EMERSON Part Number D301150X412 FloBoss™ S600+ Flow Computer Instruction Manual

FloBoss S600+ Flow Computer

The FloBoss S600+ Flow Computer is a panel-mounted (for indooruse)

flow computer designed specifically to measure hydrocarbon

liquid and gas where versatility and accuracy matter. The standard

features of the S600+ make it ideal for fiscal measurement, custody

transfer, batch loading, and meter proving applications. The S600+

allows you to configure multi-stream, multi-station applications,

enabling you to simultaneously meter liquids and gasses.

The S600+ is designed for use either as a stand-alone flow computer or

as a system component. The intelligent I/O modules fit both gas and

liquid applications and typically support two dual-pulsed streams and a

header. Adding I/O modules (up to a maximum of three) allows you to configure up to six dual-pulsed streams or up to 10 single-pulsed streams and two headers. The S600+ supports orifice, ultrasonic, turbine, positive displacement, Coriolis, Annubar, and V-Cone® flow meter types and master meter, small volume compact, and pipe (both bi-directional and uni-directional) proving methods.

The S600+ offers a variety of communication interfaces:

Two LAN ports (on the enhanced CPU module) for Ethernet 10Base-T or 100Base-T full-duplex connectivity (using either Modbus TCP or Modbus over Ethernet protocols).

Note: The Ethernet module (P190), which provided an additional Ethernet port for previous versions of the S600, is not compatible with the S600+.

HART® communication using up to two 12-channel HART modules, each of which supports point-to-point and multi-drop architectures for up to 50 transmitters.

Note: The FloBoss S600+ is fully compatible with HART 5 devices, and HART 7 devices are backwards compatible with HART 5 devices.

An embedded webserver allows remote access to the flow computer. Security is provided using user name and password protection with a detailed event log for audit purposes (supports Microsoft® Edge™ or Windows® Internet Explorer® version 5 or greater [version 9 or greater must use compatibility mode]).

Two configurable RS-232 serial ports.

Three RS-422/RS-485 serial ports (supporting up to 57,600 bps baud) and up to four RS-485 2-wire serial ports (supporting up to 57,600 baud rate) for connection to intelligent meters, Modbus SCADA data networks, DCS supervisory systems, and so on.

One dedicated configuration port (located on the bottom of front display panel) for connection to the Config 600 configuration software.

Additional communications interfaces include:

• Serial Q.Sonic®

• Serial printer

• Serial or Modbus TCP Daniel chromatograph via Modbus

• Serial peer-to-peer

• Modbus EFM protocol, Modbus RTU, Modbus ASCII, Modbus over Ethernet, and Modbus TCP

Miscellaneous interfaces which can operate via serial or Modbus TCP:

Daniel liquid ultrasonic

Daniel gas ultrasonic

Sick ultrasonic Daniel chromatograph

Note: All ports can connect to DCS systems, ultrasonic meters, Coriolis meters, and so on.

The S600+ uses distributed processing to achieve maximum performance. The CPU module incorporates a hardware floating point processor. Each additional module also has local processing to convert inputs and output from engineering units to field values and vice-versa, as well as running background tests and PID loops.

The firmware uses 64-bit (double) precision floating point numbers for the highest accuracy when performing all metering calculations. Cumulative totals are stored in three separate memory locations (Tri-reg format) for maximum integrity. The user language LogiCalc™ also allows you to perform logical control and double-precision mathematical functions on the database objects.

Front Display Panel

The S600+’s front panel interface enables you to manage an existing configuration or create a configuration using the PC-based Config 600 configuration software.

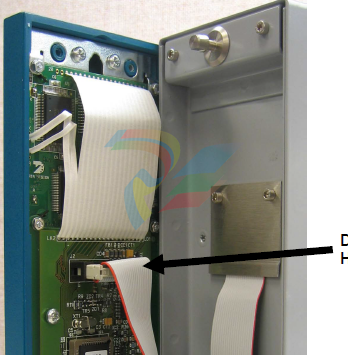

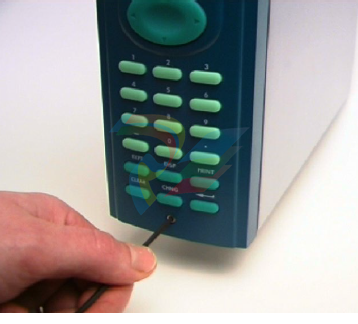

A communications port on the bottom of the panel provides a way to directly connect to a PC. The front panel interface consists of a backlit LCD display, a 29-button keypad, and an alarm status LED (see Figure 1-4).

Config600 Configuration Software

Using Config 600, you can both send (upload) new or modified configurations to the S600+ and receive (download) existing

configurations from the S600+. You can also define the following functions:

Stream and station totalisation.

Batch totalisation and correction.

Three-term PID control.

Flow balancing.

Flow scheduling.

Automatic proving sequence.

K-factor or meter factor linearisation.

Valve monitor/control.

Sampler control.

Station densitometer.

Station gas chromatograph.

Forward, reverse, and premium error totals.

Comprehensive maintenance mode.

Reporting.

Modbus.

Modify display matrix.

Config600 is a suite of software editors that enables you to monitor, configure, and calibrate the S600+. The software comes in three versions – Config600 Lite, Config600 Lite Plus, and Config600 Pro – with Config600 Pro being the most powerful version.

Note: The S600+ does not operate until you send a configuration to it from the host PC.

IPL600

Remote Automation Solutions provides a separate utility program called “Interactive Program Loader 600” (or “IPL600”).

Using IPL600 and an IP or a dedicated serial port connection between a host PC and an S600+, you can transfer and receive configuration files (reports, Modbus configurations, customised displays, and LogiCalc programs). While included as the Config Transfer utility in Config600, IPL600 has a standalone use for situations when you do not need the full functionality of Config600. Details on using Config Transfer/IPL600 are provided in the Config600 Software User Manual (Part D301220X412).

1.3.1 Config600 Lite

Use the Config 600 Lite software editor suite to modify pre-developed configurations, transfer existing configurations, edit items on the front panel display, and customise reports.

Note: You typically use Config600 Lite to custom-configure a new S600+ during installation.

With Config600 Lite you can:

Edit process configuration data, including orifice size, analog input scaling, alarm limits, and keypad values.

Build and customise Modbus slave maps, Modbus master polling sequences, front panel displays, and period report formats.

Customise the alarm system, including alarm groups, suppression, and inhibits.

Configure system security by setting user names and passwords, and assigning access levels for each data object on the displays.

Specify the engineering units and totalisation rollover value.

Reflash the CPU module firmware with software upgrades and transfer configurations via the Config Transfer utility (IPL600).

Config600 Lite Plus

The Config600 Lite Plus software editor suite provides all the functionality of the Config600 Lite suite, but adds the ability to create a configuration file.

With Config600 Lite Plus you can:

Create a new application from base templates for gas, liquid, and prover applications.

Edit process configuration data, including orifice size, analog input scaling, alarm limits, and keypad values.

Build and customise Modbus slave maps, Modbus master polling sequences, front panel displays, and period report formats.

Customise the alarm system, including alarm groups, suppression, and inhibits.

Configure system security by setting user names and passwords, and assigning access levels for each data object on the displays.

Specify the engineering units and totalisation rollover value.

Reflash the CPU module firmware with software upgrades and transfer configurations via the Config Transfer utility (IPL600).

Config600 Pro

configurations, modify existing configurations, transfer existing configurations, edit items on the front panel display, and edit custom reports.

With Config600 Pro you can:

Create a new application from base templates for gas, liquid, and prover applications.

Edit process configuration data, including orifice size, analog input scaling, alarm limits, and keypad values.

Build and customise Modbus slave maps, Modbus master polling sequences, front panel displays, and period report formats.

Specify the engineering units and totalisation rollover value.

Customise the alarm system, including alarm groups, suppression,

text, and inhibits.

Configure system security by setting user names and passwords,

and assigning access levels for each data object.

Add and remove objects from the database.

Program special features using LogiCalc.

Reflash the CPU module firmware with software upgrades and

transfer configurations via the Config Transfer utility (IPL600).

Additional Technical Information

Refer to the following technical documents (available at

www.Emerson.com/EnergyandTransportation) for additional and

most-current information.

Table 1-1. Related Technical Information

Name Form Number Part Number

FloBoss™ S600+ Flow Computer S600+ D301151X412

Config600™ Configuration Software Config600 D301164X012

Config600™ Configuration Software User Manual A6169 D301220X412

Preparing for Installation

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

-

ABB IGBT 5SDF0860H0003 5SDF1045H0002 unit

-

ABB TC512V1 3BSE018059R1 RS485 Twisted pair Modem

-

ABB DO880 S800HI 3BSE028602R1 Digital Output

-

ABB GDD360C 3BHE047217R0101 Advanced Automation Solution

-

ABB UCD240A101 3BHE022287R0101 controller unit

-

ABB AC800F Ethernet Module AM811F 3BDH000050R1

-

ABB AC800F Module AM801F 3BDH000040R1

-

ABB SD802F 3BDH000012R1 POWER UNIT

-

ABB operation panel PM820-2 3BSE010798R1 system module

-

ABB operation panel PM820-1 3BSE010797R1 system module

-

ABB CI857K01 3BSE018144R1 INSUM Ethernet Interface

-

ABB PM861/PM861AK01 and TP830 Processor Unit

-

ABB SA811F 3BDH000013R1 Power Supply 115/230 VAC

-

ABB 751010R0815 1VC1T0374A00R unit

-

5SGY35L4510 Robot high voltage board Brand ABB

-

ABB HVC-02B 3HNA024966-00103 Robot high voltage board Brand HVC02B

-

ABB SLMG99 UNIT

-

ABB 086406-002 PWA.SIOC. SMART I/O CALIP 086407-502

-

ABB UCD208A101 3BHE020018R0101 UNIT

-

ABB UAD154A 3BHE026866R0101 UNIT

-

ABB GCD207B101 3BHE024642R0101 controller card

-

ABB TB820V2 S800 Modulebus module 3BSE013208R1

-

ABB UDD406A 3BHE041465P201 Control unit

-

ABB PPD113B01-10-150000 3BHE023784R1023 unit CPU module

-

ABB 5SHY35L4512 3BHE014105R0001 5SXE08-0166 IGCT unit

-

ABB Backplane Uni Type3+housing FETD685A1156U01

-

ABB 07DC91C GJR5251400R0202 Digital input and output Unit

-

ABB UNS2881b-P,V1 3BHE009319R0001 UNS2881BPV1 Inspirational system

-

ABB UNS2880B-P,V2 3BHE014967R0002 UNS2880B-PV1 Inspirational system

-

ABB CI810B 3BSE020520R1 AF 100 Fieldbus Comm. Interface

-

ABB FM9925a-E HIEE451116R0001 Interface Module Card

-

Bently 2300/25 0002 Vibration Monitors

-

Bently 2300/20 0002 Vibration Monitors

-

ALSTOM VP327 020-23EU 75X-6025-29 Control mainboard VP32702

-

ABB NE802 3BSE080237R1 Industrial switch

-

ABB 3BSE080207R1 NE810 Industrial switch

-

MOTOROLA MVME2400 VME Processor Modules

-

ABB 3BHE021481R0001 intelligent current distr UNIT

-

MOTOROLA MVME2434 VME Processor Modules

-

METSO PDP606 CONTROLLER unit

-

WOODWARD PG-PL-29 Governor 8577-613

-

GE IS230TNRLH1B Combination module kit Mark VI

-

GE IS230TNAIH2C Combination module kit Mark VI

-

ABB 3ASC25H204 DAPU 100 Control board I/O

-

ABB 3BHE014070R0101 V PPC905AE101 CCB-2 COMPLETE

-

ABB PRC3BSE050198R1 PM866K01 Processor Unit

-

Kongsberg RAIV400 600370 Remote Analogue Input

-

ABB SPSED01 event sequence module

-

ABB HIEE300900R0001 PP C322 BE01 PSR-2 processor + fieldbus

-

ABB 3BHE003604R0102 UFC765AE102 circuit board

-

ABB ACU-01B 3HNA024871-001 Robot controller

-

ABB XVC770BE101 3BHE021083R0101 circuit board

-

ABB UAC383AE01 HIEE300890R0001 Module

-

ABB REF610C11LCNP FEEDER PROTECTION RELAY

-

ABB MT91 Operator Panel MT-91-ARC FP A

-

ABB XUD194 XUD194A 3BHC018137R0001 module base

-

ABB 5SHY4045L0001 3BHB018162 3BHE009681R0101 GVC750BE101

-

ABB G2000A5.7ST graphical operation panel (HMI)

-

ABB 3BHE017628R0002 PPD115A02 SG579989013

-

ABB Motor Protection and Control REM615 Product Guide

-

ABB PFTL101B 3BSE004185R1 2.0KN sensor

-

ABB PFCL201CE 50KN 3BSX802939-108 sensor

-

ABB 3BHE023784R2530 PPD113B01-25-111000 AC 800PEC

-

ABB 3BHE046836R0101 GF D563 A101 LCI Conv. Interface (LIN)

-

ABB PPD512A10-454000 3BHE040375R103E PPD512 丨AC800PEC

-

ABB PPD117A3011 3BHE030410R3011 excitation controller

-

ABB AC800M PM891 3BSE053240R1 Processor module

-

ABB PP882 3BSE069275R1 HMI operating touch screen

-

ABB HIEE205014R0001 UNC 4673A,V1 Analog Measuring Card

-

ABB 128057-204 ASPC ASSY, W/-004

-

ABB 3BHB006716R0277 SYN 5302a-Z,V277: Auto dual channel Syn

-

ABB PFSK 163 V3 3BSE016323R3 Module

-

ABB 3BUS208796-001 HKQCS PARTS ON LINE

-

ABB 2VAA008425R1 RMU610 Base for redundant cRBX01

-

ABB 3BSE018876R1 PFSK 151 DSP-Signal processing

-

Westinghouse 1C31129G03 1C31129G01, 1B30035H01 Ovation analog output module

-

Pacific scientific PC833-001-N-BA communication module

-

HONEYWELL 30733159-002 supplied by Honeywell

-

BENTLY 3500/94M 184826-01 VGA Display Monitor

-

BENTLY 1900/65A 172323-01General Purpose Equipment

-

Bently Nevada 9200-01-01-10-00 Speed Sensor

-

Bently Nevada 330104-00-05-10-02-00 Proximity detector

-

Bently Nevada 330901-05-32-05-02-00 3300 XL NSv proximity sensor

-

Bently Nevada ASSY78462-01U I/O module recording terminal

-

330901-00-90-05-02-00 Bently Nevada3300 NSv Proximity Probes

-

330180-X1-CN Bently Nevada Proximity sensor

-

Bently Nevada 3500/92 136188-01 RS232 communication gateway module

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)