WOODWARD EGCP-3 Engine Generator Control Package LS (Load Sharing)

General Information

Introduction

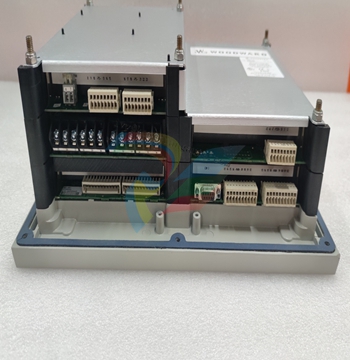

This manual describes the Woodward EGCP-3 Engine Generator Control

Package, Load Sharing (LS) model, part number 8406-113. It provides

description, operation, tuning, and troubleshooting information for EGCP-3 digital

controls. The details on installation, wiring, communication, Regulatory Notes

and Warnings are in the EGCP-3 Installation Manual 26122. The EGCP-3 LS is

intended for power generator applications where multiple control/generators will

supply an isolated bus, or operate in parallel with a Mains (Utility) bus. The

EGCP-3 can perform engine start/stop sequencing. For isolated load operation,

the control will operate in isochronous speed control. For a multiple engine bus,

up to 16 generators can share load, operate in BaseLoad, or process control

modes.

The generator should be equipped with a sync check relay, circuit breaker, and other fast-acting protective relays as required by local codes and practices to protect against damage to the generator with possible personal injury, loss of life, or property damage.

The overspeed shutdown device, sync check relay, circuit breaker, and other fast-acting protective relays must be totally independent of the prime mover control system. An overtemperature or overpressure shutdown device may also be needed for safety, as appropriate.

Protective Earth (PE) must be connected to the termination point on the backside of the unit next to the label with the symbol (or 1 of 3 other like termination points without label) to reduce the risk of electric shock. This connection will be made using a thread-forming screw. The conductor providing the connection must have a properly sized ring lug and wire larger than or equal to 4 mm² (12 AWG).

HIGH VOLTAGE—The calibration and checkout procedure should only be performed by authorized personnel knowledgeable of the risks posed by live electrical equipment.

The installation must include the following:

The power supply mains should be properly fused according to the installation instructions and the appropriate wiring requirements.

A switch or circuit breaker must be included in the building installation in close proximity to the equipment and within easy reach of the operator, and must be clearly marked as the disconnecting device for the equipment. The switch or circuit breaker will only remove power to the unit—hazardous voltages may still be connected to other terminals on the unit.

Application and Functions

The EGCP-3 control is a microprocessor-based generator load control designed

for use with a separate speed control and an automatic voltage regulator to

provide synchronizing, paralleling, loading and unloading. All transitions between

EGCP-3 functions are coordinated to provide smooth operation.

EGCP-3 LS Functions:

Display/Keypad Interface for local setup/monitoring

Engine Start/Stop Sequence Control

Monitor of Generator and Bus power

Unit sequencing and individual unit protection

Engine Protection and Monitoring

Synchronizer with speed, phase, voltage matching, token passing for dead bus closure, and multiple unit synchronizing

KW Control with automatic generator loading and unloading for bumpless load transfer

Droop, BaseLoad, Isochronous, and Isochronous load sharing control capability

Frequency and voltage trimming in Isochronous mode

Communication bus between Master Control and other LS units

Master/Slave Process control for cogeneration, import/export, pressure control, or other processes

KVAR/PF Control and bus /PF sharing

Individual generator stable timing

Built in diagnostics

Generator and Bus Protective Relaying

Generator Power & Energy Metering

Modbus® * and ServLink communications for remote HMI/PLC connections

HMI/Front Panel Display

The EGCP-3 has a keypad and two 4-line display panels on the front cabinet

mounted chassis. The display can be used to configure and set up the control for

site specific requirements. The display is also used in normal operating service to

monitor operation and view alarm data. All functions performed and parameters

monitored by the front panel are also available through the three serial ports.

These ports can be configured to use Woodward Watch Window software, an

external HMI and Modbus communication, or ServLink DDE software.

Engine Control

The EGCP-3 control performs stop and start logic for both gas and diesel

reciprocating engines. The starting logic includes: pre-glow capability, separate

enabling for ignition, fuel pump/FSOV logic, and a configurable pause at idle. The

engine stop function includes: controlled cooldown, soft shutdown logic and

emergency stop logic. The start and stop logic includes closing and opening of

generator breaker. Typical protections such as over speed, coolant temperature,

oil pressure, and battery voltage are also provided. Configurable digital and

analog fault inputs are provided for use with temperature, pressure, or level

switches. All the faults may be disabled when not needed. In addition to

automatic modes, Manual start and stop for the engine is possible. The circuit

breaker can be closed manually to load the generator in the selected load control

mode (Process, Droop, BaseLoad, Isochronous) when manual control is desired.

Synchronizer

The EGCP-3 control uses digital signal processing techniques to derive both true

RMS voltages and relative phase of the fundamental frequencies of the bus and

generator voltage wave forms. Digital signal processing techniques offer

significantly improved measurement accuracy in the presence of waveform

distortions, particularly since the phase measurement does not depend on zero

crossings of the waveforms.

Either phase matching or slip frequency synchronizing may be selected. Phase matching method controls the engine speed to give zero speed error and minimal phase error between the generator and bus; this provides rapid synchronizing for critical standby power applications. Slip frequency synchronizing guarantees a fixed speed difference between generator and bus. This insures the generator to be faster than the bus and initial power flow is out of the machine for larger generators. For both synchronizing methods, the EGCP-3 control uses actual slip frequency and breaker delay values to anticipate a minimum phase difference between bus and generator at actual breaker closure.

The synchronizer can sense a dead local bus and close the generator circuit breaker automatically when safe to do so. The network communication between EGCP-3 control assures that multiple generators cannot close simultaneously onto a dead bus.

There are four synchronizer modes of operation: Run, Check, Permissive, Off. The mode can be selected through Watch Window, the front panel display, or Modbus. The last mode selected by any of these interface methods will be the mode of operation.

Additional synchronizer features include: voltage matching, time delayed automatic multi-shot reclosing, and a synchronizer timeout alarm. Raise and lower inputs can be used to manually adjust speed for manual synchronizing. Voltage raise and lower inputs can be used to manually adjust voltage for manual voltage matching. Each of these features may be enabled or disabled during setup.

Load Control

When the generator circuit breaker is closed, the LS model is in Isochronous and

will Load Share with other units also connected to the bus. The speed bias output

will control the load of each engine by slight changes to the speed control’s

speed reference. When the breaker is open, the EGCP-3 will be in droop

operation. Another mode of Load control is BaseLoad; it begins at breaker

closure when the load control function takes control of the EGCP-3 speed bias

output directly from the synchronizer. The matching of synchronizer slip

frequency to initial load (unload trip level) can result in a bumpless transfer to

load control. On command, the adjustable ramp allows smooth, time-controlled

loading into Load Sharing, BaseLoad, or process control. A ramp pause switch

input allows holding of the load ramp for warm-up or other purposes. Process

Control is a derivative of BaseLoad operation. In this control mode, one genset

may be assigned as a master, to control the loading of other gensets on the bus.

The EGCP-3 control provides switch inputs to allow raising or lowering the internal BaseLoad reference. The control also provides a 4–20 mA (or 1–5 Vdc) analog input for remote load setpoint, if desired. The load reference can also be set through a Modbus or ServLink DDE communication interface.

When unloading, an adjustable unload ramp provides time controlled unloading to the unload trip level. When load reaches the unload trip level, the control will hold the load at the unload value, the breaker can then be opened manually to remove the genset from service. The ramp pause switch can be used to stop the load ramp at its present value for cool-down or other purposes.

The load and unload ramps also provide smooth transition between BaseLoad and process control any time the operating mode is changed.

The EGCP-3 control includes several additional load control features:

Simple load droop operation provides safe operation in parallel bus applications in the event of a circuit breaker aux contact failure.

Isochronous operation when the bus is isolated.

Adjustable load switch output with independent pick-up and drop-out points provides a signal when the specified load is exceeded.

Process Control

A cascade process controller is provided for cogeneration, import/export control,

pond level maintenance, pressure maintenance, or other application. An

adjustable bandwidth input filter, flexible controller adjustments, an adjustable

deadband, and direct or indirect control action, allow the process control to be

used in a wide variety of applications.

A 4–20 mA (or 1–5 Vdc) process transmitter provides the process signal to the EGCP-3 control. The control includes an internal digital process reference which may be controlled by raise and lower switch contact inputs or by an external 4 20 mA (or 1–5 Vdc) process reference, or by a Modbus or ServLink communication interface. The output of the process control provides the cascade load reference to the BaseLoad control.

Adjustable ramps allow smooth entry to or exit from the process control mode. When the process control mode is selected, an adjustable ramp moves the load reference in a direction to reduce the process control error. When the error is minimized, or the reference first reaches either the specified high or low load pick-up limits, the process controller is activated. When unloading from the process control, an adjustable unload ramp provides time controlled unloading to the unload trip level. When load reaches the unload trip level, the EGCP-3 control automatically issues a breaker open command to remove the generator set from the system. The ramp pause switch input allows holding of the load ramp for cool-down or warm-up purposes.

Additional functions include selectable and adjustable process high and low limit switches and alarm activation.

When multiple gensets and EGCP-3 LS controls are connected to a bus in process control mode one unit is automatically assigned as the “Process Master”. It’s process control loop then dictates through the LON network the load levels of other gensets on the bus.

VAR/PF Control

The VAR/PF functions control the reactive power component of the generator in

parallel systems. The reactive load mode can be configured for VAR or Power

Factor control. The controller compares the reactive load on the generator with

an adjustable internal reference and makes corrections to the setpoint of the

Automatic Voltage Regulator (AVR) until the desired reactive power is obtained.

The reactive power level can be maintained while also controlling real load

through the generator breaker. The analog voltage bias output can be directly

connected to compatible voltage regulators. The control also has raise and lower

contact outputs to activate a voltage regulator MOP when an analog input is not

provided on the AVR. The EGCP-3 control has a selectable voltage range alarm

that is activated if the analog output to the voltage regulator reaches high or low

saturation. The EGCP-3 control also has selectable and adjustable high and low

voltage limit switches and alarm outputs.

The EGCP-3 control provides switch inputs to allow raising or lowering the generator voltage reference. The control also provides a 4–20 mA (or 1–5 Vdc) analog input for kVAR/PF setpoint control, if desired. The kVAR/PF reference can also be set through a Modbus or ServLink DDE communication interface.

While the EGCP-3 is controlling unit load to accomplish real load (kW) sharing, the voltage of the generators in parallel will be controlled to accomplish equal Power Factor levels of each generator.

ATS Control

ATS functions are not included in the LS model of EGCP-3. A Master Control (MC) is used to control the mains circuit breakers and local bus circuit breakers to perform ATS functions.

Peaking and Demand Operation

The LS model does not have Peaking and Demand functions. This function is

provided from an MC control that provides the interface with the mains(utility) and

LS units.

Genset Sequencing

While the details of how to start and stop a genset is determined by the Engine

Control sequence, when to initiate a start or stop is the function of the sequence

configuration. The starting and stopping of Gensets is closely associated with the

configuration of the system bus structure and genset characteristics. All EGCP-3

LS and EGCP-3 MC controls on a common network communicate their operation

status and the mains and bus status over a Echelon Network (LON). Systems

with up to 16 gensets, and/or four local bus segments, and/or two mains

connections for a split bus arrangement can be configured. When automatic

connection(s) to the mains is configured an EGCP-3 MC connected to the LON

network is required. The user can configure the criteria used to start and stop

genset(s) and the priority of which genset is the next to start or stop.

A typical start/stop sequence would be:

When the units on a bus segment are above a configured Maximum Load Level or above their 100% Load Level, a start command will be given to the next scheduled unit.

When the units on this bus segment are below a configured Minimum Load

Level, a stop command will be given to the next scheduled unit.

Power and Energy Metering

The digital signal processing techniques are used to provide significantly improved accuracy and speed of response over conventional analog measurement techniques. Accuracy is improved using rapid sampling of the voltage and current signal waveforms and developing a true RMS measurement. Measuring true RMS power allows optimal accuracy, even in the presence of power line distortions.

The PowerSense board receives the PT and CT inputs for both the generator and bus for calculation of parameters for the EGCP-3 to use in system control. The algorithms used are based on IEEE 1459-2000. For the generator and bus the following parameters are provided: Hz, Vac, Amps, W, VA, VAR, PF, Phase, Voltage harmonics, Current harmonics, Negative Phase Sequence Voltage, Negative Phase Sequence Current.

Available for selection at the 4–20 mA analog outputs: Synchroscope, Generator metering, Mains metering

Protective Relaying

The PT and CT inputs were designed for accurate voltage and current monitoring

in applications of display and control. They are not designed for high speed,

sub-cycle, or cycle-to-cycle protective relaying though time delay protective

relaying can be used.

The EGCP-3 should not be used as the only means for detecting

voltage or current disturbances, dead bus conditions, or overcurrent

conditions. The generator should be equipped with a sync check relay,

circuit breaker, and other fast-acting protective relays as required by

local codes and practices to protect against damage to the generator

with possible personal injury, loss of life, or property damage. The

sync check relay, circuit breaker, and other fast acting protective

relays must be totally independent of the EGCP-3.

Alarms can be configured for generator and bus protective relay (i.e. Reverse

power, Under Voltage) functions. Time delay, and separate warning and trip

thresholds can be set. A complete list of protective relay functions available is

given in Chapter 3. Current based protections are implemented using the

ANSI/IEEE C37.112 Very Inverse curve.

Communications

The EGCP-3 includes three serial ports for simultaneous connection to remote

HMI, PLC, remote control and monitoring equipment. The remote monitoring and

interface can be by Modbus tools or Woodward ServLink tools. Configuration of

the EGCP-3 may be done from the front panel or through a serial port using

Woodward Watch Window software. The Watch Window software allows easy

configuration in a Windows environment.

Woodward 2301A Load Sharing Speed Control 9905-377

Woodward AMG 2 Engine/Generator Controller (8440-1273G)

Woodward 8272-683 Digitale Riferimento Unit

Woodward 8272-683 Digital Reference Unit

Woodward 8272-683 Numrique RF unit

Woodward 8272-683 Digital Reference Unidad

Woodward 8272-653 electric operated potentiometer sn.10067.1006666666686

Woodward 5484-721 motor

Woodward EPS1000 engine status light

Woodward 8270-990 signal converter

Woodward Motor Overload Relay 1765-825 4

Woodward 8901-037 booster servo motor

Woodward 9905-021

Woodward 9905-021

Woodward 8270-1082

APECS driver 0175-24ASLS SA-4573-24 24VDC

APECS actuator 0175-24 ASLS SA-4573-24 24VDC

Woodward SPM-D1145B/LSXR

Woodward MFR13/MFR13

Woodward MFR 1371M/MFR1371M

Woodward DYN1-10654-000-0-24

Woodward BN1-400/BN1400

Woodward 9907-866/9907866

Woodward 9907-018/9907018

Woodward 9907-014/9907014

Woodward 9905-384/9905384

Woodward 9905-090/9905090

Woodward 8440-2050/84402050

Woodward 84401614/84401614

Woodward 8406-113/8406113

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

-

UniOP ECT-16-0045 High-Performance Color Touchscreen HMI

-

UniOP ERT-16 - Industrial PLC Workstation

-

UniOP ePAD04-0046 Compact Industrial Interface

-

UniOP BKDR-16 High-Reliability Monochrome Operator Interface

-

UniOP MKDR-04-004 Control Unit Panel

-

UniOP eTOP515 Series 500 HMI

-

Woodward 9907-1199 Advanced CPC-II Current-to-Pressure Converter

-

Woodward 8200-1300 High-Precision 505D Steam Turbine Controller

-

ABB PFSK130 3BSE002616R1 Core Signal Conditioning Unit

-

ABB PFSK165 3BSE027778R1 VP74201-933CW07 Signal Processing and Communication Unit

-

ABB PFSK164 3BSE021180R1 Tension sensor module and processing board

-

ABB 3BSE006505R1 PFSK142 Control board

-

ABB PFSK160A 3BSE009514R1 Regulated High-Capacity 24V DC

-

ABB PFSK162 3BSE015088R1 Signal Conditioning and Processing Board

-

ABB PFSK152 3BSE018877R1 Signal concentrator board

-

ABB PFSK151 3BSE018876R1 High-performance signal processing unit

-

ALSTOM PIB1201A 3BEC0067 Power Interface Board (PIB)

-

ALSTOM PIB310 3BHB0190 Adapter Module / Printed Circuit Board (PCB)

-

ALSTOM PIB102A 3BEB0180 Communication Card / PCB Module

-

ALSTOM BGTR8HE 24491276A1004 High-Frequency Power Controller / Rack Module

-

ALSTOM LC105A-1 Digital Discrete Output (Relay)

-

ALSTOM IR139-1 High-Efficiency Inverter / Control Board

-

ALSTOM AM164 Analog Output / Remote I/O

-

ALSTOM LE109A-1 Power System Control and Monitoring Module

-

ALSTOM UT150-1 PID temperature controller / process control board

-

ALSTOM AL132 AL132A STO0982E01 Control Motherboard / CPU Card

-

ALSTOM AS111-1 Analog Output (AO) Module

-

WATLOW AH116-2 Servo Drive / Control Module

-

WATLOW V4555724-0100 Electromechanical Contactor /Power Switch

-

Alstom KCEU142 Digital Protection Relay

-

ALSTOM MMLG01 Test block

-

WATLOW 999D,999A Digital/Analog Dual-Channel Base Unit

-

WATLOW 998D 998A Digital/Analog Dual-Channel Base Unit

-

WATLOW 999D-11FF-AARG Dual-channel digital unit with universal process outputs

-

WATLOW Wattlo 998D-22KK-ARRG is a high-performance dual-channel digital controller

-

WATLOW 996A Single-loop controller

-

WATLOW 996D-11CC-CUGR Single-loop digital controller

-

WATLOW 996D Single-Channel Digital Temperature/Process Controller

-

WATLOW 997D Digital Dual-Channel Base Unit

-

WATLOW 997A Analog Dual-Channel Variant

-

WATLOW DAC / SDAC Digital-to-Analog / Serial-to-Analog Modules

-

WATLOW MLS300-OIT Operator Interface Terminal (Keypad/Display),Discontinued

-

WATLOW CIM300 Communication Interface Module (EIA-232/485),Discontinued

-

WATLOW MLS300-CIM Control Interface Module

-

WATLOW MLS300-AIM,Analog Input Module (16-channel expansion),Discontinued

-

WATLOW MLS300-PM Processor Module (Central CPU),Discontinued

-

Watlow MLS332 32-Loop Processor Base Unit,Discontinued

-

Watlow MLS316 Multi-loop thermal controller

-

Watlow CLS208 C10000CP high-performance, 8-loop PID temperature controller

-

Watlow CAS 16CLS/CAS Multi-loop temperature controller

-

ABB CP555 1SBP260179R1001 Product Overview

-

Watlow MLS300 Multi-Loop Control System

-

Watlow 997D-11CC-JURG SERIES 997 Vertical Limit Control

-

Watlow CLS216 Multi-Loop PID Temperature Controller

-

Watlow NLS300-CIM316 Multi-Loop Control Interface Module

-

Watlow PPC-TB50 (30280-00) Precision Power Controller

-

ABB 3BSE014227R1 RF533 Central Unit

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)