LAUER for the operating consoles PCS 009, PCS 090, PCS 095, PCS 095.1

LAUER для операционных консолей PCS 009, PCS 090, PCS 095 и PCS 095.1

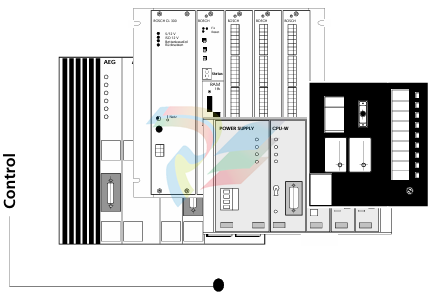

The operating consoles PCStopline offer the highest degree on perfection, unparalled in design and function. PCStopline keeps every thing under control - from the PCSmini to the PCSmaxi, with a superior operating culture and an unlimited setup freedom. PCS, the first programmable operating console with a large selection of "ready-to-use" opera ting functions or operating tools which are simply selected via instructions. You can realize even the most unuasal operating requests at ease and in a minimum of time.

n Machine operation using 8 (PCS 009, PCS 090) or 16 (PCS 095, PCS 095.1)

freely assignable keys. These F01 to F08/F16 labeled keys can be application

specifically inscribed and are provided to the controller as status bits.

n Machine operation using 4 (PCS 009), 16 (PCS 090) or 32 (PCS 095, PCS

095.1) freely usable LEDs. These can be assigned the indicating states ON,

DARK, FLASHING, and INVERSE FLASHING. A green and a yellow LED is allocated

to each function key.

n Display of fixed texts with integrated variable values. The values can be

represented selectably as numerical values or in text format.

n Representation of the contents of 233 words as variables. In addition, 650

external variables can be defined. 9 variable formats (from bit to timer) are

available.

n 3 text groups, 128 operating texts as menu and idle texts, 128 message texts

with up to 332 lines, 5 help texts with up to 32 lines.

n 127 menus with 255 menu nodes each for any menu configurations.

n 4 different deletion modes. For every message, 1 of 4 possible deletion modes

can be selected.

n Modification of the content of any word within the transfer area. Using the

integrated editor all possible representation formats can be setup.

n 7 priority levels for idle text up to help text, 3 message priorities Information,

Warning, Fault. This working-condition related management significantly off

loads the programmable controller program.

n Monitoring of rising or falling edges of 128 consecutive bits. The assignment

of texts, the manage-ment of 3 priority levels (Information, Warnings, and Faults),

keeping the timely sequence as much as possible, organization of the FIRST

MESSAGE, LAST MESSAGE, and CYCLIC DISPLAY, the individually settable dele

tion behaviour, and the representation formats NORMAL and FLASHING are tasks

which are managed by the PCS by itself.

n Communication monitoring (wire-break, short circuit). A very efficient data

transfer is secured by the integrated priority management in connection with the

intelligent package length optimization, the high thruput rate and the fault tole rance.

The simple communication principle of the PCS

Communication between any PLC and the PCS occurs as follows:

The PCS writes in predetermined word areas of the PLC, functions or nominal values,

which the PLC then reads and interprets.

The PLC writes in predetermined word areas functions or actual values, which are

automatically read and interpreted by the PCS. Independently of the PLC there are

maximum 256 words of 16 bit, that is to say 4096 inputs / outputs for the PCS/PLC

communication available.

1 First define the specification and decide on the required PCS (PCS micro, PCS mini, PCS midi or PCS maxi)

2 Allocate the word and bit number to variables (actual- and nominal values).

3 Create the texts for operational guidance and help functions as well as for displays of machine conditions.

4 Determine the message texts and apply these words to them, subdivide the message texts into 3 priority groups n Information n Warnings n Faults and take into consideration the differing cancel modes, display and message modes. Display and message modes can be altered by the PLC at any time.

5 Define the menus and the menu operating texts.

6 Transfer the data file (variables, texts, menus) which was made in the PC or PG under MSDOS/DRDOS or compatible DOS-system, with the software PCSPRO into the PCS.

7 Implement and parameterize the PLC specific operating software (PCS 91.nn, see overall view of information) in the users' programme. 8 Connect the PCS via the adapter cable with the PLC. Test together the operation and control of the PCS and PLC and adjust if necessary

The Variables of the PCS 009, PCS 090, PCS 095, PCS 095.1

Machines produce different parts. Therefore quick and selective alterations of finished sizes and functions (variables) are especially important for increased flexibility. The PCS features a convenient method of processing the variables. 650 external varia bles (freely definable) and 6 internal variables are supervised from the PCS.

The BIT variable ON OFF STOP UP When two possibilities can be selected at an input, the descision is taken by the bit variable. This is in the form of an ON/OFF switch. Every switch position represents an inscription (text) which appears in the display. Each bit variable occupies a bit. A data word can also take on up to 16 differing bit variables or switches. Example: A wood shavings vacuum absorption cleaner shall be switched on or off in bit 2 data word 33. The +/- switch selects the inscription or the switching position. The bit bears the value of the inscription. The first inscription carries the value log 0, the second bears the value log

STRING variable DOWN Version 5 06/95 When two or more possibilities can be selected at an input, the decision is made by the STRING variable. It corresponds to a selector switch. With STRING variables, every switch position is classified with an inscribed text, which appears in the display. Every STRING value carries a data word with up to 256 switch positions. The switch position is deposited in low bytes of the data word. Example: The frame material shall be selected in data word 40. The inscription or switching position is selected with the +/- key. Acceptance follows with the ENTER key.

CSTRING variable The CSTRING variable corresponds to STRING variable. Acceptance follows directly after using the +/- key without ENTER

BCD variable: BCD-1, BCD-2, BCD0-1, BCD0-2

The nominal value of the BCD variable corresponds to that of a BCD thumbwheel switch and the actual value to that of a BCD digital display. The 4 digit (decimal positions) variable BCD-1 is allocated to a word, the 8 digit variable BCD 2 to two consecutive following words 32 bits (W n, W n+1). BCD variables are displayed without pre-zeros. For example a BCD 2 actual value is: 4 2567. The 4 digit variable BCD0-1 is allocated to a word, the 8 digit variable BCD0 to two consecutive following words 32 bits (W n, W n+1). BCD0 variables are displayed with pre-zeros. For example the actual value of a BCD0 is: 0004 2567 Every BCD value is limited to a min/max value. Example: The batch size per window type is written in word 30 as a 4 digit nominal value without min/max limits. BCD CODED 4 + 3 + 2 + 1 +–––––– The nominal value input "8500" takes place with the ten key keyboard of the PCS and is transfered to the word with the ENTER BCD coded key

BINARY variables: BIN-1, BIN-2, BIN-A, BIN-B, VBIN-1, VBIN-2, VBIN-A, VBIN-B, BIN0-1,

BIN0-2, BIN0-A, BIN0-B, VBIN0-1, VBIN0-2, VBIN0-A, VBIN0-B

The nominal value of the BIN variable corresponds to that of a BIN thumbwheel switch and the actual value to that of a BIN digital display. The scaled 16 bit variables (BIN-1 to VBIN-A) are allocated to a word, the 32 bit variables (BIN-2 to VBIN-B) to two consecutive following words (W n, W n+1). The variables (V)BIN(0)-1,2 only differ from those of the (V)BIN(0)-A, B in the way the characters are loaded (V)BIN0-1,2 and (V)BIN-1,2 are with and without pre-zeros repectively VBIN(0)-1,2A,B take the operational sign into consideration. Every (V)BIN variable is limited by a min/max value. In addition the (V)BIN-1,A variables can be scaled. Example: The temperature of the engine brake can be set between 0°C and 70°C. The scaled 16 bit nominal value is written into the word W 45 with a min/ max limit. Example: The window height is adjustable between 750 mm and 1500 mm. The 32 bit nominal value is written into the word 41+42 with a min/max limit. The higher value part remains in W 41, the lower value part in W 42.

WORD variable

The WORD variable is specially suitable for service. Die Darstellung kann sowohl bitweise (KM), hexadezimal (KH) oder byteweise dezimal (KY) erfolgen. An alteration of the bit pattern with the PCS is possible if the WORD variable is defined as a nominal value. WORD VARIABLE BIT CONFIGURATION DATA VALIDITY 00001101 11001110 TIMER VARIABLE TIMER 235.1 Version 5 06/95 Example: The word 33 is to be displayed and altered in the PCS display: Alteration of the nominal value WORD variable takes place in a menu. Display line 1 Display line 2 BIT PATTERN OF WORD 33 0000000000000101 The value of the WORD variable can be changed with the "0" or "1" key. The "+" key switches the pointer one place to the right and with the "–" key, one place to the left. Display line 1 Display- line 2 BIT PATTERN OF WORD 33 1111000011000000 The ENTER key puts the new value into the word

TIMER variable

The TIMER variable allows an input of a 3 digit numeric input (BCD) and a timebase value with 4 selection (displayed as text). Example: Word 100 should be displayed in Timerformat. The content of word 100 is KH1235. If the timebase is defined as ".0", ".1", ".2" and ".3" in the display "235.1" is visible. The value is defined with the key "0"..."9". The selection between base and value is done with the (.) key. The timebase is selectable with + or - key or direct input with "0" bis "3" key

ASCII variable

If an alphabetical nominal value is required (article number, name etc.) the ASCII variable provides it in a simple manner.

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

-

UniOP ECT-16-0045 High-Performance Color Touchscreen HMI

-

UniOP ERT-16 - Industrial PLC Workstation

-

UniOP ePAD04-0046 Compact Industrial Interface

-

UniOP BKDR-16 High-Reliability Monochrome Operator Interface

-

UniOP MKDR-04-004 Control Unit Panel

-

UniOP eTOP515 Series 500 HMI

-

Woodward 9907-1199 Advanced CPC-II Current-to-Pressure Converter

-

Woodward 8200-1300 High-Precision 505D Steam Turbine Controller

-

ABB PFSK130 3BSE002616R1 Core Signal Conditioning Unit

-

ABB PFSK165 3BSE027778R1 VP74201-933CW07 Signal Processing and Communication Unit

-

ABB PFSK164 3BSE021180R1 Tension sensor module and processing board

-

ABB 3BSE006505R1 PFSK142 Control board

-

ABB PFSK160A 3BSE009514R1 Regulated High-Capacity 24V DC

-

ABB PFSK162 3BSE015088R1 Signal Conditioning and Processing Board

-

ABB PFSK152 3BSE018877R1 Signal concentrator board

-

ABB PFSK151 3BSE018876R1 High-performance signal processing unit

-

ALSTOM PIB1201A 3BEC0067 Power Interface Board (PIB)

-

ALSTOM PIB310 3BHB0190 Adapter Module / Printed Circuit Board (PCB)

-

ALSTOM PIB102A 3BEB0180 Communication Card / PCB Module

-

ALSTOM BGTR8HE 24491276A1004 High-Frequency Power Controller / Rack Module

-

ALSTOM LC105A-1 Digital Discrete Output (Relay)

-

ALSTOM IR139-1 High-Efficiency Inverter / Control Board

-

ALSTOM AM164 Analog Output / Remote I/O

-

ALSTOM LE109A-1 Power System Control and Monitoring Module

-

ALSTOM UT150-1 PID temperature controller / process control board

-

ALSTOM AL132 AL132A STO0982E01 Control Motherboard / CPU Card

-

ALSTOM AS111-1 Analog Output (AO) Module

-

WATLOW AH116-2 Servo Drive / Control Module

-

WATLOW V4555724-0100 Electromechanical Contactor /Power Switch

-

Alstom KCEU142 Digital Protection Relay

-

ALSTOM MMLG01 Test block

-

WATLOW 999D,999A Digital/Analog Dual-Channel Base Unit

-

WATLOW 998D 998A Digital/Analog Dual-Channel Base Unit

-

WATLOW 999D-11FF-AARG Dual-channel digital unit with universal process outputs

-

WATLOW Wattlo 998D-22KK-ARRG is a high-performance dual-channel digital controller

-

WATLOW 996A Single-loop controller

-

WATLOW 996D-11CC-CUGR Single-loop digital controller

-

WATLOW 996D Single-Channel Digital Temperature/Process Controller

-

WATLOW 997D Digital Dual-Channel Base Unit

-

WATLOW 997A Analog Dual-Channel Variant

-

WATLOW DAC / SDAC Digital-to-Analog / Serial-to-Analog Modules

-

WATLOW MLS300-OIT Operator Interface Terminal (Keypad/Display),Discontinued

-

WATLOW CIM300 Communication Interface Module (EIA-232/485),Discontinued

-

WATLOW MLS300-CIM Control Interface Module

-

WATLOW MLS300-AIM,Analog Input Module (16-channel expansion),Discontinued

-

WATLOW MLS300-PM Processor Module (Central CPU),Discontinued

-

Watlow MLS332 32-Loop Processor Base Unit,Discontinued

-

Watlow MLS316 Multi-loop thermal controller

-

Watlow CLS208 C10000CP high-performance, 8-loop PID temperature controller

-

Watlow CAS 16CLS/CAS Multi-loop temperature controller

-

ABB CP555 1SBP260179R1001 Product Overview

-

Watlow MLS300 Multi-Loop Control System

-

Watlow 997D-11CC-JURG SERIES 997 Vertical Limit Control

-

Watlow CLS216 Multi-Loop PID Temperature Controller

-

Watlow NLS300-CIM316 Multi-Loop Control Interface Module

-

Watlow PPC-TB50 (30280-00) Precision Power Controller

-

ABB 3BSE014227R1 RF533 Central Unit

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)