AC 800PEC series PVD164A2059 3BHE014340R2059 high performance control system.

AC 800PEC series PVD164A2059 3BHE014340R2059 high performance control system.

AC 800PECHigh performance control systemFor high power rectifier applications

High performance application with extremely fast control algorithm–The cycle time range of fast control is 100 μs (microseconds).Cycle to seconds for long-term operating transients-requirementsSpecial control equipment.This is why we designed AC 800PEC, which extends ABB's famous automation technology to deal with the algorithm application program of high-speed power electronics and other processes. Can you imagine a process loop, a moment below 100 μs? We can-we invented a new generation of AC 800PEC controllers to accomplish it. Dual-core processor unit combines these high-speed manipulation and low-speed processing, which makes the technology further manipulated. The task is usually performed by an independent PLC (programmable logic controller) unit. Embedded in the robust and sensitive architecture, the integrated standard communication AC 800PEC is unique in the field of industrial process controllers. AC 800PEC is the ultimate product close to high requirements. AC 800PEC has the following unique combination characteristics for severe application: short cycle time, as low as 100 μs high processing, fast communication and I/O programming can be completed through optical fiber links:-The system engineering conforming to IEC61131-3 uses the words of ABB to control the generator. Two languages-compact and professional version-product and control development uses MATLAB /Simulink based on model design, which easily bridges the gap from simulation to performance, and is completely integrated into ABB Ability system. 800xA uses FPGAs creatively and sensitively, and the protocols and application functions contained in it do not need to create rated processors. The life cycle of optical communication is longer than that of industrial-grade hardware without moving parts, and it is easy to upgrade to a strong reliance file system, which is not affected by post.

ABB has global expertise and know-how to use programs in industrial, marine and other processes. Therefore, AC 800PEC is a key controller used by ABB industry, and it is also suitable for third-party products and systems. AC 800PEC is an efficient and flexible manipulator series. Advantages of short cycle time, fast input/output, High processing ability and advanced control using MATLAB /Simulink: improve process quality and output, save development and engineering cost, reduce the time to market of your energy-consuming products, save engineering personnel and resources, and improve software development. The modular structure system of input/output AC 800PEC controller integrated with ROA and fast means that it can be used to any size, from the largest factory and propulsion system to very compact products, in which space and cost are of paramount importance. Thousands of processors all over the world are proving their value in all kinds of extremely demanding uses.The function and power are adjusted, and the high-efficiency and high-speed strong hardware processing AC 800PEC combines the flexibility and high-speed ability of the floating-point CPU accounting function FPGA. The system is divided into three levels with different functions covering different cycle times. The allocation of control missions depends on their speed requirements: ultra-fast mission FPGA mission as low as 25 nanoseconds) fast mission as low as 100 microseconds) The hardware architecture of slowing down the mission to 1 millisecond (millisecond control mission) AC 800PEC is a perfect match with the three-layer software structure. In order to support short processing cycle time, AC 800PEC provides a fast I/O system. According to the speed of I/O connection, the data throughput may be less than 100 μs, including reading, processing, writing and transmitting signals

ABB has global expertise and know-how to use programs in industrial, marine and other processes. Therefore, AC 800PEC is a key controller used by ABB industry, and it is also suitable for third-party products and systems. AC 800PEC is an efficient and flexible manipulator series. Advantages of short cycle time, fast input/output, High processing ability and advanced control using MATLAB /Simulink: improve process quality and output, save development and engineering cost, reduce the time to market of your energy-consuming products, save engineering personnel and resources, and improve software development. The modular structure system of input/output AC 800PEC controller integrated with ROA and fast means that it can be used to any size, from the largest factory and propulsion system to very compact products, in which space and cost are of paramount importance. Thousands of processors all over the world are proving their value in all kinds of extremely demanding uses.

AC 800PEC software provides a special range of control and communication functions at three performance levels. We have developed the following software packages to support the rectifier application of each of our specific high-power products. Aluminum uses the AC 800PEC equipment controller. The AC 800PEC main controller communicates with the controller through PEC-PEC optical fiber. The optical link (100 μs) can be mastered independently of the control unit to allow urgent operation (full smooth current control, in urgent mode, there is no AC 800 PEC, Only used in combination with DCS800 pre-magnetization) software that can contain predictive maintenance functions such as open circuit, overcurrent, undervoltage and overvoltage maintenance package-newly developed OPC (open circuit maintenance) independent PLC (programmable logic controller), controlled shutdown in maintenance events with AC 800PEC main controller function or independent maintenance panel as main equipment, You don't need to travel immediately → reduce the disturbance to you. Potline load swing detection and load shedding application software integrates the function of on-load tap changer quick tapping function. In order to avoid DC current overload disturbing the special potentiometer based on AC 800PEC series, the maximum power can be adjusted (permed)-to avoid excessive power consumption, and support your generator to adjust your process with stable maximum DC voltage.

Electric arc furnace uses stable arc detection and different control forms (constant current, stable power or stable resistance) to quickly connect to PQS electrode for adjustment; The functions of anode hydraulic system control include: manual electrode control (analog or digital), rapid electrode improvement function (with or without independent rapid rising valve), active arc ignition function, active arc reignition function, adaptive electrode control behavior according to the furnace or voltage fluctuation measurement (stability index calculation) of thermal stage superposition integral control circuit, arc to roof detection/ Maintenance of arc to roof maintenance order during arc flashover hydraulic oil pressure monitoring and electrode maintenance collapse exploration high pressure detection back pressure valve control logic voltage to ground monitoring roof voltage monitoring electrode active lifting function instruction (optional distance or orientation) blocking valve control electrode and electrode speed limit arm maintenance future function-active proportional valve linearization check-active proportional valve linearization-stable dynamic voltage set point control melting processElectric arc furnace uses stable arc detection and different control forms (constant current, stable power or stable resistance) to quickly connect to PQS electrode for adjustment; The functions of anode hydraulic system control include: manual electrode control (analog or digital), rapid electrode improvement function (with or without independent rapid rising valve), active arc ignition function, active arc reignition function, adaptive electrode control behavior according to the furnace or voltage fluctuation measurement (stability index calculation) of thermal stage superposition integral control circuit, arc to roof detection/ Maintenance of arc to roof maintenance order during arc flashover hydraulic oil pressure monitoring and electrode maintenance collapse exploration high pressure detection back pressure valve control logic voltage to ground monitoring roof voltage monitoring electrode active lifting function instruction (optional distance or orientation) blocking valve control electrode and electrode speed limit arm maintenance future function-active proportional valve linearization check-active proportional valve linearization-stable dynamic voltage set point control melting process

Chemical use: OLTC step compensation control in lubrication process-IDC step compensation of lubrication current and current change during boosting. OLTC power factor compensation can include predictive maintenance function. Software maintenance package includes:-DC over-current maintenance-communication over-voltage and under-voltage maintenance-communication phase imbalance maintenance -12-pulse system imbalance maintenance system. DC grounding fault detection can be realized by 3-volt meter with SIL 3-level process pulse. The voltage at the input of the module loop crosses the voltage sag. Electrolytic extraction industry (copper and zinc): IDC current step compensation, which is used for the current change during lubrication and boosting. The power factor compensation of OLTC can include predictive maintenance functions: DC overcurrent maintenance, communication overvoltage and undervoltage maintenance, communication phase imbalance maintenance, 12-pulse system imbalance maintenance system, main DC current control unit of parallel rectifier, DC open-loop detection during operation, DC open-loop maintenance, and the graphitization process of DC power supply in graphite electrode factory requires a lot of DC voltage and current change power supply. Providing a constant DC power supply to the process does not take into account the changing process resistance-probably due to the very fast cycle time AC 800PEC controller. Ability to add customized process recipes and modify them in order on the operation panel to meet specific customer requirements. After adding the corresponding formula, the rectifier follows the predefined DC current, DC voltage and maximum allowable power set point, including all necessary chart-specific maintenance functions.

Function scalability: You and your process define what you need, and your process defines the required function level. Several pre-equipped software packages can easily obtain simple projects. The processing cycle time of distributed control system is as low as 1 millisecond. Using slow I/O to program man-machine interface in control generator is as low as 1 millisecond. Using interface programming in slow and fast I/O control generator to support almost all common fieldbus hardware time stamps can be provided to programmable logic controller as low as 1 millisecond on request. Using fast and slow I/ O programming in the control generator, the programmable automation controller cycle time is as low as 100 μs, fast and slow I/O MATLAB /Simulink programming and any speed process interface AC 800PEC of the control generator supply two types of I/O-fast, and it is very slow. The fast I/O system includes the time when reading and writing operations need less than 1 ms, while the slow I/O system covers the speed of more than 1 millisecond. The fast I/O system is dedicated to AC 800PEC, which uses equipment connected only by optical fiber links, and has obvious advantages compared with the electric concept: the fast communication I/O equipment between the controller and the transmitter has high electromagnetic interference resistance and no potential connection, and the slow I/O module of ABB S800 system can be added to any equipment, depending on the project in detail.

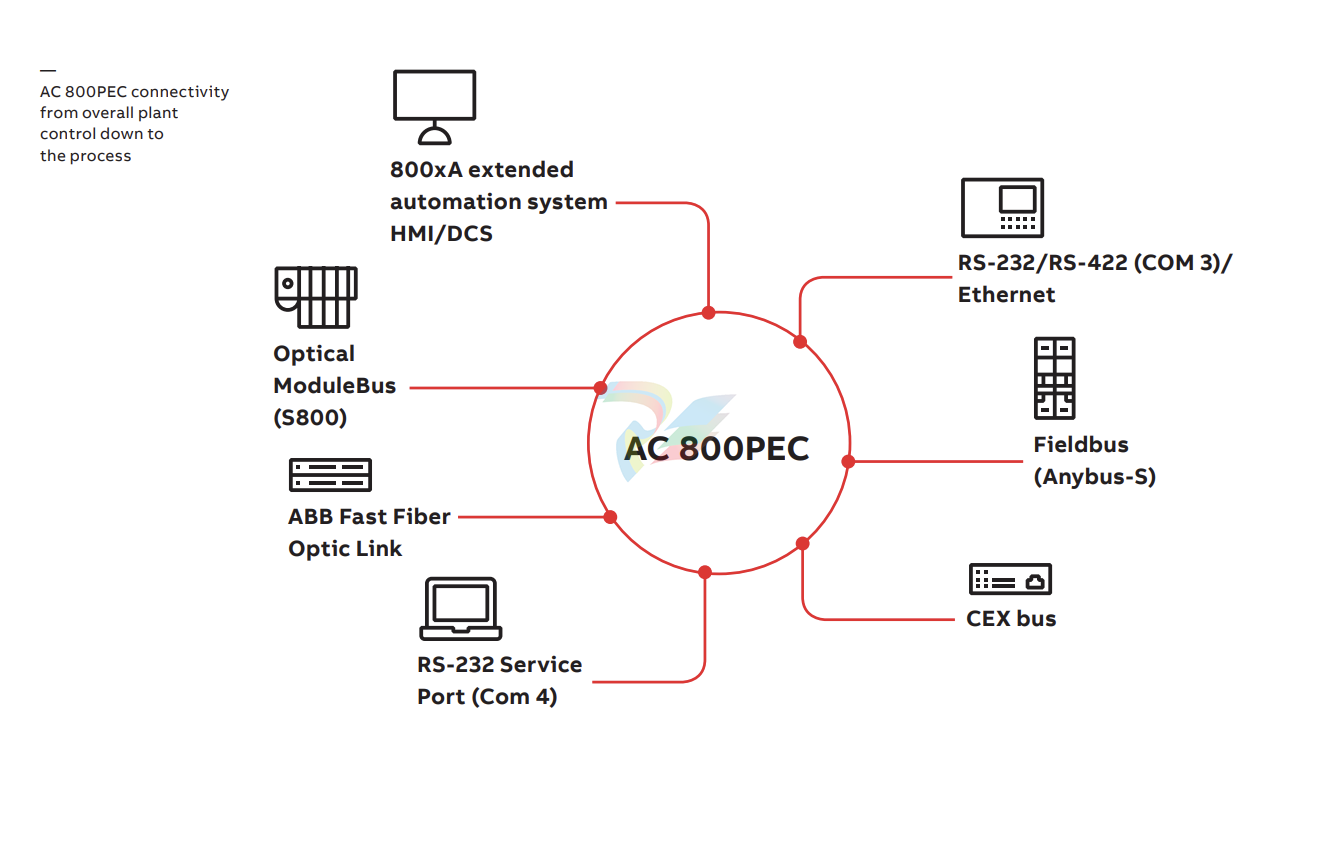

Multifunctional and reliable AC 800PEC is suitable for any application to be seamlessly integrated into factory control. In today's demanding market, it is necessary for operators to provide not only the best performance, but also transparency. In this respect, AC 800PEC offers a wide range of possibilities. Integrated communication ensures transparent factory-wide data exchange and control-from overall factory control to independent processes. ABB system 800xA and powerful AC 800PEC controllers promise the high-grade solution of unified automation and seamless integration of process control system throughout the factory. AC 800PEC supply connection, using this machine (built-in) or additional functions. This machine (depending on the equipment): MMS Modbus TCP slave IEC61850 ABB fast optical fiber link ABB Drivebus (DDCS) IbaPDA optical module bus (S800) CANopen add-on component uses ABB CEX module: ABB Drivebus (DDCS). Profibus master DPV1 Modbus RTU S100 I/O Masterbus 300 uses Anybus module CANopen to control the network DeviceNet Profibus slave profibus master DPV1 Profibus I/O Ethernet /IP.

AC 800PEC is very suitable for harsh environment-AC 800PEC has a huge installation foundation because the AC 800pec manipulator is used in different ABB solutions, which makes it possible to extract long-term life cycle experiences. Traction with particularly harsh environmental conditions is one of the most important applications of AC 800PEC. The manipulator can work in a wide temperature range (-40 to+70 C), and the oscillation conforms to the traction specification. A compact solution is an integrated unit that responds to the limited demand and promises to deal with it, and all I/O are in the same compact hardware device. Reliability is necessary-AC 800 PEC power supply is generally generated, and the excitation system used for generator control in high reliability power plants is the first requirement. Because of the short process cycle, the traditional concept of redundancy is no longer applicable. If the modular architecture of AC 800PEC is not so, it will only greatly reduce the overall complexity system, but the redundant subsystem will also provide reliability improvement. If there is a problem with a subsystem, the main controller switches to other subsystems, and these subsystems are shared so that the overall mission can still be completed. If there is something wrong with the main controller, the second controller is in a hot standby state. Accuracy of the best quality–The most demanding function of -AC 800 pec for industrial process rolling mills is thickness control. By using the powerful AC 800PEC manipulator, a new thickness control solution for cold rolling mill is based on MIMO (Multiple Input Multiple Output) control concept. The advantage for customers is that the thickness deviation is improved by up to 50%.

The AC 800PEC tool is used for all AC 800PEC.The controller handles the operation.

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

-

UniOP ECT-16-0045 High-Performance Color Touchscreen HMI

-

UniOP ERT-16 - Industrial PLC Workstation

-

UniOP ePAD04-0046 Compact Industrial Interface

-

UniOP BKDR-16 High-Reliability Monochrome Operator Interface

-

UniOP MKDR-04-004 Control Unit Panel

-

UniOP eTOP515 Series 500 HMI

-

Woodward 9907-1199 Advanced CPC-II Current-to-Pressure Converter

-

Woodward 8200-1300 High-Precision 505D Steam Turbine Controller

-

ABB PFSK130 3BSE002616R1 Core Signal Conditioning Unit

-

ABB PFSK165 3BSE027778R1 VP74201-933CW07 Signal Processing and Communication Unit

-

ABB PFSK164 3BSE021180R1 Tension sensor module and processing board

-

ABB 3BSE006505R1 PFSK142 Control board

-

ABB PFSK160A 3BSE009514R1 Regulated High-Capacity 24V DC

-

ABB PFSK162 3BSE015088R1 Signal Conditioning and Processing Board

-

ABB PFSK152 3BSE018877R1 Signal concentrator board

-

ABB PFSK151 3BSE018876R1 High-performance signal processing unit

-

ALSTOM PIB1201A 3BEC0067 Power Interface Board (PIB)

-

ALSTOM PIB310 3BHB0190 Adapter Module / Printed Circuit Board (PCB)

-

ALSTOM PIB102A 3BEB0180 Communication Card / PCB Module

-

ALSTOM BGTR8HE 24491276A1004 High-Frequency Power Controller / Rack Module

-

ALSTOM LC105A-1 Digital Discrete Output (Relay)

-

ALSTOM IR139-1 High-Efficiency Inverter / Control Board

-

ALSTOM AM164 Analog Output / Remote I/O

-

ALSTOM LE109A-1 Power System Control and Monitoring Module

-

ALSTOM UT150-1 PID temperature controller / process control board

-

ALSTOM AL132 AL132A STO0982E01 Control Motherboard / CPU Card

-

ALSTOM AS111-1 Analog Output (AO) Module

-

WATLOW AH116-2 Servo Drive / Control Module

-

WATLOW V4555724-0100 Electromechanical Contactor /Power Switch

-

Alstom KCEU142 Digital Protection Relay

-

ALSTOM MMLG01 Test block

-

WATLOW 999D,999A Digital/Analog Dual-Channel Base Unit

-

WATLOW 998D 998A Digital/Analog Dual-Channel Base Unit

-

WATLOW 999D-11FF-AARG Dual-channel digital unit with universal process outputs

-

WATLOW Wattlo 998D-22KK-ARRG is a high-performance dual-channel digital controller

-

WATLOW 996A Single-loop controller

-

WATLOW 996D-11CC-CUGR Single-loop digital controller

-

WATLOW 996D Single-Channel Digital Temperature/Process Controller

-

WATLOW 997D Digital Dual-Channel Base Unit

-

WATLOW 997A Analog Dual-Channel Variant

-

WATLOW DAC / SDAC Digital-to-Analog / Serial-to-Analog Modules

-

WATLOW MLS300-OIT Operator Interface Terminal (Keypad/Display),Discontinued

-

WATLOW CIM300 Communication Interface Module (EIA-232/485),Discontinued

-

WATLOW MLS300-CIM Control Interface Module

-

WATLOW MLS300-AIM,Analog Input Module (16-channel expansion),Discontinued

-

WATLOW MLS300-PM Processor Module (Central CPU),Discontinued

-

Watlow MLS332 32-Loop Processor Base Unit,Discontinued

-

Watlow MLS316 Multi-loop thermal controller

-

Watlow CLS208 C10000CP high-performance, 8-loop PID temperature controller

-

Watlow CAS 16CLS/CAS Multi-loop temperature controller

-

ABB CP555 1SBP260179R1001 Product Overview

-

Watlow MLS300 Multi-Loop Control System

-

Watlow 997D-11CC-JURG SERIES 997 Vertical Limit Control

-

Watlow CLS216 Multi-Loop PID Temperature Controller

-

Watlow NLS300-CIM316 Multi-Loop Control Interface Module

-

Watlow PPC-TB50 (30280-00) Precision Power Controller

-

ABB 3BSE014227R1 RF533 Central Unit

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)