Triconex 3351S2 Controller Features

To ensure the highest possible system integrity at all times, the Trident controller includes the following features:

• Provides Triple Modular Redundant (TMR) architecture, whereby each of three identical channels independently executes the application, and specialized hardware and software mechanisms vote all inputs and outputs.

• Withstands harsh industrial environments.

• Integrates the I⁄O module with the termination assembly.

• Enables field installation and repair to be done at the module level while the controller remains online without disturbing field wiring.

• Supports up to 14 I⁄O modules. (If the controller includes AO or PI Modules, up to 10 modules are supported.)

• Provides TriStation and Modbus communication directly from the Main Processor (MP) or from the Communication Module (CM).

• Executes applications developed and debugged using TriStation.

• Provides a dedicated co-processor which controls the input and output modules to reduce the workload of the MP. Each I⁄O module is supported by custom application-specific integrated circuits (ASICs), which scan inputs and perform diagnostics to detect hardware faults. Output module ASICs do the following:– Supply information for voting of output data.– Check I⁄O loop-back data from the output terminal for final validation of the output state.– Perform diagnostics to detect hardware and field-wiring problems.

• Provides integral online diagnostics with adaptive-repair capabilities.

• Allows normal maintenance while the controller is operating, without disturbing the controlled process.

• Supports hot-spare I⁄O modules for critical applications for which prompt service may not be possible.

• Provides integral support for redundant field and logic power sources.

Fault Tolerance

Fault tolerance, the most important capability of the controller, is the ability to detect transient and steady-state error conditions and take appropriate corrective action online. Fault tolerance provides an increase in safety and the availability of the controller and the process being controlled. The Trident controller provides fault tolerance through TMR architecture.

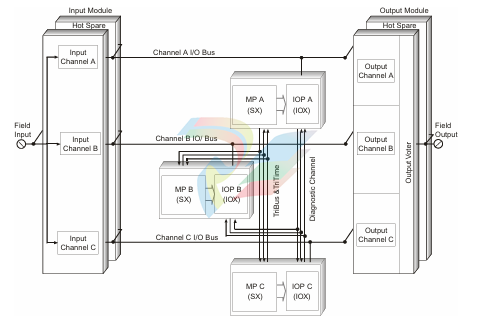

The controller consists of three identical channels (except for the power modules which are dual-redundant). Each channel independently executes an application in parallel with the other two channels. Voting mechanisms qualify and verify all digital inputs and outputs from the field; analog inputs are subject to a mid-value selection process.

Because each channel is isolated from the others, no single-point failure in any channel can pass to another. If a hardware failure occurs in one channel, the faulty channel is overridden by the other channels. Repair consists of removing and replacing the failed module in the faulty channel while the controller is online and without process interruption.

Extensive diagnostics on each channel, module, and functional circuit immediately detect and report operational faults by means of indicators or alarms. All diagnostic fault information is accessible by the application and the operator. The operator can use the diagnostic information to modify control actions or direct maintenance procedures.

Controller Architecture

The controller features TMR architecture to ensure fault tolerance and error-free, uninterrupted control in the event of hard failures of components or transient faults from internal or external sources.

Each I⁄O module houses the circuitry for three independent channels. Each channel on the input modules reads the process data and passes that information to its respective MP. The three MPs communicate with each other using a proprietary, high-speed bus called the TriBus.

Once per scan, the MPs synchronize and communicate with their neighbors over the TriBus. The TriBus forwards copies of all analog and digital input data to each MP and compares output data from each MP. The MPs vote the input data, execute the application, and send outputs generated by the application to the output modules. In addition, the controller votes the output data on the output modules as close to the field as possible to detect and compensate for any errors that could occur between the TriBus voting and the final output driven to the field.

For each I⁄O module, the controller can support an optional hot-spare module. If present, the hot-spare takes control if a fault is detected on the primary module during operation. The hot-spare position is also used for the online hot repair of a faulty I⁄O module.

Main Processor Architecture

A controller contains three MPs. Each MP controls a separate channel and operates in parallel with the other two MPs. A dedicated I⁄O control processor on each MP manages the data exchanged between the MP and the I⁄O modules. A triplicated I⁄O bus, located on the baseplates, extends from one column of I⁄O modules to another column of I⁄O modules using I⁄O bus cables. As each input module is polled, the appropriate channel of the I⁄O bus transmits new input data to its MP. The input data is assembled into a table in the MP and is stored in memory for use in the voting process.

The individual input table in each MP is transferred to its neighboring MP over the TriBus. After this transfer, voting takes place. The TriBus uses a programmable device with direct memory access to synchronize, transmit, and compare data among the three MPs. If a disagreement occurs, the signal value found in two of three tables prevails, and the third table is corrected accordingly. One-time differences which result from sample timing variations are distinguished from a pattern of differing data. Each MP maintains data about necessary corrections in local memory. Any disparity is flagged and used at the end of the scan by the built-in fault analyzer routines to determine whether a fault exists on a particular module.

The MPs send corrected data to the application. The 32-bit MP executes the application in parallel with the neighboring MPs and generates a table of output values that are based on the table of input values according to user-defined rules.The I⁄O control processor on each MP manages the transmission of output data to the output modules by means of the I⁄O bus.

Using the table of output values, the I⁄O control processor generates smaller tables, each corresponding to an individual output module. Each small table is transmitted to the appropriate channel of the corresponding output module over the I⁄O bus. For example, MP A transmits the appropriate table to channel A of each output module over I⁄O bus A. The transmittal of output data has priority over the routine scanning of all I⁄O modules.

Each MP provides a 16-megabyte DRAM for the user-written application, sequence-of-events (SOE) and I⁄O data, diagnostics, and communication buffers. (For more information about SOE, see the Sequence of Events Recorder User's Manual.) The application is stored in flash EPROM and loaded in DRAM for execution. The MPs receive power from redundant 24 volts DC power sources. If an external power failure occurs, all critical retentive data is stored in NVRAM. A failure of one power source does not affect controller performance. If the controller loses power, the application and all critical data are retained indefinitely.

Bus and Power Distribution

The triplicated I⁄O bus, as shown on page 8, is carried baseplate-to-baseplate using Interconnect Assemblies, I⁄O Extender Modules, and I⁄O bus cables. The redundant logic power distribution system is carried using Interconnect Assemblies and I⁄O Extender modules.

serial links operating at 25 megabits per second. The TriBus synchronizes the MPs at the beginning of a scan. Then each MP sends its data to its upstream and downstream neighbors. The TriBus takes the following actions:

• Transfers input, diagnostic, and communication data

• Compares data and flags disagreements with the output of the previous scan and program memory

An important feature of the Trident controller architecture is the use of a single transmitter to send data to both the upstream and downstream MPs. This ensures that the same data is received by the upstream processor and the downstream processor.

Field signal distribution is local to each I⁄O baseplate. Each I⁄O module transfers signals to or from the field through its associated baseplate assembly. The two I⁄O module slots on the baseplate tie together as one logical slot. The right or left position holds the active I⁄O module and the other position holds the hot-spare I⁄O module. Each field connection on the baseplate extends to both active and hot-spare I⁄O modules. Consequently, both the active module and the hot-spare module receive the same information from the field termination wiring. A triplicated I⁄O bus transfers data at 2 megabits per second between the I⁄O modules and the MP. The I⁄O bus is carried baseplate-to-baseplate and can be extended to multiple columns of I⁄O modules. Each channel of the I⁄O bus runs between one MP and the corresponding channel on the I⁄O module. The I⁄O bus extends between DIN rails using a set of three I⁄O bus cables. Logic power for the modules on each DIN rail is distributed using two independent power rails. Each module along the DIN rail draws power from both power rails through redundant DC-DC power converters.

Each channel is powered independently from these redundant power sources.

Controller Communications

The controller can communicate directly to TriStation and other devices through the Main Processor Module and the Communication Module.

Main Processor Module

Each MP can provide direct TriStation and Modbus communication. Each MP provides:

• One Tristation (Ethernet) port for downloading an application to the controller and uploading diagnostic information.

• One Modbus RS-232/RS-485 serial port which acts as a slave while an external host computer is the master. Typically, a distributed control system (DCS) monitors—and optionally updates—the controller data directly though an MP.

Communication Module

The Communication Module (CM) provides an optional, three-to-one interface to

the MPs that supports various protocols for communication with external hosts. A

single controller supports up to two CMs on one CM Baseplate. Each CM operates

independently. Two CMs can provide redundant communication connections or

independent communication ports.

Each CM provides three RS-232/485 serial ports and two Ethernet ports. These ports support a variety of communication methods, protocols, and physical media types that enable the controller to communicate with:

• External host computers

• Distributed control systems (DCS)

• Open networks

• Network printers

• Other Trident or Tricon V9 controllers

Input/Output Modules

The controller manages the data exchanged between the MP and the following I⁄O modules:

• Analog Input Module

• Analog Output Module

• Digital Input Module

•Digital Output Module

• Pulse Input Module

• Solid-State Relay Output Module

Analog Input Module

places the results into a table of values. Each input table is passed to its associated MP using the corresponding I⁄O bus. The input table in each MP is transferred to its neighbors across the TriBus. The middle value is selected by each MP and the input table in each MP is corrected accordingly. In TMR mode, the mid-value data is used by the application; in duplex mode, the average is used. Each AI Module is guaranteed to remain in calibration for the life of the controller; periodic manual calibration is not required. Special self-test circuitry is provided to detect and alarm all stuck-at and accuracy fault conditions in less than 500 milliseconds, typically. This safety feature allows unrestricted operation under a variety of multiple-fault scenarios.

Analog Output Modules

AO Module receives three tables of output values, one for each channel from the corresponding Main Processor. Each point on each channel has its own digital-to analog converter (DAC). One of the three channels is selected to drive the analog outputs. The outputs of the selected channel are continuously verified by I⁄O loop back inputs from each point, which are read by all three channels. If a fault occurs in the driving channel, the channel is declared faulty, is disabled, and a new channel is selected to drive the field device. The selection of the driving channel alternates among the channels so that all three channels are periodically tested. Each AO Module is guaranteed to remain in calibration for the life of the controller; periodic manual calibration is not required.

Digital Input Module

A Digital Input Module contains the circuitry for three identical channels (A, B, and C). Although the channels reside on the same module, they are completely isolated from each other and operate independently. Each channel conditions signals independently and provides optical isolation between the field and the controller. A fault on one channel cannot pass to another. In addition, each channel contains a proprietary ASIC which handles communication with its corresponding MP, and supports run-time diagnostics. Each of the three input channels measures the input signals from each point on the baseplate asynchronously, determines the respective states of the input signals, and places the values into input tables A, B, and C, respectively. Each input table is interrogated at regular intervals over the I⁄O bus by the I⁄O communication processor located on the corresponding MP. For example, MP A interrogates Input Table A over I⁄O Bus A. Special self-test circuitry is provided to detect and alarm all stuck-at and accuracy fault conditions in less than 500 milliseconds, typically. This safety feature allows unrestricted operation under a variety of multiple-fault scenarios. The input diagnostics are specifically designed to monitor devices which hold points in one state for long periods of time. The diagnostics ensure complete fault coverage of each input circuit even if the actual state of the input points never changes.

Digital Output Module

A DO Module contains the circuitry for three identical, isolated channels. Each channel includes a proprietary ASIC which receives its output table from the I⁄O communication processor on its corresponding main processor. All DO Modules use special quad output circuitry to vote on the individual output signals just before they are applied to the load. This voter circuitry is based on parallel-series paths which pass power if the drivers for channels A and B, or channels B and C, or channels A and C command them to close—in other words, 2-out-of-3 drivers are voted on. The quad output circuitry provides multiple redundancy for all critical signal paths, guaranteeing safety and maximum availability. A DO Module periodically executes an output voter diagnostic (OVD) routine on each point. This safety feature allows unrestricted operation under a variety of multiple-fault scenarios.

OVD detects and alarms two different types of faults:

• Points— all stuck-on and stuck-off points are detected in less than 500 milliseconds, typically.

• Switches—all stuck-on or stuck-off switches or their associated drive circuitry are detected.

During OVD execution, the commanded state of each point is momentarily reversed on one of the output drivers, one after another. Loop-back on the module allows each ASIC to read the output value for the point to determine whether a latent fault exists within the output circuit. The output signal transition is guaranteed to be less than 2 milliseconds (500 microseconds is typical) and is transparent to most field devices. For devices that cannot tolerate a signal transition of any length, OVD can be disabled. OVD is designed specifically to check outputs which typically remain in one state for long periods of time. The OVD strategy for a DO Module ensures full fault coverage of the output circuitry even if the commanded state of the points never changes.

Pulse Input Module

On a PI Module, each channel measures the input frequency independently. Special algorithms, optimized for accurately measuring the speed of rotating machinery, are used to compensate for irregularly spaced teeth on timing gear or for periodic acceleration/de-acceleration. The results are placed into a table of values. Each input table is passed to its associated MP using the corresponding I⁄O bus. The input table in each MP is transferred to its neighbors across the TriBus. The middle value is selected by each MP and the input table in each MP is corrected accordingly. In TMR mode, the mid-value is used by the application; in duplex mode, the average is used. Special self-test circuitry is provided to diagnose the health state of all input points, even when an active signal is not present. Each PI Module is guaranteed to remain in calibration for the life of the controller; periodic manual calibration is not required.

Solid-State Relay Output Module

On a Solid-State Relay Output (SRO) Module, output signals are received from the MPs on each of three channels. The three sets of signals are voted and the voted data is used to drive the 32 individual relays. Each output has a loop-back circuit which verifies the operation of each relay switch independently of the presence of a load. Ongoing diagnostics test the operational status of the SRO Module.

The SRO Module is a non-triplicated module for use on non-critical points which are not compatible with high-side, solid-state output switches; for example, interfacing with annunciator panels.

TRICONEX 3636R/3636T

TRICONEX 3700A

TRICONEX 3701

TRICONEX 3703E

TRICONEX 3704E

TRICONEX 3706A

TRICONEX 3708E

TRICONEX 3720

TRICONEX 3805E

TRICONEX 3805H

TRICONEX 3806E

TRICONEX 3807

TRICONEX 5101

TRICONEX 5201

TRICONEX 5351

TRICONEX 5361

TRICONEX 5352

TRICONEX 5381

TRICONEX 5382

TRICONEX 5301

TRICONEX 5401

TRICONEX 5401L

TRICONEX 5402

TRICONEX 5451

TRICONEX 5481

TRICONEX 2101

TRICONEX 2281

TRICONEX 2291

TRICONEX 2292

TRICONEX 2301

TRICONEX 2302

TRICONEX 2302A

TRICONEX 2342

TRICONEX 2342A

TRICONEX 2351

TRICONEX 2352

TRICONEX 2352A

TRICONEX 2354

TRICONEX 2354A

TRICONEX 2361

TRICONEX 2381

TRICONEX 2401

TRICONEX 2402

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

-

ABB IGBT 5SDF0860H0003 5SDF1045H0002 unit

-

ABB TC512V1 3BSE018059R1 RS485 Twisted pair Modem

-

ABB DO880 S800HI 3BSE028602R1 Digital Output

-

ABB GDD360C 3BHE047217R0101 Advanced Automation Solution

-

ABB UCD240A101 3BHE022287R0101 controller unit

-

ABB AC800F Ethernet Module AM811F 3BDH000050R1

-

ABB AC800F Module AM801F 3BDH000040R1

-

ABB SD802F 3BDH000012R1 POWER UNIT

-

ABB operation panel PM820-2 3BSE010798R1 system module

-

ABB operation panel PM820-1 3BSE010797R1 system module

-

ABB CI857K01 3BSE018144R1 INSUM Ethernet Interface

-

ABB PM861/PM861AK01 and TP830 Processor Unit

-

ABB SA811F 3BDH000013R1 Power Supply 115/230 VAC

-

ABB 751010R0815 1VC1T0374A00R unit

-

5SGY35L4510 Robot high voltage board Brand ABB

-

ABB HVC-02B 3HNA024966-00103 Robot high voltage board Brand HVC02B

-

ABB SLMG99 UNIT

-

ABB 086406-002 PWA.SIOC. SMART I/O CALIP 086407-502

-

ABB UCD208A101 3BHE020018R0101 UNIT

-

ABB UAD154A 3BHE026866R0101 UNIT

-

ABB GCD207B101 3BHE024642R0101 controller card

-

ABB TB820V2 S800 Modulebus module 3BSE013208R1

-

ABB UDD406A 3BHE041465P201 Control unit

-

ABB PPD113B01-10-150000 3BHE023784R1023 unit CPU module

-

ABB 5SHY35L4512 3BHE014105R0001 5SXE08-0166 IGCT unit

-

ABB Backplane Uni Type3+housing FETD685A1156U01

-

ABB 07DC91C GJR5251400R0202 Digital input and output Unit

-

ABB UNS2881b-P,V1 3BHE009319R0001 UNS2881BPV1 Inspirational system

-

ABB UNS2880B-P,V2 3BHE014967R0002 UNS2880B-PV1 Inspirational system

-

ABB CI810B 3BSE020520R1 AF 100 Fieldbus Comm. Interface

-

ABB FM9925a-E HIEE451116R0001 Interface Module Card

-

Bently 2300/25 0002 Vibration Monitors

-

Bently 2300/20 0002 Vibration Monitors

-

ALSTOM VP327 020-23EU 75X-6025-29 Control mainboard VP32702

-

ABB NE802 3BSE080237R1 Industrial switch

-

ABB 3BSE080207R1 NE810 Industrial switch

-

MOTOROLA MVME2400 VME Processor Modules

-

ABB 3BHE021481R0001 intelligent current distr UNIT

-

MOTOROLA MVME2434 VME Processor Modules

-

METSO PDP606 CONTROLLER unit

-

WOODWARD PG-PL-29 Governor 8577-613

-

GE IS230TNRLH1B Combination module kit Mark VI

-

GE IS230TNAIH2C Combination module kit Mark VI

-

ABB 3ASC25H204 DAPU 100 Control board I/O

-

ABB 3BHE014070R0101 V PPC905AE101 CCB-2 COMPLETE

-

ABB PRC3BSE050198R1 PM866K01 Processor Unit

-

Kongsberg RAIV400 600370 Remote Analogue Input

-

ABB SPSED01 event sequence module

-

ABB HIEE300900R0001 PP C322 BE01 PSR-2 processor + fieldbus

-

ABB 3BHE003604R0102 UFC765AE102 circuit board

-

ABB ACU-01B 3HNA024871-001 Robot controller

-

ABB XVC770BE101 3BHE021083R0101 circuit board

-

ABB UAC383AE01 HIEE300890R0001 Module

-

ABB REF610C11LCNP FEEDER PROTECTION RELAY

-

ABB MT91 Operator Panel MT-91-ARC FP A

-

ABB XUD194 XUD194A 3BHC018137R0001 module base

-

ABB 5SHY4045L0001 3BHB018162 3BHE009681R0101 GVC750BE101

-

ABB G2000A5.7ST graphical operation panel (HMI)

-

ABB 3BHE017628R0002 PPD115A02 SG579989013

-

ABB Motor Protection and Control REM615 Product Guide

-

ABB PFTL101B 3BSE004185R1 2.0KN sensor

-

ABB PFCL201CE 50KN 3BSX802939-108 sensor

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)