GE 369 MOTOR PROTECTION SySTEM KEy BENEFITS

Integrated protection and control for medium sized AC motors

• Enhanced Thermal Model including RTD and Current Unbalance Biasing

• Complete Asset monitoring with programmable RTD inputs for Stator, Bearing and Ambient temperature protection

• Enhanced reporting - Motor Health Reports provide critical information for preventative maintenance

• Reduce troubleshooting time and maintenance costs -Event reports, waveform capture, motor start data logger

• Multiple communication protocols - Modbus RTU, Profibus, DeviceNet, Modbus TCP/IP

• Simplified programming with the EnerVistaTM 369 Motor Settings Auto-Configurator

• Optional Conformal coating for exposure to chemically corrosive or humid environments (option)

• Field upgradable settings and firmware

• Suitable for hazardous locations - UL certification for Class 1 Division 2 applications (option MOD502)

• Installation flexibility - Remote display and remote RTD options

• Safe and reliable motor re-start on “Down Hole” pump applications - Unique back spin detection feature detects flow reversal on a pump motor, enabling timely and safe motor restarting

• User definable parameters and data size for DeviceNet polling

• User definable parameters and data size for Profibus DPV1 cyclic data

• Motor learned data on historical start characteristics

APPLICATIONS

• Protection and control for medium sized AC motors

• “Down Hole” pump applications

• Suitable for applications involving Variable Frequency Drives

• Two Speed motor application

FEATURES

Protection and Control • Enhanced thermal model • Stall / Jam protection • Undervoltage, overvoltage • Underfrequency • Thermal overload • Undercurrent/current unbalance • Variable lockout time • Overtemperature 12 RTDs (R option) • Starts/hour, time between starts • Voltage Phase Reversal (M option) • Current based phase reversal • Undervoltage Auto-restart

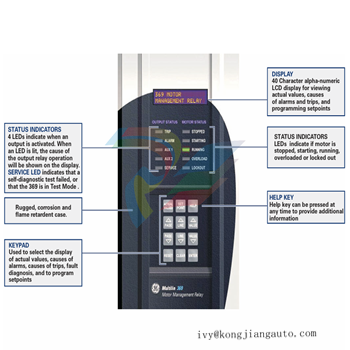

User Interface • 40 Character LCD Display • 10 System and Motor Status LED’s • Keypad for configuration and viewing metered values • 4 programmable analog outputs • 369 Motor Settings Auto-Configurator

Monitoring and Metering • Metering - current, voltage, power, energy, frequency, RTD Temperature, Remote RTD • Fault diagnosis, - Event Record, Oscillography, Motor Starting Data Logger • Motor Health Report • Statistical information & learned motor data • Voltage/frequency/power display (M option) • 4 analog outputs (M option)

Communications • Front Panel RS232 port for programming and troubleshooting • Optional embedded Ethernet port • Optional Profibus DP/DPV1 or DeviceNet via dedicated port • Multiple Protocols - Modbus RTU, Modbus TCP/IP

EnerVistaTM Software • State of the art software for configuration and commissioning GE Multilin products • Document and software archiving toolset to ensure reference material and device utilities are up-to-date • EnerVistaTM Integrator providing easy integration of data in the 369 into new or existing monitoring and control systems

Protection & Control

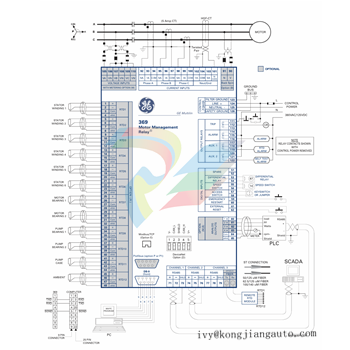

The 369 is a digital motor protection system designed to protect and manage medium sized AC motors and their driven equipment. It contains a full range of selectively enabled, self contained protection and control elements as detailed in the Functional Block Diagram and Features table.

Motor Thermal Model The primary protective function of the 369 is the thermal model with six key elements: • Overload Curves • Unbalance Biasing • Hot/Cold Safe Stall Ratio • Motor Cooling Time Constants • Start Inhibit and Emergency Restart • RTD Biasing

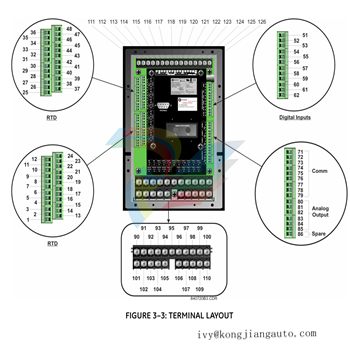

Inputs and Outputs

The 369 features a variety of digital input and output channels. Any of the

programmable digital inputs may be selected and programmed as a separate General Switch, Digital Counter, or Waveform Capture Input. In addition the programmable digital inputs may be selected and programmed to perform one of the following functions: Emergency Restart, Differential Switch, Speed Switch, or Remote Reset as described below

GE 369-HI-R-0-0-0-0-E

GE 369-HI-R-M-F-E-H-E

GE EP-3124

GE EP-5261

GE 369-HI-R-M-0-0-0-E

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

-

UniOP ECT-16-0045 High-Performance Color Touchscreen HMI

-

UniOP ERT-16 - Industrial PLC Workstation

-

UniOP ePAD04-0046 Compact Industrial Interface

-

UniOP BKDR-16 High-Reliability Monochrome Operator Interface

-

UniOP MKDR-04-004 Control Unit Panel

-

UniOP eTOP515 Series 500 HMI

-

Woodward 9907-1199 Advanced CPC-II Current-to-Pressure Converter

-

Woodward 8200-1300 High-Precision 505D Steam Turbine Controller

-

ABB PFSK130 3BSE002616R1 Core Signal Conditioning Unit

-

ABB PFSK165 3BSE027778R1 VP74201-933CW07 Signal Processing and Communication Unit

-

ABB PFSK164 3BSE021180R1 Tension sensor module and processing board

-

ABB 3BSE006505R1 PFSK142 Control board

-

ABB PFSK160A 3BSE009514R1 Regulated High-Capacity 24V DC

-

ABB PFSK162 3BSE015088R1 Signal Conditioning and Processing Board

-

ABB PFSK152 3BSE018877R1 Signal concentrator board

-

ABB PFSK151 3BSE018876R1 High-performance signal processing unit

-

ALSTOM PIB1201A 3BEC0067 Power Interface Board (PIB)

-

ALSTOM PIB310 3BHB0190 Adapter Module / Printed Circuit Board (PCB)

-

ALSTOM PIB102A 3BEB0180 Communication Card / PCB Module

-

ALSTOM BGTR8HE 24491276A1004 High-Frequency Power Controller / Rack Module

-

ALSTOM LC105A-1 Digital Discrete Output (Relay)

-

ALSTOM IR139-1 High-Efficiency Inverter / Control Board

-

ALSTOM AM164 Analog Output / Remote I/O

-

ALSTOM LE109A-1 Power System Control and Monitoring Module

-

ALSTOM UT150-1 PID temperature controller / process control board

-

ALSTOM AL132 AL132A STO0982E01 Control Motherboard / CPU Card

-

ALSTOM AS111-1 Analog Output (AO) Module

-

WATLOW AH116-2 Servo Drive / Control Module

-

WATLOW V4555724-0100 Electromechanical Contactor /Power Switch

-

Alstom KCEU142 Digital Protection Relay

-

ALSTOM MMLG01 Test block

-

WATLOW 999D,999A Digital/Analog Dual-Channel Base Unit

-

WATLOW 998D 998A Digital/Analog Dual-Channel Base Unit

-

WATLOW 999D-11FF-AARG Dual-channel digital unit with universal process outputs

-

WATLOW Wattlo 998D-22KK-ARRG is a high-performance dual-channel digital controller

-

WATLOW 996A Single-loop controller

-

WATLOW 996D-11CC-CUGR Single-loop digital controller

-

WATLOW 996D Single-Channel Digital Temperature/Process Controller

-

WATLOW 997D Digital Dual-Channel Base Unit

-

WATLOW 997A Analog Dual-Channel Variant

-

WATLOW DAC / SDAC Digital-to-Analog / Serial-to-Analog Modules

-

WATLOW MLS300-OIT Operator Interface Terminal (Keypad/Display),Discontinued

-

WATLOW CIM300 Communication Interface Module (EIA-232/485),Discontinued

-

WATLOW MLS300-CIM Control Interface Module

-

WATLOW MLS300-AIM,Analog Input Module (16-channel expansion),Discontinued

-

WATLOW MLS300-PM Processor Module (Central CPU),Discontinued

-

Watlow MLS332 32-Loop Processor Base Unit,Discontinued

-

Watlow MLS316 Multi-loop thermal controller

-

Watlow CLS208 C10000CP high-performance, 8-loop PID temperature controller

-

Watlow CAS 16CLS/CAS Multi-loop temperature controller

-

ABB CP555 1SBP260179R1001 Product Overview

-

Watlow MLS300 Multi-Loop Control System

-

Watlow 997D-11CC-JURG SERIES 997 Vertical Limit Control

-

Watlow CLS216 Multi-Loop PID Temperature Controller

-

Watlow NLS300-CIM316 Multi-Loop Control Interface Module

-

Watlow PPC-TB50 (30280-00) Precision Power Controller

-

ABB 3BSE014227R1 RF533 Central Unit

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)