abb Triguard SC300E 3BNP004720R101 TMR Safety Products

Triguard SC300E

The ABB Triguard SC300E is the

evolution of 20 years of combined

vendor and customer experience

integrated into the design of the

ultimate TMR product. Building on a

proven platform, the Triguard SC300E

combines features that will maintain

excellence well into the future.

Today ABB is a global supplier with

key operating bases in North America,

Europe, Middle East and Asia Pacific.

The Company has successfully

supplied TMR products and systems to

meet an ever increasing diverse range

of applications, including:

• Safety Shutdown

• Electrical Stability and Load Control

• Process Shutdown

• Reactor Control

• Emergency Shutdown

• Critical Batch Processing

• Sequence and Interlock Control

• Fire & Gas Protection and Detection

• Critical Process Control

• Burner Management and Control

• Turbine and Compressor Control

• Wellhead/Sub-Sea Control

• Unmanned Installations

• FPSOs

P r o d u c t F a m i l y

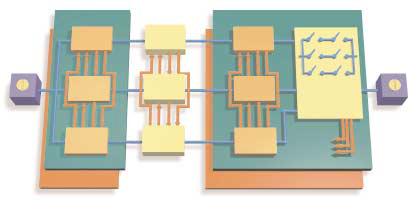

The ABB Triguard SC300E TMR product family gives unrivalled performance in areas of reliability, availability, test coverage,

diagnostics and simplicity of operation. Advances in technology and improved production methods add cost benefits that

give significant price/performance advantages.

• Fewer unscheduled stoppages

highest availability, fault tolerant electronics with transient immunity and 3–2–0 or 3–2–1–0 voting

• Security for plant, product and people

fail-safe operation at all levels provides plant, product and personnel with the highest security

• Quality data

sequence of event and extensive diagnostics keep the operator informed

Highest Availability

The Triguard SC300E achieves the

highest possible TMR availability

(99.999%) by maximising the

Mean Time To Failure (MTTF) and

decreasing the Mean Time To Repair

(MTTR).

Modern low power integrated

technology allows the TMR

architecture to be cost effective for

an increasing range of high integrity

applications.

Simple to Use, Operate

and Maintain

The Triguard SC300E TMR product

functions as a single set of hardware

and software. The three processors

and triplicated I/O circuitry are

transparent to the user. Purchasing a

Triguard SC300E system will provide:

• Lowest Life Cycle Cost

• The Maximum Safety and

Availability

• The Highest Level of Safety and

On-Line Maintenance

Fail Safe Operation

Failure modes of the processors,

input/output circuitry, control program

and watchdog timer circuits are

managed so that circuits will default to

a predetermined safe state.

Highest Speed of Response

By using advanced processor

technology, whilst maintaining the

stability of the original core software,

Triguard SC300E delivers an

unrivalled scan time resolution

of 10ms.

High speed of response benefits the

customer application which specifies

Sequence of Events recording (SoE)

without the cost of additional

equipment. It also enables TMR to be

used for applications requiring high

speed advanced control.

Fault Tolerant Hardware and

Software

The system is designed to continue to

operate correctly with the presence of

a major component fault and is

capable of tolerating multiple, non

concurrent faults.

Easy to Use Software –

WindowsTM

TriBuildTM configuration and

application programming and

TriCommandTM Server

(WONDERWARE© MMI interface

software) are WindowsTM compliant,

making the system easier to use for

the engineer and the operator. For

customers with existing ABB equipment

“backward compatibility” is provided

making upgrading or adding new

facilities economic to implement

TriBuildTM and TriCommandTM Server

can be used with Windows NTTM.

Features include:

• True multitasking capability

• Strategies can be saved on-line

without halting the system operation

• Ability to upload the configuration

• Changes can be made on-line

without halting the system operation

• Bumpless changeover of hot repair

modules

• Comprehensive diagnostic displays

for ease of maintenance

Fault Tolerance and

Selective Redundancy

Improvements in the system to keep a

process plant running safely without

the nuisance of false trips have been

achieved by full diagnostic coverage

of all modules and selective

redundancy.

Processors 3–2–1–0

Input/Output Circuits 3–2–1–0 or

3–2–0

Importance of Transient

Immunity

Comprehensive physical and electrical

isolation combined with asynchronous

processors and software voting

ensures the Triguard SC300E is

immune to transient errors.

Smallest Footprint Size

The Triguard SC300E TMR offers our

customers the best utilisation of

available space. ABB have developed

“plug and play” cabinet layout

configurations that offer pre-designed

hardware for system applications.

Plug and socketed system cables make

marshalling and termination

interconnection quick and easy to

implement.

Processor

Each Triguard SC300E TMR system

contains three processors. Each

processor operates asynchronously in

parallel with the other two processor

modules and receives power from the

redundant power supply units in the

main chassis. A triplicated bus system

on the chassis backplane connects

Key features of the processor modules:

• Intel processor

• Battery backed static RAM for

application logic

• RAM Battery backup supply for six

months

• 1 Mbyte of EPROM

• Real time clock for data logging to

10ms resolution

The Triguard SC300E has an operating

system known as the Real Time Task

Supervisor (RTTS), which is installed

in each of the three processors. The

operating system has been proven by

well over 10 million operational hours.

RTTS is transparent to the user, it

controls the off-line/start-up and

on-line continuous diagnostic and

voting functions, and provides a single

environment for the application

programming.

On power up, comprehensive

diagnostic routines check and validate

the correct operating parameters of

each processor.

The Triguard SC300E operating

system, RTTS, will permit the

processors to operate in a 3–2–1

format allowing a system to continue

to function with one healthy

processor. A replaced processor will

automatically acquire the data it

requires to become operational from

the on-line processor before going

on-line.

Input/Output Modules

All I/O module types share an

element of common design, providing

component rationalisation and

implementing distributed processing.

The three isolated TMR signal paths of

all input/output modules are

supervised by a micro-controllers

which:

• Provides fault isolation

• Co-ordinate signal processing

• Provides diagnostics

• Provides on-line to off-line

switching (hot repair)

• Provides data validation routines

• Provides data to the processor

• Provides latent fault detection

A fault in one signal path cannot be

passed to another. I/O modules can

be fitted in any of the 10 slots in any

chassis. “Hot Repair” is a customer

configurable option on a per module

basis. All modules are “keyed” to

prevent improper installation.

Digital Input Modules

The types of digital input modules

available are:

• 32 channel isolated

24Vdc120Vdc120Vac TMR

• 64 channel isolated 24Vdc Simplex

All TMR digital input modules are

100% triplicated to provide maximum

availability.

Each signal path conditions signals

independently and provides full

optical isolation between the field and

the SC300E. A fault on one signal path

cannot propagate to another.

Automatic latent fault testing will

detect “stuck on” states.

Line monitored inputs can be

implemented using analogue input

modules with line monitor termination

cards.

Digital Output Modules

The types of digital output modules

available are:

• 32 channel – supervised 24Vdc

TMR*

• 16 channel – supervised

120Vdc120Vac TMR*

All TMR digital output modules are

equipped with:

• Line monitoring circuits to confirm

energised field loop integrity

• Six element voting circuits for

maximum safety and availability

• Automatic latent fault testing and

diagnostics with 100% coverage (TMR)

Analogue Input Modules

The types of analogue input modules

available are:

• 32 channel isolated 0 to 5Vdc and 0

to 10Vdc TMR

(0 to 40mA and 0/4 to 20mA with

burden resistor at the termination

card)

Each analogue input signal path

contains three identical circuits of:

• Isolation

• Noise Filtering

• Multiplexing

• Amplification

• Analogue to digital conversion

and each of the three circuits is

supervised by a micro-controller.

The three circuits synchronously

measure the input signals, vote the

data and transmit the data to the

processors.

The processors condition the input

signal data, making any necessary

corrections, and then select the

mid-value from the three sets of input

data. This mid-value is then used by

the control program.

Analogue Output Modules

• 4 channel – 12 bit resolution

4–20mA TMR

Each of the three Triguard SC300E

processors sends voted output voltage

data to the analogue output modules.

The commands are received via

the bus system by the three

micro-controllers on each module

Pulse Input Analogue Output

Module (PIANO)

• 8 channel, 4 pulse input, 4 analogue

output TMR

The PIANO module contains fully

triplicated circuits. Each pulse input

path receives input pulses, a value

equivalent to the number of teeth on

a gear wheel for example, and

accumulates this data to an accuracy

of +_0.01% over 20Hz to 20KHz.

Output values to 12 bit resolution can

provide voted and validated data to

field devices for control (see analogue

output module for output circuit

operation).

Communications Module

A four channel serial communications

module is always fitted to a Triguard

SC300E TMR system to allow

communications to the engineering

workstation and is installed in I/O slot

number 10 of the main chassis. All

four channels operate RS232423 up

to 19.2 kbits/sec and all four

communication ports are fully isolated.

The four channel communications

module is directly addressed by the

three Triguard SC300E processors and

contains a micro-computer that

controls the four programmable

multi-protocol ports. Data received

from the three processors is voted

2oo3 providing correct data for

onward transmission.

High speed network

connectivity feature (to be

released)

Triguard may be interfaced to standard

communications networks such as

Ethernet/TCP/IP using approved

gateway products.

DCS connectivity includes:

• Yokogawa Electric, Elsag-Bailey,

Fisher Rosemount, ABB, Honeywell

and Foxboro

Hot Repair Facility

A quick repair procedure, once any

fault is revealed, is important in the

total fault tolerant product strategy.

The hot repair facility achieves a quick

and easy repair by the user and this is

done bumplessly without interrupting

the normal operation of the system

and process.

The operating system, RTTS, routinely

executes a hot repair task, checking

and validating that all configuration

data is correct, eg. correct I/O

module, on-line/off-line hot repair

functions.

All I/O modules can be programmed

for a hot repair facility. A wrong or

faulty module in an allocated hot

repair I/O slot will not be accepted.

Hot repair slots are selected to be

next to the system I/O resident

module.

There are three ways to replace an

on-line I/O module:

• Module with no additional hot

repair slot – single slot hot repair

• Module has an unpopulated hot

repair partner slot – manual hot

repair

• Module with a populated hot repair

partner slot – hot repair

Field Termination Cards

The types of termination cards

available:

• 16 channel – digital input

• 32 channel – digital input

• 16 channel – digital output

• 16 channel – analogue input

• 4 channel – analogue output

• 16 channel – digital output with line

monitoring

• 4 channel – pulse input

DIN rail mounted termination cards

for field wiring can be supplied as an

easy to fit method to route field cables

to the Triguard SC300E system I/O

modules, and distribute field wetting

current to each I/O point.

A termination card has an associated

system cable fitted with DIN

connectors to provide the plug and

socket arrangement. Cable lengths can

be specified to suit the application.

Alternative cables with Elco

connectors or free wires at the field

end are available for third party

marshalling systems.

Power and fusing for the field circuits

are standard. Options are available to

suit all field configurations.

System cables from the Triguard

SC300E are also available with free

wire ends so that the system may

connect to a separate cable

marshalling and power/fusing system.

Cabinet Layouts

Optional cabinets to house the

Triguard SC300E TMR control system

are industry standard 19” rack

mounted configurations with a width

of 600mm and a depth of 800mm. The

layouts shown are based on a standard

2000mm high cabinets, and provide

front and rear access. Front access

only configurations are available.

System Structure

A major benefit of the Triguard

SC300E system is that it can be as

small as one chassis or as large as 15,

giving a 9,500 total I/O capacity. The

TMR bus extender modules and cable

sets are used to size the system to suit

the application. Interfacing to remote

TMR I/O chassis or gateway modules

to connect to DCS networks, can

be provided to suit a combined

distributed safety and control strategy.

A customer who has a future

requirement to add to an existing

system will find the Triguard SC300E

easy and economical to extend.

Forward and backward compatibility

means that users can readily intermix

CS300 and Triguard SC300E systems

using the same programming tools.

Application logic written for a CS300

system will run with minimum

modification on the Triguard SC300E.

A fully distributed safety system,

using the Triguard SC300E, can be

configured by utilising a Safeway

8000 bus structure and the

Triguard peer to peer safety

approved protocol.

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

-

ABB IGBT 5SDF0860H0003 5SDF1045H0002 unit

-

ABB TC512V1 3BSE018059R1 RS485 Twisted pair Modem

-

ABB DO880 S800HI 3BSE028602R1 Digital Output

-

ABB GDD360C 3BHE047217R0101 Advanced Automation Solution

-

ABB UCD240A101 3BHE022287R0101 controller unit

-

ABB AC800F Ethernet Module AM811F 3BDH000050R1

-

ABB AC800F Module AM801F 3BDH000040R1

-

ABB SD802F 3BDH000012R1 POWER UNIT

-

ABB operation panel PM820-2 3BSE010798R1 system module

-

ABB operation panel PM820-1 3BSE010797R1 system module

-

ABB CI857K01 3BSE018144R1 INSUM Ethernet Interface

-

ABB PM861/PM861AK01 and TP830 Processor Unit

-

ABB SA811F 3BDH000013R1 Power Supply 115/230 VAC

-

ABB 751010R0815 1VC1T0374A00R unit

-

5SGY35L4510 Robot high voltage board Brand ABB

-

ABB HVC-02B 3HNA024966-00103 Robot high voltage board Brand HVC02B

-

ABB SLMG99 UNIT

-

ABB 086406-002 PWA.SIOC. SMART I/O CALIP 086407-502

-

ABB UCD208A101 3BHE020018R0101 UNIT

-

ABB UAD154A 3BHE026866R0101 UNIT

-

ABB GCD207B101 3BHE024642R0101 controller card

-

ABB TB820V2 S800 Modulebus module 3BSE013208R1

-

ABB UDD406A 3BHE041465P201 Control unit

-

ABB PPD113B01-10-150000 3BHE023784R1023 unit CPU module

-

ABB 5SHY35L4512 3BHE014105R0001 5SXE08-0166 IGCT unit

-

ABB Backplane Uni Type3+housing FETD685A1156U01

-

ABB 07DC91C GJR5251400R0202 Digital input and output Unit

-

ABB UNS2881b-P,V1 3BHE009319R0001 UNS2881BPV1 Inspirational system

-

ABB UNS2880B-P,V2 3BHE014967R0002 UNS2880B-PV1 Inspirational system

-

ABB CI810B 3BSE020520R1 AF 100 Fieldbus Comm. Interface

-

ABB FM9925a-E HIEE451116R0001 Interface Module Card

-

Bently 2300/25 0002 Vibration Monitors

-

Bently 2300/20 0002 Vibration Monitors

-

ALSTOM VP327 020-23EU 75X-6025-29 Control mainboard VP32702

-

ABB NE802 3BSE080237R1 Industrial switch

-

ABB 3BSE080207R1 NE810 Industrial switch

-

MOTOROLA MVME2400 VME Processor Modules

-

ABB 3BHE021481R0001 intelligent current distr UNIT

-

MOTOROLA MVME2434 VME Processor Modules

-

METSO PDP606 CONTROLLER unit

-

WOODWARD PG-PL-29 Governor 8577-613

-

GE IS230TNRLH1B Combination module kit Mark VI

-

GE IS230TNAIH2C Combination module kit Mark VI

-

ABB 3ASC25H204 DAPU 100 Control board I/O

-

ABB 3BHE014070R0101 V PPC905AE101 CCB-2 COMPLETE

-

ABB PRC3BSE050198R1 PM866K01 Processor Unit

-

Kongsberg RAIV400 600370 Remote Analogue Input

-

ABB SPSED01 event sequence module

-

ABB HIEE300900R0001 PP C322 BE01 PSR-2 processor + fieldbus

-

ABB 3BHE003604R0102 UFC765AE102 circuit board

-

ABB ACU-01B 3HNA024871-001 Robot controller

-

ABB XVC770BE101 3BHE021083R0101 circuit board

-

ABB UAC383AE01 HIEE300890R0001 Module

-

ABB REF610C11LCNP FEEDER PROTECTION RELAY

-

ABB MT91 Operator Panel MT-91-ARC FP A

-

ABB XUD194 XUD194A 3BHC018137R0001 module base

-

ABB 5SHY4045L0001 3BHB018162 3BHE009681R0101 GVC750BE101

-

ABB G2000A5.7ST graphical operation panel (HMI)

-

ABB 3BHE017628R0002 PPD115A02 SG579989013

-

ABB Motor Protection and Control REM615 Product Guide

-

ABB PFTL101B 3BSE004185R1 2.0KN sensor

-

ABB PFCL201CE 50KN 3BSX802939-108 sensor

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)