Woodward 723PLUS Digital Control

723PLUS Digital Control

9906-619. 9906-620. 9906-700

This manual describes the Woodward 723PLUS Digital Control hardware,

9906-619 (low voltage), 9906-620 (high voltage), and 9906-700 (modified

actuator filtering, low voltage).

Application

The 723PLUS Digital Control can be programmed to suit applications requiring

two magnetic pickups (MPUs) or proximity switches (e.g. for torsional filtering) as

the hardware includes two speed inputs. It also includes four analog inputs, three

analog outputs, eight discrete inputs and three discrete outputs, all of which can

be programmed to satisfy the application. The control can be used in load

sharing systems as it contains circuitry and connections to support this.

The two LON®* channels can be used to support Woodward LonTalk®* or

LinkNet® input/output nodes control functions.

*—LON and LonTalk are trademarks of Echelon Corporation.

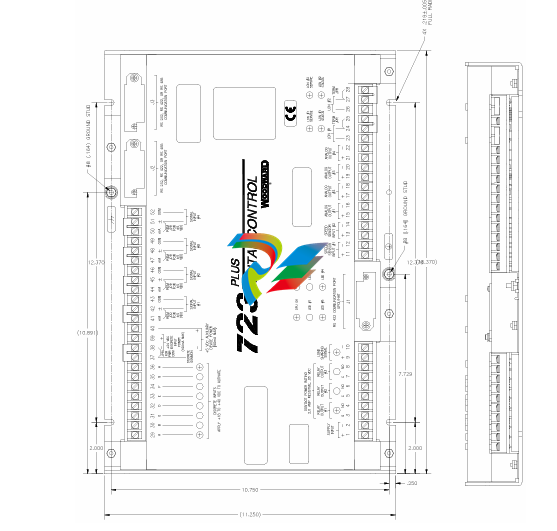

The 723PLUS control (Figure 1-1) consists of a single printed circuit board in a

sheet-metal chassis. Connections are via three terminal strips and three 9-pin

subminiature D connectors.

Control Options

The 723PLUS control requires the following power supply input voltages, with 40

watts as the nominal power consumption at rated voltage:

18–40 Vdc (24 or 32 Vdc nominal)

90–150 Vdc (125 Vdc nominal)

Discrete input voltages provide on/off command signals to the electronic control.

Each discrete input requires 10 mA at its 24 Vdc nominal voltage rating (for 24

volt switching logic).

Other control options are:

proximity switch input for speed signal frequencies below 100 Hz (see

NOTE)

0–1 mA for meter drivers

tandem actuator outputs

dual actuator outputs (0–200 mA)

The control may be used with either proximity switches (see NOTE) or magnetic

pickups. The minimum frequency for steady state speed control is 30 Hz. For

more information see Control Specifications (inside back cover).

723PLUS Digital Control Accessories

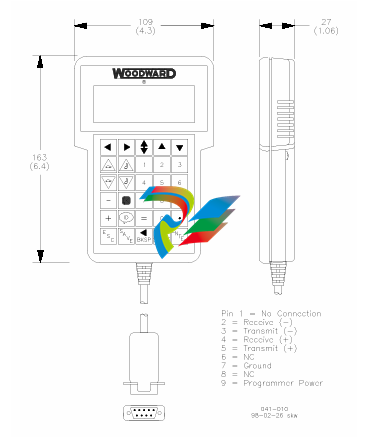

Hand Held Programmer (Figure 1-2), part number 9907-205. can be used

for adjusting the 723PLUS control. It plugs into serial port J1 of the control.

This part is EU Directive compliant.

SPM-A Synchronizer, for synchronizing the generator phase to that of the

power bus. The synchronizer generates a close generator breaker signal to

parallel the generator with the power bus.

Power Output Sensor, for load sharing or droop operation in mechanical

load applications.

Real Power Sensor, for load sharing or droop-parallel generator

applications.

Digital Synchronizer and Load Control (DSLC™) for generator load

management.

Rack Position Sensor, for mechanical load sharing.

Load Pulse Unit, for improved system load transient response.

LinkNet nodes for additional input/output control functions.

Scope

This chapter contains general installation instructions for the 723PLUS control.

Power requirements, environmental precautions, and location considerations are

included to help you determine the best location for the control. Additional

information includes unpacking instructions, electrical connections, and

installation checkout procedures.

Unpacking

Before handling the control, read page v, Electrostatic Discharge Awareness. Be

careful when unpacking the electronic control. Check the control for signs of

damage such as bent panels, scratches, and loose or broken parts. If any

damage is found, immediately notify the shipper.

Power Requirements

The high-voltage versions of the 723PLUS Digital Speed Control require a

voltage source of 90 to 150 Vdc. The low-voltage versions require a voltage

source of 18 to 40 Vdc

Location Considerations

Consider these requirements when selecting the mounting location:

adequate ventilation for cooling

space for servicing and repair

protection from direct exposure to water or to a condensation-prone

environment

protection from high-voltage or high-current devices, or devices which

produce electromagnetic interference in excess of levels defined in

EN50082–2

avoidance of vibration

selection of a location that will provide an operating temperature range of

40 to +70 °C (–40 to +158 °F)

Specific Marine Installation Requirements

Marine Type approval requirements change over time. In recent years, there has

been at least the addition of a stricter emission limit. A 156–165 MHz band notch

has been added and referred to here as the “Marine Notch”. To address the

Marine Notch, additional installation limitations are required for new installations

under the updated Marine Type approvals.

All wiring, except for the last 12 inches (305 mm) adjacent to the control

connection terminals must be inside a metal conduit, metal cable armoring,

enclosed metal cable way, or similar metal acting as a secondary shield. The

metal acting as the secondary shield must be grounded to the same reference

ground as the control chassis. In some cases, the chassis reference ground is

also referred to as Protective Earth (PE). All wiring must also follow the wiring

and shielding requirements given in the specific, separate software manual.

The control must be mounted on a metal mounting plate that is grounded to the

same reference ground potential as the control’s chassis.

Alternatively, if the installation is limited to areas of the ship where at least 6 dB

attenuation of the RF signals from the control can be guaranteed, no additional

special measures are needed. The signals in the 156–165 MHz range must be

attenuated by 6 dB before they reach the receiver antenna or receiver

(interference point), and the control must be >3 m away from the antenna or

receiver. This is a specific installation dependency, and some examples may

include:

A grounded, metal, IP rated cabinet with all cabling staying inside it for more

than 2 m length, with any shield terminations at the cabinet exit/entry point

and all unshielded cable routed directly against the metal cabinet.

A below-deck metal engine room where none of the cabling, including power,

leaves the engine room.

If using a specific installation location or method as a means to meet the Marine

Notch requirements, instead of a secondary metal shield for cabling, consult the

ship builder. Acceptability of the installation for obtaining 6 dB of RF attenuation

in the 156–165 MHz range must be provided by the ship builder. Woodward will

not know the ship installation application or requirements to provide guidance.

Internal Jumpers

The 723PLUS control has ten, two-position internal jumpers (JPR1 through

JPR20) located on the top of the printed circuit board. If it is necessary to change

any jumper to match your control requirements, and this suits the nature of the

software, be sure to read page v, Electrostatic Discharge Awareness.

Remove power and all inputs. Wait 45 seconds, then remove cover. With your

fingers or a small pair of tweezers, carefully remove the appropriate jumper and

replace it securely over the proper two connectors (see Figure 2-1).

Notes for Figure 2-2

Shielded wires are twisted pairs, with shield grounded at one end only. When

mounting control to bulkhead, use the grounding stud and hardware supplied with

the chassis to ensure proper grounding.

Shields must not be grounded at any external point unless otherwise noted.

All shields must be carried continuously through all terminal blocks and must not be

tied to other shields except at the common ground point. Tie all shields together at

ground stud located near connector J1.

Remove jumper for voltage input.

Remove jumper if using external discrete input power.

Discrete inputs are isolated from other circuits and intended to be powered by

TB1-39 (+24) leaving the jumper in place. Input current is nominally 10 mA input into

2210 Ω.

7. Unless otherwise specified:

A. Relays shown de-energized

B. Relays energize for function

C. Relay contact ratings for minimum 100 000 operations:

Resistive— 2.0 A at 28 Vdc

0.1 A at 115 Vac 50 to 400 Hz

Inductive— 0.75 A at 28 Vdc 0.2 Henry

0.1 A at 28 Vdc lamp

Analog output signals to other systems must be isolated from ground either by

design or employment of isolation amplifiers.

Analog input signals to other systems must be isolated from ground either by design

or employment of isolation amplifiers.

10. Factory set for MPU input.

11. Factory set for 20–160 mA output.

12. Factory set for 4–20 mA output.

13. Internal power supply provides dc isolation between the power source and all other

inputs and outputs.

14. Communication port J1 can be used with the Woodward ST2000 Hand Held

Programmer or PC Interface using Watch Window/Servlink software.

15. Communication port J2 or J3 can be configured as an RS-232. RS-422. or RS-485

serial interface. Port configuration can be done in the application software only. For

the pin assignment of J2 and J3. see later in this chapter.

16. This analog output may connect to a metering/controlling device. The shield should

be continuous between all connected devices with a single shield termination point to

ground.

17. Use twisted pair shielded wires only.

18. Remove jumper if used with the gas engine I/O node.

Termination is accomplished using a three-resistor voltage divider between a

positive voltage and ground. The impedance of the resistor network should be

equal to the characteristic impedance of the cable. This is usually about 100 to

120 ohms. The purpose is to maintain a voltage level between the two differential

lines so that the receiver will be in a stable condition. The differential voltage can

range between 0.2 and 6 volts; but the maximum voltage between either receiver

input and circuit ground must be less than 10 volts. There is one termination

resistor network for each port located on the 723PLUS board. Connection to this

resistor network is made through the 9-pin connectors on pins 6 and 9. See

Figures 2-5 through 2-8 for termination and cable connection examples.

Due to the variety of installations, plus system and component tolerances, the

723PLUS control must be tuned to each system for optimum performance.

This chapter contains information on how to enter control set points through the

control's menu system using the Hand Held Programmer. If you have access to

the Watch Window software tool and Servlink software, you can set up and tune

the 723PLUS control from a PC (personal computer) using the instructions in

Chapter 5 of this manual.

Hand Held Programmer and Menus

The Hand Held Programmer is a hand-held computer terminal that gets its power

from the 723PLUS control. The terminal connects to the RS-422 communication

serial port on the control (terminal J1). To connect the terminal, slightly loosen

the right-hand screw in the cover over J1 and rotate the cover clockwise to

expose the 9-pin connector. Then firmly seat the connector on the terminal into

J1.

The programmer does a power-up self-test whenever it is plugged into the

control. When the self-test is complete, the screen will display two lines of

information. This is information relating to the application. Pressing the ID key will

change the display to show the part number of the software and version letter.

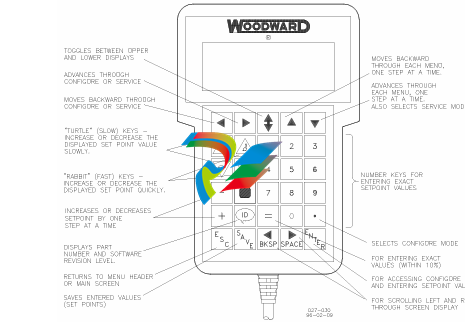

The programmer screen is a four-line, backlit LCD display. The display permits

you to look at two separate functions or menu items at the same time. Use the

UP/DOWN ARROW key to toggle between the two displayed items. The BKSP

and SPACE keys will scroll through the display to show the remainder of a

prompt if it is longer than the display screen's 18 characters.

The 723PLUS has two sets of menus—the Service menus and the Configure

menus. The Service menus allow easy access and tuning while the engine is

running. The Configure menus may be entered only if the I/O is shutdown (hence

the engine stopped).

Configure Menus

To access the Configure menus, the engine must be shut down. Press the key.

The display will show, “To select configure, press enter”. Press the ENTER key

and the display will show, “To shutdown I/O, press enter”. Press the ENTER key

and this will allow you into the Configure menus.

To move between the menus use the LEFT ARROW and RIGHT ARROW keys.

To move through the set points within a menu, use the UP ARROW and DOWN

ARROW keys. Once within a menu, to return to the menu header, press the ESC

key.

To leave the Configure menus press the ESC key. The set points will be

automatically saved when leaving Configure.

Service Menus

To access the Service menus press the DOWN ARROW key. To move between

menus, and to move through set points within menus follow the instructions as

for the Configure menus. Also to return to return to the menu header, or to leave

Service, follow the Configure instructions.

Adjusting Set Points

To adjust a set point, use the TURTLE UP or the RABBIT UP keys to increase

the value, and the TURTLE or RABBIT DOWN keys to decrease the value. The

RABBIT UP and RABBIT DOWN keys will make the rate of change faster than

the TURTLE UP and TURTLE DOWN keys. This is useful during initial setup

where a value may need to be changed significantly. Where necessary, to select

TRUE, use either the TURTLE UP or the RABBIT UP keys, and to select FALSE,

use the TURTLE DOWN or RABBIT DOWN keys.

Use the + or – keys to change integer values in the application software.

To obtain an exact value, press the = key. Key in the required figure and press

ENTER.

view the variables for your 723PLUS control on a PC (personal computer). These

instructions are meant to be introductory only. Full on-line help is available in

each application. It is assumed that you already have Servlink and Watch

Window installed. The default installation location can be found by clicking the

START icon (Microsoft Windows 95 or later) on the main menu bar and then

clicking the PROGRAMS menu item. Look for an icon called WOODWARD

WATCH WINDOW.

Make sure that all other programs that may access your computer

communications port are shut down.

Get the right cable to talk from your PC to the control (5416-614 will work for

J2 and J3. 5416-870 for J1).

Start the Servlink server and open a new file. Select the proper COM port for

your PC, verify that POINT TO POINT communications mode is selected,

and verify that the baud rate matches the baud rate of the 723PLUS. The

default baud rate is 19 200. See the on-line help file if you have been

changing the port settings of your control.

Select OK. If everything is working right, you should see an animated picture

of a string of “1”s and “0”s flying from the control to the PC on your screen.

You now have a network definition file whose default name is NET1. You

should save this file as “your filename.NET” (use FILE/SAVE AS). Link this

name to your control part number, as it will work only with that application.

For instance, if the upper level control number is 9907-031. you could save

the file as 9907031.NET. DO NOT DISCONNECT THE SERVER.

In the Servlink window you will now have another dialog window titled “your

filename.net”. In this window you will see a ballhead icon and a control

identifier name. Unless you have given the control a serial number (or name)

with the SLSN.EXE program, this name will display as “”.

Start the Watch Window application. When Watch Window executes, you will

have a screen displaying three windows entitled Watch Window, Explorer,

and Inspector.

The Explorer window will have two groups displayed, SERVICE and

CONFIGURE. Double clicking on either of these will expand them to show

groups of values. Explorer is used only to locate a tunable or monitor value.

In order to change a value or monitor a value, you must drag and drop a

value from the Explorer window into the Inspector window.

Once a value is displayed in the Inspector, you can see several blocks of

information. The most important blocks for a tunable value are the FIELD and

VALUE blocks. The FIELD block is used to identify a particular value, and the

VALUE block displays the current value of a variable. There are two types of

values available in Watch Window. One is a monitor value, which is marked

in the INSPECTOR window with a pair of glasses. This means it may only be

looked at. The other value is a read/write value, which is marked with a

pencil. The read/write type may be modified using the up and down arrows in

the value block.

Downloading to the 723PLUS

NOTE that this is the only way to download to a 723PLUS, and it will not work on

a regular 723.

Make sure that all other programs that may access your computer’s

communication port are shut down.

Get the right cable to talk from your PC to the control J1 port (5416-870).

Start the Servlink server and open a new file. From the dialog window, select

the proper COM port for your PC, select POINT TO POINT communications

mode, and set the baud rate to 19200.

Select OK. If everything is working right, you should see an animated picture

of a string of “1”s and “0”s flying from the control to the PC on your screen.

You now have a network definition file whose default name is NET1. You

should save this file. Link this name to your control part number as it will only

work with that application. For instance if the upper level control number is

9907-031. you could save the file as 9907031.NET. DO NOT DISCONNECT

THE SERVER.

In the Servlink window you will now have another dialog window titled “your

filename.net”. In this window you will see a ballhead icon and a control

identifier name. Unless you have given the control a serial number (or name)

with the SLSN.EXE program, this name will display as “”.

Start the Watch Window program. Under the title bar in the Explorer window

you will find a tab with your network file and the control ID displayed. Right

click this tab to display the pop-up menu, and select LOAD APPLICATION.

This will close the Inspector window and open a new window where you will

enter the name of the file you want to download. Once the filename is

correct, click on the OPEN button. A Warning screen will ask you to make

sure the engine is shut down before downloading. Downloading will proceed

automatically once your accept the message to shut down the engine.

Transferring Tunable Values Between 723PLUS

Controls

Note that this will not work with regular 723 controls.

Make sure that all other programs that may access your computer’s

communication port are shut down.

Get the right cable to talk from your PC to the control (5416-870 for J1. 5415-

614 for J2 or J3).

Start the Servlink server and open a new file. From the dialog window, select

the proper COM port for your PC, select POINT TO POINT communications

mode, and set the baud rate to 19200.

Select OK. If everything is working right, you should see an animated picture

of a string of “1”s and “0”s flying from the control to the PC on your screen.

You now have a network definition file whose default name is NET1. You

should save this file. Link this name to your control part number as it will only

work with that application. For instance if the upper level control number is

9907-031. you could save the file as 9907031.NET. DO NOT DISCONNECT

THE SERVER.

In the Servlink window you will now have another dialog window titled “your

filename.net”. In this window you will see a ballhead icon and a control

identifier name. Unless you have given the control a serial number (or name)

with the SLSN.EXE program, this name will display as “”.

Start the Watch Window program. Under the title bar in the Explorer window

you will find a tab with your network file and the control id displayed. Right

click this tab to display the pop-up menu, and select CONFIGURATION. If

you want to take the configuration from a control, select SAVE TO FILE. If

you want to download a new configuration to a control with an existing

application, then select LOAD FROM FILE.

If you select SAVE TO FILE, you will have to provide the name of a file

where you want to save the configuration. If your control has a part number

of 9907-031 then you might want to call this file 9907031.cfg. Make the name

meaningful so you can find it easily the next time you need it.

If you select LOAD FROM FILE you will get a confirmation warning telling

you that the unit will be shut down. If you answer yes then you will be asked

for the name of the configuration file that you want to download

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

-

ABB IGBT 5SDF0860H0003 5SDF1045H0002 unit

-

ABB TC512V1 3BSE018059R1 RS485 Twisted pair Modem

-

ABB DO880 S800HI 3BSE028602R1 Digital Output

-

ABB GDD360C 3BHE047217R0101 Advanced Automation Solution

-

ABB UCD240A101 3BHE022287R0101 controller unit

-

ABB AC800F Ethernet Module AM811F 3BDH000050R1

-

ABB AC800F Module AM801F 3BDH000040R1

-

ABB SD802F 3BDH000012R1 POWER UNIT

-

ABB operation panel PM820-2 3BSE010798R1 system module

-

ABB operation panel PM820-1 3BSE010797R1 system module

-

ABB CI857K01 3BSE018144R1 INSUM Ethernet Interface

-

ABB PM861/PM861AK01 and TP830 Processor Unit

-

ABB SA811F 3BDH000013R1 Power Supply 115/230 VAC

-

ABB 751010R0815 1VC1T0374A00R unit

-

5SGY35L4510 Robot high voltage board Brand ABB

-

ABB HVC-02B 3HNA024966-00103 Robot high voltage board Brand HVC02B

-

ABB SLMG99 UNIT

-

ABB 086406-002 PWA.SIOC. SMART I/O CALIP 086407-502

-

ABB UCD208A101 3BHE020018R0101 UNIT

-

ABB UAD154A 3BHE026866R0101 UNIT

-

ABB GCD207B101 3BHE024642R0101 controller card

-

ABB TB820V2 S800 Modulebus module 3BSE013208R1

-

ABB UDD406A 3BHE041465P201 Control unit

-

ABB PPD113B01-10-150000 3BHE023784R1023 unit CPU module

-

ABB 5SHY35L4512 3BHE014105R0001 5SXE08-0166 IGCT unit

-

ABB Backplane Uni Type3+housing FETD685A1156U01

-

ABB 07DC91C GJR5251400R0202 Digital input and output Unit

-

ABB UNS2881b-P,V1 3BHE009319R0001 UNS2881BPV1 Inspirational system

-

ABB UNS2880B-P,V2 3BHE014967R0002 UNS2880B-PV1 Inspirational system

-

ABB CI810B 3BSE020520R1 AF 100 Fieldbus Comm. Interface

-

ABB FM9925a-E HIEE451116R0001 Interface Module Card

-

Bently 2300/25 0002 Vibration Monitors

-

Bently 2300/20 0002 Vibration Monitors

-

ALSTOM VP327 020-23EU 75X-6025-29 Control mainboard VP32702

-

ABB NE802 3BSE080237R1 Industrial switch

-

ABB 3BSE080207R1 NE810 Industrial switch

-

MOTOROLA MVME2400 VME Processor Modules

-

ABB 3BHE021481R0001 intelligent current distr UNIT

-

MOTOROLA MVME2434 VME Processor Modules

-

METSO PDP606 CONTROLLER unit

-

WOODWARD PG-PL-29 Governor 8577-613

-

GE IS230TNRLH1B Combination module kit Mark VI

-

GE IS230TNAIH2C Combination module kit Mark VI

-

ABB 3ASC25H204 DAPU 100 Control board I/O

-

ABB 3BHE014070R0101 V PPC905AE101 CCB-2 COMPLETE

-

ABB PRC3BSE050198R1 PM866K01 Processor Unit

-

Kongsberg RAIV400 600370 Remote Analogue Input

-

ABB SPSED01 event sequence module

-

ABB HIEE300900R0001 PP C322 BE01 PSR-2 processor + fieldbus

-

ABB 3BHE003604R0102 UFC765AE102 circuit board

-

ABB ACU-01B 3HNA024871-001 Robot controller

-

ABB XVC770BE101 3BHE021083R0101 circuit board

-

ABB UAC383AE01 HIEE300890R0001 Module

-

ABB REF610C11LCNP FEEDER PROTECTION RELAY

-

ABB MT91 Operator Panel MT-91-ARC FP A

-

ABB XUD194 XUD194A 3BHC018137R0001 module base

-

ABB 5SHY4045L0001 3BHB018162 3BHE009681R0101 GVC750BE101

-

ABB G2000A5.7ST graphical operation panel (HMI)

-

ABB 3BHE017628R0002 PPD115A02 SG579989013

-

ABB Motor Protection and Control REM615 Product Guide

-

ABB PFTL101B 3BSE004185R1 2.0KN sensor

-

ABB PFCL201CE 50KN 3BSX802939-108 sensor

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)