- LAND

- Pacific Scientific

- Kongsberg

- Abaco

- EMERSON

- NI

- LAMBDA

- Stucke Elektronik

- LEYBELOD

- AMAT

- ICS Triplex

- Lam Research

- KUKA

- Hirschmann

- ELAU

- EATON

- Applicom

- Watlow Anafaze

- Meggitt Vibro-meter

- Carrier

- Other

- ROCKWELL

- Rolls-Royce

- SAACKE

- Yokogawa

- B&R

- Reliance Electric

- Seifert

- A-B

- Weimeide Metso

- KEBA

- HIMatrix

- Valmet

- Schneider

- Prosoft

- PEPPERL+FUCHS

- Honeywell

- Woodward

- GE

- GEA Westfalia Separator

- Bently Nevada

- ALSTOM

- Foxboro

- MOTOROLA

- Fanuc

- VMIC

- KOLLMORGEN

- SEW

- Rexroth

- AEROTECH

- TOSHIBA

- TmeIC

- Sumitomo

- SOCAPEL SOCASIN

- SMC

- Stromag

- SIEMENS

- SCHUMACHER

- ABB

- MOOG

- EPRO

- EMERSON

- Triconex

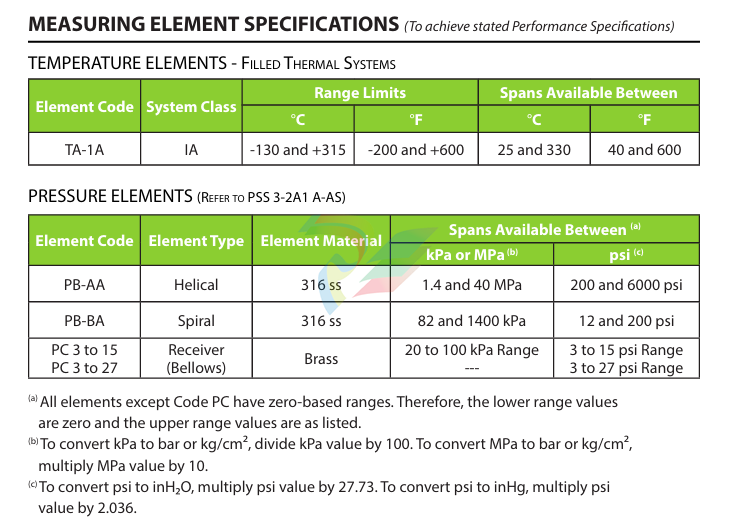

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

43AP-FA42D/PB-AA Foxboro 43AP Pneumatic Indicating Controllers

WIDE SELECTION OF MEASURING

ELEMENTS

Automation Service products offer a variety of

element constructions. This versatility enables

the 43AP Series Pneumatic Indicating Controllers

to be applied to virtually any process.

WIDE CHOICE OF CONTROL MODES

On-off, proportional, proportional plus

derivative, proportional plus integral (reset),

proportional plus integral plus derivative, and

differential gap actions are available.

BROAD RANGE OF INTEGRAL (RESET) AND

DERIVATIVE ADJUSTMENTS

The integral unit has the complete range from

0.01 to 50 minutes, and the derivative unit from

0.05 to 50 minutes.

VARIETY OF OPTIONS

These controllers are available with an extensive

list of optional features. Among these are

internal bumpless automatic-manual transfer

stations (two types), “batch” function, and remote

pneumatic set poin

ACCURACY UNAFFECTED BY MOUNTING

STRESSES

VERSATILE MOUNTING

Both the control unit and the measurement

element are mounted on a rigid steel plate. Thus,

these components are isolated from case stresses

due to mounting, and dependable accuracy is

ensured.

POWER FAILURES DO NOT INFLUENCE

PROCESS-DRIVEN INDICATION

A power failure and the likely subsequent loss

of supply pressure do not influence the process

driven indication.

WEATHERPROOF CONSTRUCTION

A glass fiber reinforced case and a gasketed

door with a shatterproof polycarbonate window

meet IEC IP53 and provide the environmental

protection of NEMA® Type 3.

Instruments may be mounted in a panel, on a

f

lat surface, on a continuous vertical pipe, or on a

vertical pipe stub.

INTERNAL BUMPLESS

AUTOMATIC-MANUAL TRANSFER STATION

This option provides bumpless-balanceable

transfer between automatic and manual control

by simple 2-step procedure. Accidental transfer

is avoided because the door must be opened to

gain access to the transfer station.

FUNCTIONAL SPECIFICATIONS

ELEMENTS

Refer to “Measuring Element Specifications” on

page 5 for types, materials, and ranges

CONTROLLER ACTION

Output signal either increases or decreases with

increasing measurement, as specified; action is

reversible in the field.

OUTPUT SIGNAL

20 to 100 kPa, 3 to 15 psi, or 0.2 to 1.0 bar or

kg/cm2. as specified.

AIR CONSUMPTION (UNDER NORMAL

OPERATION)

0.5 m3/h (0.3 cfm) at standard conditions

OUTPUT GAUGE

0 to 200 kPa, 0 to 30 psi, or 0 to 2 bar or kg/cm2.

as specified.

SET POINT ADJUSTMENT

By means of a knob mounted inside the case

POINTERS

Set point and measurement pointers are

f

luorescent red.

SCALE

Black markings on white background;

sector-shaped with nominal effective length of

150 mm (6 in).

CONNECTIONS

(Located in Bottom of Case)

PRESSURE AND VACUUM

• For upper range-values up to 14 MPa

(2000 psi, or 140 bar or kg/cm2):

Connections tapped for R1/4 or 1/4 NPT,

as specified.

• For upper range-values from 14 MPa

(2000 psi, or 140 bar or kg/cm2) up to

70 MPa (10.000 psi, or 700 bar or

kg/cm2): Connections threaded for R1/2

or 1/2 NPT, as specified.

• For upper range-values above 70 MPa

(10 000 psi, or 700 bar or kg/cm2):

9/16-18 Aminco® fitting used.

PNEUMATIC

• Supply and output connections tapped

for 1/4 NPT.

MOUNTING

PANEL

• Flush in a panel up to 16 mm (0.6 in) thick.

SURFACE

• Suitable for all controllers having

internally mounted elements.

PIPE

• A kit of parts to fit a DN 50 or 2 in vertical

pipe

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

-

Woodward ESDR 4 Current Differential Protection Relay

-

Woodward easYgen-3000 Genset Control for

-

Woodward CPC-II Current-to-Pressure Converter

-

Woodward 8290-189-EPG-installation-manual 8290-044

-

Woodward Product Change Notification 06946A

-

Woodward Product Change Notification 06912

-

Fisher™ 4660 High-Low Pressure Pilot

-

Flexible digital protection and control equipment SYMAP®

-

Woodward 723PLUS Digital Control

-

Woodward 505 Digital Controller For steam turbineses

-

Woodward 85018V2 505E Digital Governor for Extraction Steam Turbines

-

Woodward 85018V1 Turbine Control Parameters

-

Woodward 26871 505 Enhanced Digital Control for Steam Turbines

-

Woodward 03365 505E (Extraction / Admission)

-

KONGSBERG RMP420-Remote Multipurpose Input/Output

-

KONGSBERG RCU501 Remote Controller Unit

-

KONGSBERG RCU500 Remote Controller Unit

-

K-Gauge TOP KONGSBERG Tank Overfill Protection SystemFeatures

-

Kongsberg DPS112 DGNSS (DGPS/DGLONASS) sensor

-

Kongsberg d0000930 presafe-atex-report signed

-

HIMax TECHNICAL FACTS X Series

-

GE Multilin F650

-

GE MIF II - Legacy

-

GE PQM II Power QualIty Meter

-

Hydran 201Ti Mark IV Essential DGA monitoring for transformers

-

alstom AMS42/84 5B Amplifier SystemAmplifier Technology at its Best.

-

GE VMIVME-5576 Fiber-Optic Reflective Memory with Interrupts

-

GE Multilin 750/760 - Legacy Feeder Protection System

-

GE Fanuc Automation VMICPCI-7806 Specifications

-

GE VMIVME-7807 VME-7807RC* Intel® Pentium® M-Based VME SBC

-

GE Fanuc Automation VMIVME-7750 Specifications

-

FOXBORO Compact FBM240. Redundant with Readback, Discrete

-

FOXBORO FBM208/b, Redundant with Readback, 0 to 20 mA I/O Module

-

FOXBORO FBM201e Analog Input (0 to 20 mA) Interface Modules

-

Foxboro DCS FBM206 Pulse Input Module

-

FOXBORO FBM216 HART® Communication Redundant Input Interface Module

-

FOXBORO Z-Module Control Processor 270 (ZCP270)

-

Foxboro DCS Compact FBM241/c/d, Redundant, Discrete I/O Modules

-

Foxboro FBM223 PROFIBUS-DP™ Communication Interface Module

-

Foxboro DCS FBM204. 0 to 20 mAI/OModule

-

Foxboro FBM239, Discrete 16DI/16DO Module

-

Foxboro FBM202 Thermocouple/mV Input Module

-

Foxboro E69F Current-to-Pneumatic Signal Converter

-

EMERSON M-series Intrinsically Safe I/O

-

Configuration for AMS 6500 Protection Monitors

-

EMERSON DeltaV™ M-series Traditional I/O

-

EMERSON DeltaV™ SQ Controller

-

AEROTECH Ndrive MP Hardware Manual

-

AEROTECH Ndrive HPe 10/20/30

-

AEROTECH Ndrive CP Hardware Manual

-

AEROTECH Ndrive Linear Series Digital Servo Amplifiers – Linear

-

AEROTECH Ndrive HP 10/20/30 P/N: EDU170

-

AEROTECH EDU176_Ndrive_HL

-

ADVANCEDMOTION CONTROLS Analog Servo Drive 120A10

-

GE JPAX-H

-

GE JPAX family

-

GE Industry Leading Experience

-

GE Ether-1000 Unit

-

GE Cyber Secured Service Unit

-

GE Lentronics E1MXe Multiplexer

-

GE TTMX Teleprotection Terminal

-

GE Lentronics T1 Multiplexer

-

GE Lentronics JungleMUX SONET Multiplexer

-

GE Lentronics E1MX Multiplexer

-

GE Lentronics TN1Ue SDH Multiplexer

-

GE Lentronics TN1U SDH Multiplexer

-

GE Gridcom DXC Family Access and Transmission Multiplexer

-

GE Advanced Network Management

-

GE Lentronics VistaNET Network Management System (NMS)

-

ABB System Controller Connect

-

Ethernet Module EI 803F ABB

-

ABB Ethernet Modules EI 802F

-

ABB Ethernet Modules EI 801F

-

ABB Power Supply SD 802F / SD 812F

-

ABB Power Supply SA 801F / SA 811F

-

ABB Basic Unit PM 802F /PM 803F

-

Control product - Soft starter PST/PSTB (Intelligent Type) ABB

-

ABB CP450 Installation and Operation Manual

-

ABB ompact 800 5.1 Product Catalog

-

ABB Panel 800 version 6

-

ABB Panel 800 Version 6- Panel Builder Version 6.0-1

-

ABB Control Panels CP405 Control Panels CP408

-

ABB PowerUP for medium voltage drives

-

GE MiCOM P40U Connect MiCOM P40 IEDs to PCs with USB ports

-

Reason RT431 GPS Precision-Time Clock GE

-

GE Reason RT430 GNSS Precision-Time Clocks

-

GE Reason H49 PRP/HSR Redbox Switch

-

GE Reason S20 Managed Ethernet Switches

-

GE Gridcom DIP.net

-

Central Control Station at Jaenschwalde mineLausitzer Braunkohle AG, Germany 2000

-

ABB Ability™ System 800xA Advant® Master S400 I/O to S800 I/O Evolution

-

ABB with Advant Controller 400 series

-

Advant™Automation with MOD 300™ Software

-

Bently 2300/20 and 2300/25 2300 Vibration Monitors

-

ABB NGC8206 Natural Gas Chromatograph Dual Unit

-

MOTOROLA MVME2400 TM VME Processor Modules

-

5320 Series Foxboro DCS Control Network Ethernet Equipment

-

ExtremeSwitching™ 5420 Series

-

WOODWARD EGCP-3 Engine Generator Control Package LS (Load Sharing)

-

5520 Series Universal Edge/Aggregation-Switch Platform

-

X440-G2 Series

-

EMERSON FloBoss™ S600 Flow Manager Specification Sheet

-

KONGSBERG RAIV400 Remote Analogue Input, Voltage

-

RMP420-Remote Multipurpose Input/Output Kongsberg

-

610 serie ABB Feeder Protection REF610 Product Guide

-

Triconex 3351S2 Controller Features

-

HBRF Megamax – Emax2 Air Circuit Breaker ABB

-

ABB MEASUREMENT & ANALYTICS | DATA SHEET LS4000 Diode laser analyzer

-

Pressductor Pillowblock Load Cells Vertical Measuring PFCL 201 User manual

-

PARKER BFR5K Series

-

AC 900F controller ABB

-

Uniop ePAD05 and ePAD06 Technical description

-

Hitachi ABB Communication Unit 560CMR02

-

MOTOROLA MVME5500 Series VME Single-Board Computer

-

ABB Symphony Plus SD Series HPC800 controller

-

ABB AC800M Controller Hardware System

-

ABB AC800M PROFIBUS DP Installation System

-

ABB Freelance 800F AC800F Control systems

-

ABB Compact control system replaces PLC AC700F

-

abb Triguard SC300E 3BNP004720R101 TMR Safety Products

-

ABB Distributed busbar protection REB500

-

ABB Advant Controller 400 series

-

ABB MEASUREMENT & ANALYTICS | PRODUCT GUIDE

-

PACIFIC SCIENTIFIC PC800 PC832 PC830 Series Digital Brushless Servo Drive

-

PSS41S-3FDCTSAA Triconex DCS System Access Application Driver for Field Device Controller 280

-

Alstom controller of ICP232 029.359325

-

DEIF DU-2/MKIII Paralleling And Protection Unit General information

-

ABB 3ADT220134R0001 SDCS-COM-81 board 10MBd

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)