to 3 converters with the same output voltage may be operated in parallel. It is possible to parallel W Series with X Series converters.

Reasonable current sharing is achieved by the droop characteristic. Correct mode of operation is highly dependent upon the wiring of the converters and the impedance of these wires. Use wires with equal length and equal cross sections of min. 1.5 mm2. The best results for parallel operation can be achieved with the wiring shown in fig. 6.

Parallel operation of single-output models using the option R (output voltage adjust) is possible, but not recommended. Refer to f ig. 6; the connections between the pins 8 and 9 (both Vo–) should be as short as possible.

Note: Parallel operation is not possible, if a temperature sensor is connected, as the sensor eliminates the output voltage droop.

Note: For ORing diodes, we recommend to use Schottky diodes, mounted on a common heatsink to avoid thermal run away (or the use of double diodes).

Output Characteristic and Protection

The output characteristic, individual for each powertrain, is rectangular with a droop to ease parallel operation; see fig. 7.

However, a 50% higher output current is possible for a short time, such allowing start-up of loads or charging of capacitors; see fig. 8.

Each output is independently protected against internal overvoltage by means of a second control loop. When the output voltage

exceeds Vo L

, the respective output is disabled.

Overtemperature Protection 1.4 1.6 1.2 1.0 0.8 0.6-- 0.5 0.5 1.5 2.5 s Io / Io nom 05194b 0 1 2 Fig. 8 Short term peak power characteristic: overcurrent versus time (typical values). A built-in temperature sensor protects each powertrain is independently protected against over temperature. When a certain temperature is reached, the concerned powertrain reduces its output power continuously. Thermal Considerations The thermal conditions are influenced by input voltage, output current, airflow, and temperature of surrounding components. TA max is therefore, contrary to TC max , an indicative value only. Caution: The installer must ensure that under all operating conditions TC remains within the limits stated in the table Temperature specifications. Note: Sufficient forced cooling allows TA to be higher than TA max provided that TC max is not exceeded. It is recommended that continuous operation under worst case conditions of the following 3 parameters be avoided: Minimum input voltage, maximum output power, and maximum temperature. Battery Charging and Temperature Sensor The battery charger models exhibit the option M1 and have been designed to charge lead-acid batteries. The R-input allows for connecting a battery-specific temperature sensor, which provides temperature controlled adjust of the trickle charge voltage. This optimizes charging as well as battery life time. Depending upon the cell voltage and the temperature coefficient of the battery, different sensor types are available; see Accessories. Note: Parallel operation is not possible, if the temperature sensor is connected to the paralleled outputs Vo+, as the sensor eliminates the output voltage droop. However, it is possible to insert bleeding resistors in the Vo+ output lines of each converter in order to create a droop of approx. 0.6 V @ Io nom for 24 V outputs (1.2 V @ Io nom for 48V outputs), but this creates considerable power losses.

Installation Instructions

The converters of the W Series are components, intended exclusively for inclusion within other equipment by professional

installers. Installation must strictly follow the national safety regulations in compliance with the enclosure, mounting, creepage,

clearance, casualty, markings and segregation requirements of the end-use application.

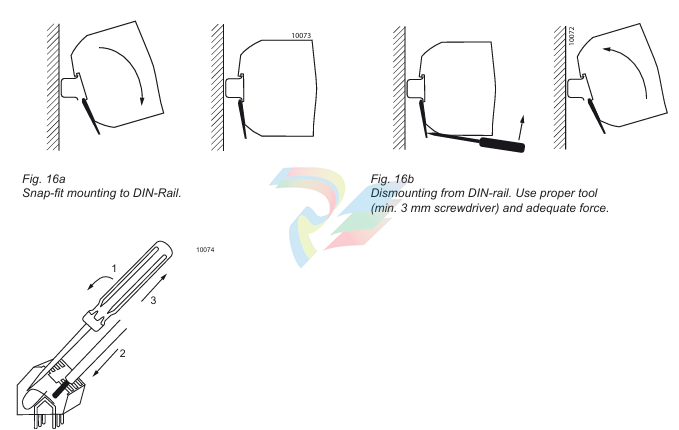

DIN-rail mounting is possible with the built-in snap-fit device on a DIN-rail. This fulfills the mechanical transport re quirements as per ETSI 300019-1-2, class 2 (vertical). To fulfill the requirements of IEC 721-3-2, class 2.1 (vertical), 2 additional fixing brackets HZZ00624-G (see Accessories) must be fitted on the bottom side of the DIN-rail. For heavy duty railway applications, we recommend installing all 4 fixing brackets HZZ00624-G.

Chassis or wall mounting is possible using the universal chassis-mounting brackets HZZ00618-G (see Accessories). Such installa tion complies with IEC 721-3-2, class 2.2 (vertical and horizontal).

Caution: Install the converters vertically, and make sure that there is sufficient airflow available for convection cooling. The minimum space to the next device should be: top/bottom: 30 mm, left/right: 20 mm.

The converters of the W Series are class I equipment: Input terminal 1 ( ) and the output terminals 1 and 11 ( connected to the case. For safety reasons it is essential to connect the input terminal 1 ( ) are reliably ) with protective earth. Output terminals 1 and 11 can be used to connect the output voltage(s) or the load to functional earth.

The phase input (L or Vi+) is internally fused; see Input Fuse. This fuse is de signed to break an overcurrent in case of a malfunction of the converter and is not customer-accessible. External fuses in the wiring to one or both input lines (L and/or N ) may be necessary to ensure compliance with local requirements. A built-in second fuse in the neutral path is available as option F. A second fuse in the wiring to the neutral terminal N or option F is needed if:

• Local requirements demand an individual fuse in each source line

• Neutral and earth impedance is high or undefined

• Phase and neutral of the mains are not defined or cannot be assigned to the corresponding terminals (L Models with Option F: Caution! Double-pole/neutral fusing. to phase and N to neutral). If the converters operate at source voltages above 250 VDC, an external fuse or a circuit breaker at system level should be installed. Caution:

• Installation must strictly follow the national safety regulations.

• Do not open this apparatus

Standards and Approvals The converters of the LW Series with feature E were safety-approved to IEC/EN 62368-1 3rd edition and UL/CSA 60950-1 2nd edition (models without E: IEC/EN 62368-1 3rd edition), IEC 61010-1:C11:2002 (models without E: IEC 61010-1), and EN 50178:1997 (with and without E). The converters are UL508-listed components. The EW models are safety-approved to IEC/EN 62368-1 3rd edition and UL/CSA 60950-1 2nd edition The converters have been designed in accordance with said standards for:

• Class I equipment

• Power supply for building-in, vertical mounting on 35 mm DIN-rail or on a wall

• Overvoltage category II (III for 110 VAC supply)

• Basic insulation between input and case, based on 250 VAC

• Double or reinforced insulation between input and output, based on 250 VAC and 350 VDC.

• Functional insulation between outputs and case.

• Functional insulation between outputs.

• Pollution degree 2 environment. The converters are subject to manufacturing surveillance in accordance with the above mentioned standards and with ISO9001:2015. Operation at Frequencies Greater 60 Hz The LW Series converters have been tested for operation up to 440 Hz. However, the Y and X caps are not approved to such frequency. The leakage currents are higher than at 60 Hz, whereas the output ripple voltage is lower. Leakage Currents with AC Supply Leakage currents flow due to internal leakage capacitance and RFI suppression Y-capacitors. The current values are proportional to the mains voltage and nearly proportional to the mains frequency. They are specified at maximum operating input voltage where phase, neutral, and protective earth are correctly connected as required for class I equipment. Leakage current may exceed 5 mA, if f i > 63 Hz. Railway Applications The W Series converters have been designed observing the railway standards EN 50155 and EN 50121. All boards are coated with a protective lacquer. The EW Series is particularly suitable for connection to 110 V railway batteries. Isolation The electric strength test is performed in the factory as routine test in accordance with EN 62911 and IEC/EN 62368-1 3rd edition and should not be repeated in the field. The Company will not honor warranty claims resulting from incorrectly executed electric strength field tests.

Safety of Operator-Accessible Output Circuits

If the output circuit of a converter is operator accessible, it shall be a ES1 circuit according to 62368-1 3rd edition related safety standards. The converters have ES1 output circuits up to an output voltage of 57.5 V. However, if the isolated outputs are connected to another voltage source or connected in series with a total of >57.5 V the outputs are hazardous. It is the sole responsibility of the installer to ensure the compliance with the relevant and applicable safety regulations.

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

-

UniOP ECT-16-0045 High-Performance Color Touchscreen HMI

-

UniOP ERT-16 - Industrial PLC Workstation

-

UniOP ePAD04-0046 Compact Industrial Interface

-

UniOP BKDR-16 High-Reliability Monochrome Operator Interface

-

UniOP MKDR-04-004 Control Unit Panel

-

UniOP eTOP515 Series 500 HMI

-

Woodward 9907-1199 Advanced CPC-II Current-to-Pressure Converter

-

Woodward 8200-1300 High-Precision 505D Steam Turbine Controller

-

ABB PFSK130 3BSE002616R1 Core Signal Conditioning Unit

-

ABB PFSK165 3BSE027778R1 VP74201-933CW07 Signal Processing and Communication Unit

-

ABB PFSK164 3BSE021180R1 Tension sensor module and processing board

-

ABB 3BSE006505R1 PFSK142 Control board

-

ABB PFSK160A 3BSE009514R1 Regulated High-Capacity 24V DC

-

ABB PFSK162 3BSE015088R1 Signal Conditioning and Processing Board

-

ABB PFSK152 3BSE018877R1 Signal concentrator board

-

ABB PFSK151 3BSE018876R1 High-performance signal processing unit

-

ALSTOM PIB1201A 3BEC0067 Power Interface Board (PIB)

-

ALSTOM PIB310 3BHB0190 Adapter Module / Printed Circuit Board (PCB)

-

ALSTOM PIB102A 3BEB0180 Communication Card / PCB Module

-

ALSTOM BGTR8HE 24491276A1004 High-Frequency Power Controller / Rack Module

-

ALSTOM LC105A-1 Digital Discrete Output (Relay)

-

ALSTOM IR139-1 High-Efficiency Inverter / Control Board

-

ALSTOM AM164 Analog Output / Remote I/O

-

ALSTOM LE109A-1 Power System Control and Monitoring Module

-

ALSTOM UT150-1 PID temperature controller / process control board

-

ALSTOM AL132 AL132A STO0982E01 Control Motherboard / CPU Card

-

ALSTOM AS111-1 Analog Output (AO) Module

-

WATLOW AH116-2 Servo Drive / Control Module

-

WATLOW V4555724-0100 Electromechanical Contactor /Power Switch

-

Alstom KCEU142 Digital Protection Relay

-

ALSTOM MMLG01 Test block

-

WATLOW 999D,999A Digital/Analog Dual-Channel Base Unit

-

WATLOW 998D 998A Digital/Analog Dual-Channel Base Unit

-

WATLOW 999D-11FF-AARG Dual-channel digital unit with universal process outputs

-

WATLOW Wattlo 998D-22KK-ARRG is a high-performance dual-channel digital controller

-

WATLOW 996A Single-loop controller

-

WATLOW 996D-11CC-CUGR Single-loop digital controller

-

WATLOW 996D Single-Channel Digital Temperature/Process Controller

-

WATLOW 997D Digital Dual-Channel Base Unit

-

WATLOW 997A Analog Dual-Channel Variant

-

WATLOW DAC / SDAC Digital-to-Analog / Serial-to-Analog Modules

-

WATLOW MLS300-OIT Operator Interface Terminal (Keypad/Display),Discontinued

-

WATLOW CIM300 Communication Interface Module (EIA-232/485),Discontinued

-

WATLOW MLS300-CIM Control Interface Module

-

WATLOW MLS300-AIM,Analog Input Module (16-channel expansion),Discontinued

-

WATLOW MLS300-PM Processor Module (Central CPU),Discontinued

-

Watlow MLS332 32-Loop Processor Base Unit,Discontinued

-

Watlow MLS316 Multi-loop thermal controller

-

Watlow CLS208 C10000CP high-performance, 8-loop PID temperature controller

-

Watlow CAS 16CLS/CAS Multi-loop temperature controller

-

ABB CP555 1SBP260179R1001 Product Overview

-

Watlow MLS300 Multi-Loop Control System

-

Watlow 997D-11CC-JURG SERIES 997 Vertical Limit Control

-

Watlow CLS216 Multi-Loop PID Temperature Controller

-

Watlow NLS300-CIM316 Multi-Loop Control Interface Module

-

Watlow PPC-TB50 (30280-00) Precision Power Controller

-

ABB 3BSE014227R1 RF533 Central Unit

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)