- LAND

- Pacific Scientific

- Kongsberg

- Abaco

- EMERSON

- NI

- LAMBDA

- Stucke Elektronik

- LEYBELOD

- AMAT

- ICS Triplex

- Lam Research

- KUKA

- Hirschmann

- ELAU

- EATON

- Applicom

- Watlow Anafaze

- Meggitt Vibro-meter

- Carrier

- Other

- ROCKWELL

- Rolls-Royce

- SAACKE

- Yokogawa

- B&R

- Reliance Electric

- Seifert

- A-B

- Weimeide Metso

- KEBA

- HIMatrix

- Valmet

- Schneider

- Prosoft

- PEPPERL+FUCHS

- Honeywell

- Woodward

- GE

- GEA Westfalia Separator

- Bently Nevada

- ALSTOM

- Foxboro

- MOTOROLA

- Fanuc

- VMIC

- KOLLMORGEN

- SEW

- Rexroth

- AEROTECH

- TOSHIBA

- TmeIC

- Sumitomo

- SOCAPEL SOCASIN

- SMC

- Stromag

- SIEMENS

- SCHUMACHER

- ABB

- MOOG

- EPRO

- EMERSON

- Triconex

ABB PFCL201CE 50KN 3BSX802939-108 sensor

Measuring principle of the sensor

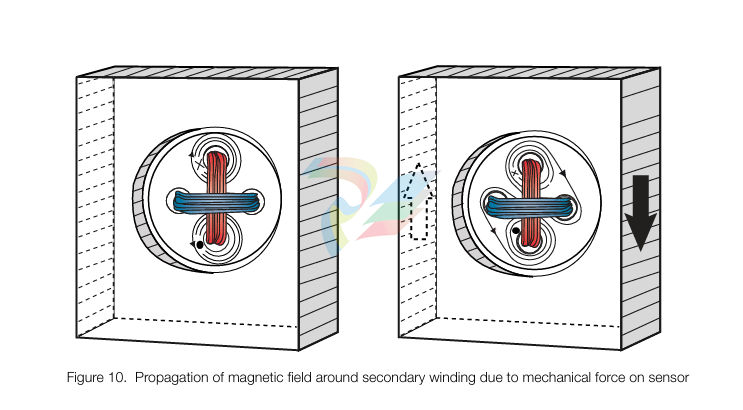

The measuring principle of the sensor is based on the Pressductor® technology and the fact that the permeability of a magnetic material changes under mechanical stress.

The sensor is a membrane machined in the load cell. Primary and secondary windings are wound through four holes in the load cell so that they cross at right angles.

The primary winding is supplied with an alternating current which creates a magnetic field around the primary winding. Since the two windings are at right angles to each other, there will be no mag netic field around the secondary winding, as long as there is no load on the sensor.

When the sensor is subjected to a mechanical force in the direction of measurement, the propaga tion of the magnetic field changes so that it surrounds the secondary winding, inducing an alternat ing voltage in that winding.

The control unit converts this alternating voltage into a DC voltage proportional to the applied force. If the measurement force changes direction, the sensor signal changes also polarity.

Mounting Arrangement

When choosing a mounting arrangement it is important to remember to position the load cell in a

direction that gives sufficient measuring force (FR) to achieve the highest possible accuracy.

The load cell has no particular correct orientation; it is positioned in the orientation best suited for

the application, bearing in mind the positions of the screw holes. The load cell can also be installed

with the roll suspended under the load cell.

The load cell has the same sensitivity in both tension and compression, so the load cell can be

installed in the easiest manner.

Typical mounting arrangements are horizontal and inclined mounting.

Coordinate System

A coordinate system is defined for the load cell. This is used in force calculations to derive force

components in the load cell principal directions.

Where direction designations R, V and A are recognized as suffixes for force components, F, this represents the force component in the respective direction. The suffix R may be omitted, when measuring direction is implied by the context.

Horizontal Mounting In the majority of cases horizontal mounting is the most obvious and simplest solution. Stand, mounting surface and shims (if required) are simple and cheap to make. When calculating the force, the equations below must be used: FR = T × (sin α + sin β) FRT = Tare FRtot = FR + FRT = T × (sin α + sin β) + Tare FV = T × (cos β - cos α) FVT = 0 FVtot = FV + FVT = T × (cos β - cos α) + 0 = T × (cos β - cos α) where: T = Strip tension FR = Force component from strip tension in measurement direction, R FRT = Force component from Tare in measurement direction, R FRtot = Total force in measurement direction, R FV = Force component from strip tension in transverse direction, V FVT = Force component from Tare in transverse direction, V FVtot = Total force in transverse direction, V Tare = Force due to tare weight α = Deflection angle on one side of the roll relative the horizontal plane β = Deflection angle on the other side of the roll relative the horizontal plane

Inclined Mounting

Inclined mounting means arrangements in which the load cell is inclined relative to the horizontal

plane. In some cases this is the only option.

When calculating the force, the equations below must be used:

FR = T × [sin (α - γ) + sin (β + γ)] FRT = Tare × cos γ FRtot = FR + FRT = T × [sin (α - γ) + sin (β + γ)] + Tare × cos γ FV = T × [cos (β + γ) - cos (α - γ)] FVT = - Tare × sin γ FVtot = FV + FVT = T × [cos (β + γ) - cos (α - γ)] - Tare × sin γ γ = 90° - φ where: T = Strip tension FR = Force component from strip tension in measurement direction, R FRT = Force component from Tare in measurement direction, R FRtot = Total force in measurement direction, R FV = Force component from strip tension in transverse direction, V FVT = Force component from Tare in transverse direction, V FVtot = Total force in transverse direction, V Tare = Force due to tare weight α = Deflection angle on one side of the roll relative the horizontal plane β = Deflection angle on the other side of the roll relative the horizontal plane φ= Angle for measurement direction relative the horizontal plane γ = Angle for load cell mounting surface relative the horizontal plane

The Electrical Circuit

The electrical circuit of the load cell is shown in the diagram below.

The load cell is supplied with a 0.5 A, 330 Hz alternating current. The secondary signal is calibrated for the correct sensitivity with a voltage divider R1 - R2, and temperature compensation is provided by thermistors T.

All impedances on the secondary side are relatively low. The output impedance is typically 9-12 Ω , which helps to suppress interference.

ABB UDC920BE01 3BHE034863R0001

ABB XUD194 XUD194A 3BHC018137R0001

ABB PPD513AOC-100440 3BHE039724R0C3D 800 D513

ABB 5SHY4045L0001 3BHB018162 3BHE009681R0101 GVC750BE101

ABB 3BHE039724R0C3D PPD513 A0C-100440 AC800PEC

ABB DKTFM418B 3BHB015651P0001

ABB G2000A5.7ST

ABB 3BHE017628R0002 PPD115A02 SG579989013

ABB REM615 HBMBCCAHNBA1ANN1XD

ABB LS4000

ABB PM864AK01 3BSE01816R1

ABB PFTL101B 3BSE004185R1 2.0KN

ABB PFCL201CE 50KN 3BSX802939-108

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

-

Woodward ESDR 4 Current Differential Protection Relay

-

Woodward easYgen-3000 Genset Control for

-

Woodward CPC-II Current-to-Pressure Converter

-

Woodward 8290-189-EPG-installation-manual 8290-044

-

Woodward Product Change Notification 06946A

-

Woodward Product Change Notification 06912

-

Fisher™ 4660 High-Low Pressure Pilot

-

Flexible digital protection and control equipment SYMAP®

-

Woodward 723PLUS Digital Control

-

Woodward 505 Digital Controller For steam turbineses

-

Woodward 85018V2 505E Digital Governor for Extraction Steam Turbines

-

Woodward 85018V1 Turbine Control Parameters

-

Woodward 26871 505 Enhanced Digital Control for Steam Turbines

-

Woodward 03365 505E (Extraction / Admission)

-

KONGSBERG RMP420-Remote Multipurpose Input/Output

-

KONGSBERG RCU501 Remote Controller Unit

-

KONGSBERG RCU500 Remote Controller Unit

-

K-Gauge TOP KONGSBERG Tank Overfill Protection SystemFeatures

-

Kongsberg DPS112 DGNSS (DGPS/DGLONASS) sensor

-

Kongsberg d0000930 presafe-atex-report signed

-

HIMax TECHNICAL FACTS X Series

-

GE Multilin F650

-

GE MIF II - Legacy

-

GE PQM II Power QualIty Meter

-

Hydran 201Ti Mark IV Essential DGA monitoring for transformers

-

alstom AMS42/84 5B Amplifier SystemAmplifier Technology at its Best.

-

GE VMIVME-5576 Fiber-Optic Reflective Memory with Interrupts

-

GE Multilin 750/760 - Legacy Feeder Protection System

-

GE Fanuc Automation VMICPCI-7806 Specifications

-

GE VMIVME-7807 VME-7807RC* Intel® Pentium® M-Based VME SBC

-

GE Fanuc Automation VMIVME-7750 Specifications

-

FOXBORO Compact FBM240. Redundant with Readback, Discrete

-

FOXBORO FBM208/b, Redundant with Readback, 0 to 20 mA I/O Module

-

FOXBORO FBM201e Analog Input (0 to 20 mA) Interface Modules

-

Foxboro DCS FBM206 Pulse Input Module

-

FOXBORO FBM216 HART® Communication Redundant Input Interface Module

-

FOXBORO Z-Module Control Processor 270 (ZCP270)

-

Foxboro DCS Compact FBM241/c/d, Redundant, Discrete I/O Modules

-

Foxboro FBM223 PROFIBUS-DP™ Communication Interface Module

-

Foxboro DCS FBM204. 0 to 20 mAI/OModule

-

Foxboro FBM239, Discrete 16DI/16DO Module

-

Foxboro FBM202 Thermocouple/mV Input Module

-

Foxboro E69F Current-to-Pneumatic Signal Converter

-

EMERSON M-series Intrinsically Safe I/O

-

Configuration for AMS 6500 Protection Monitors

-

EMERSON DeltaV™ M-series Traditional I/O

-

EMERSON DeltaV™ SQ Controller

-

AEROTECH Ndrive MP Hardware Manual

-

AEROTECH Ndrive HPe 10/20/30

-

AEROTECH Ndrive CP Hardware Manual

-

AEROTECH Ndrive Linear Series Digital Servo Amplifiers – Linear

-

AEROTECH Ndrive HP 10/20/30 P/N: EDU170

-

AEROTECH EDU176_Ndrive_HL

-

ADVANCEDMOTION CONTROLS Analog Servo Drive 120A10

-

GE JPAX-H

-

GE JPAX family

-

GE Industry Leading Experience

-

GE Ether-1000 Unit

-

GE Cyber Secured Service Unit

-

GE Lentronics E1MXe Multiplexer

-

GE TTMX Teleprotection Terminal

-

GE Lentronics T1 Multiplexer

-

GE Lentronics JungleMUX SONET Multiplexer

-

GE Lentronics E1MX Multiplexer

-

GE Lentronics TN1Ue SDH Multiplexer

-

GE Lentronics TN1U SDH Multiplexer

-

GE Gridcom DXC Family Access and Transmission Multiplexer

-

GE Advanced Network Management

-

GE Lentronics VistaNET Network Management System (NMS)

-

ABB System Controller Connect

-

Ethernet Module EI 803F ABB

-

ABB Ethernet Modules EI 802F

-

ABB Ethernet Modules EI 801F

-

ABB Power Supply SD 802F / SD 812F

-

ABB Power Supply SA 801F / SA 811F

-

ABB Basic Unit PM 802F /PM 803F

-

Control product - Soft starter PST/PSTB (Intelligent Type) ABB

-

ABB CP450 Installation and Operation Manual

-

ABB ompact 800 5.1 Product Catalog

-

ABB Panel 800 version 6

-

ABB Panel 800 Version 6- Panel Builder Version 6.0-1

-

ABB Control Panels CP405 Control Panels CP408

-

ABB PowerUP for medium voltage drives

-

GE MiCOM P40U Connect MiCOM P40 IEDs to PCs with USB ports

-

Reason RT431 GPS Precision-Time Clock GE

-

GE Reason RT430 GNSS Precision-Time Clocks

-

GE Reason H49 PRP/HSR Redbox Switch

-

GE Reason S20 Managed Ethernet Switches

-

GE Gridcom DIP.net

-

Central Control Station at Jaenschwalde mineLausitzer Braunkohle AG, Germany 2000

-

ABB Ability™ System 800xA Advant® Master S400 I/O to S800 I/O Evolution

-

ABB with Advant Controller 400 series

-

Advant™Automation with MOD 300™ Software

-

Bently 2300/20 and 2300/25 2300 Vibration Monitors

-

ABB NGC8206 Natural Gas Chromatograph Dual Unit

-

MOTOROLA MVME2400 TM VME Processor Modules

-

5320 Series Foxboro DCS Control Network Ethernet Equipment

-

ExtremeSwitching™ 5420 Series

-

WOODWARD EGCP-3 Engine Generator Control Package LS (Load Sharing)

-

5520 Series Universal Edge/Aggregation-Switch Platform

-

X440-G2 Series

-

EMERSON FloBoss™ S600 Flow Manager Specification Sheet

-

KONGSBERG RAIV400 Remote Analogue Input, Voltage

-

RMP420-Remote Multipurpose Input/Output Kongsberg

-

610 serie ABB Feeder Protection REF610 Product Guide

-

Triconex 3351S2 Controller Features

-

HBRF Megamax – Emax2 Air Circuit Breaker ABB

-

ABB MEASUREMENT & ANALYTICS | DATA SHEET LS4000 Diode laser analyzer

-

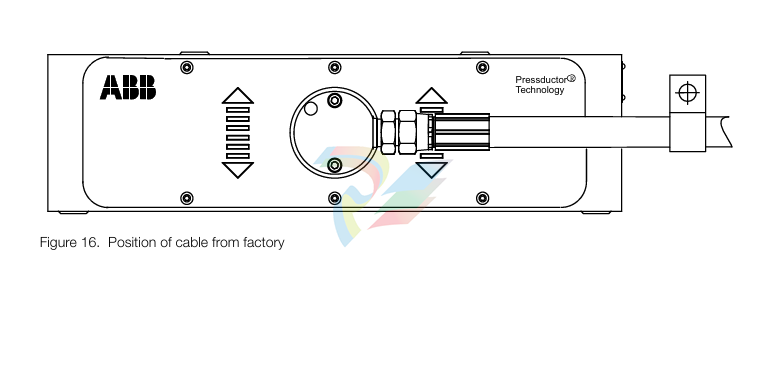

Pressductor Pillowblock Load Cells Vertical Measuring PFCL 201 User manual

-

PARKER BFR5K Series

-

AC 900F controller ABB

-

Uniop ePAD05 and ePAD06 Technical description

-

Hitachi ABB Communication Unit 560CMR02

-

MOTOROLA MVME5500 Series VME Single-Board Computer

-

ABB Symphony Plus SD Series HPC800 controller

-

ABB AC800M Controller Hardware System

-

ABB AC800M PROFIBUS DP Installation System

-

ABB Freelance 800F AC800F Control systems

-

ABB Compact control system replaces PLC AC700F

-

abb Triguard SC300E 3BNP004720R101 TMR Safety Products

-

ABB Distributed busbar protection REB500

-

ABB Advant Controller 400 series

-

ABB MEASUREMENT & ANALYTICS | PRODUCT GUIDE

-

PACIFIC SCIENTIFIC PC800 PC832 PC830 Series Digital Brushless Servo Drive

-

PSS41S-3FDCTSAA Triconex DCS System Access Application Driver for Field Device Controller 280

-

Alstom controller of ICP232 029.359325

-

DEIF DU-2/MKIII Paralleling And Protection Unit General information

-

ABB 3ADT220134R0001 SDCS-COM-81 board 10MBd

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)