- LAND

- Pacific Scientific

- Kongsberg

- Abaco

- EMERSON

- NI

- LAMBDA

- Stucke Elektronik

- LEYBELOD

- AMAT

- ICS Triplex

- Lam Research

- KUKA

- Hirschmann

- ELAU

- EATON

- Applicom

- Watlow Anafaze

- Meggitt Vibro-meter

- Carrier

- Other

- ROCKWELL

- Rolls-Royce

- SAACKE

- Yokogawa

- B&R

- Reliance Electric

- Seifert

- A-B

- Weimeide Metso

- KEBA

- HIMatrix

- Valmet

- Schneider

- Prosoft

- PEPPERL+FUCHS

- Honeywell

- Woodward

- GE

- GEA Westfalia Separator

- Bently Nevada

- ALSTOM

- Foxboro

- MOTOROLA

- Fanuc

- VMIC

- KOLLMORGEN

- SEW

- Rexroth

- AEROTECH

- TOSHIBA

- TmeIC

- Sumitomo

- SOCAPEL SOCASIN

- SMC

- Stromag

- SIEMENS

- SCHUMACHER

- ABB

- MOOG

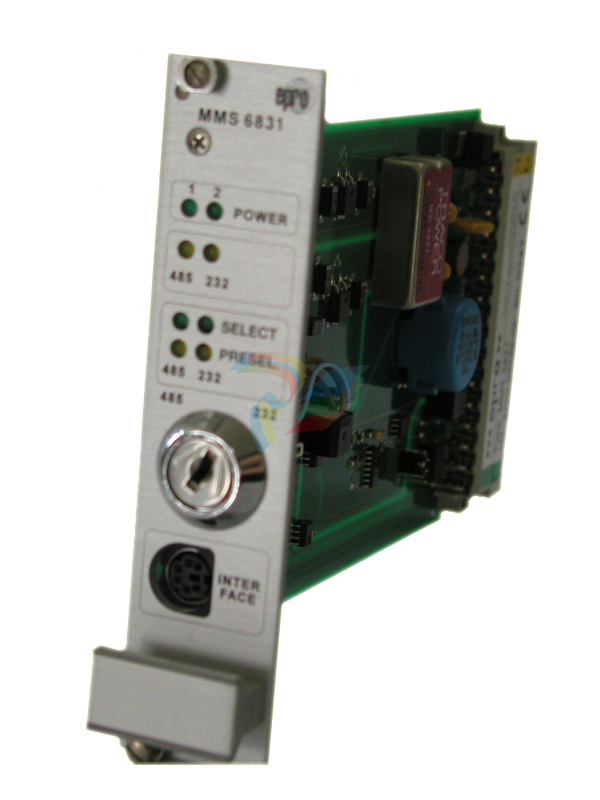

- EPRO

- EMERSON

- Triconex

EPRO MMS6210 Dual-channel axial displacement measurement module

MMS6210 Dual-channel axial displacement measurement module MMS6210

Features

Dual-channel axial displacement measurement module, monitoring axial displacement and expansion difference.

It can be replaced during operation, used independently, and has redundant power input.

Extended self-checking function, built-in sensor self-checking function, password protection operation level.

Applicable eddy current sensor PR642. Series plus preamplifier CON0X1

The RS232/485 ports are used for on-site configuration and communication, and measurement values can be read out.

Built-in linearization processor.

Record and store the measurement data of the most recent start/stop.

Application

The dual-channel axial displacement measurement module MMS6210 measures the movement of shafts, such as: axial displacement, expansion difference,

thermal expansion, and radial shaft position. The signal is taken from the eddy current displacement sensor.

The measurement of this module can be combined with that of other modules to form a turbomachinometer protection system,

or be provided as input to the analysis and diagnosis system, fieldbus system, distributed control system, power plant/main computer, network such as WAN/LAN network, Ethernet.

For steam engines, gas engines, water turbines, compressors, fans, centrifuges and other turbomachinery. The use of this system can enhance the efficiency of operation, the safety of operation and extend the service life of machinery.

The MMS6210 is a dual-channel axial displacement measurement module that can use eddy current displacement sensors to measure axial movement to monitor and protect various types of turbine machinery, such as steam turbines, gas turbines, compressors, fans, gearboxes, blowers, centrifuges, etc.

The output of the sensor, that is, the input of the module, represents the gap from the front end of the sensor to the surface of the object being measured. The signal is processed by the MMS6210 module and converted into a standard signal output in proportion to the set working mode. The other parts of the module provide functions such as alarm, sensor power supply, module power supply, detection of channels and sensors, and signal filtering.

It is equipped with a built-in microprocessor, allowing the working mode and parameters to be set and all measurement values to be read via on-site portable devices or remote communication buses.

The last start/stop process is stored in the module and can be displayed on the computer.

Signal input

a." The MMS6210 has two independent eddy current sensor signal inputs:

SENS 1H (z8) /SENS 1L (z10) and SENS 2H (d8) /SENS 2L (d10).

The matching eddy current sensor is the PR642X series eddy current sensor and the corresponding preamplifier produced by the German company epro. Sensors of the same type produced by other manufacturers can also be used. The input voltage range is -1... -22 V dc.

The module provides two -26.75V DC power supplies for the sensor:

SENS 1+ (z6) /SENS 1- (b6) and SENS 2+ (d6) /SENS 2- (b8).

The sensor signal can be detected at the SMB interface on the front panel of the module.

b." The module has two voltage inputs, EI1 (b14)/EI2 (b16), and their functions will be introduced in the next chapter.

c. The module is also equipped with a key signal input (must be greater than 13V), which is necessary for the speed control mode.

2. Signal output

a." Output of characteristic values

The module has two current outputs representing characteristic values: I1+ (z18)/I1- (b18) and I2+ (z20)/I2- (b20), which can be set to 0... 20mA or 4... 20mA.

The module has two zeros representing the eigenvalues... 10V voltage output: EO 1 (d14)/EO 2 (d16).

b." The module provides two paths of 0... 10 V dc voltage output: NGL1 (z12)/NGL2 (d12).

This output is proportional to the distance between the sensor and the measured surface.

3. Limit monitoring

a." Alarm value

In the dual-channel independent measurement mode, each channel can be separately set with two sets of alarm values and danger values.

The specific description of the dual-channel combined use mode is provided later. To prevent repeated alarms triggered by changes in the measured value near the limit value, an alarm lag value can be set at 1... of the full scale. Choose between 20%.

b." Limit multiplier and multiplier coefficient X

In special circumstances, such as when the critical speed is exceeded, to avoid unnecessary alarms or trips, the limit multiplier function can be activated in the software and the multiplier coefficient X (1.00 to 5.00) can be set. When using this function, d18 should be at a low level. The multiplication coefficient X simultaneously affects both the alarm value and the danger value.

c. Alarm output

The module provides four alarm outputs:

Channel 1: Danger D1-C, D1-E (d26. d28), Alarm A1-C, A1-E (b26. b28)

Channel 2: Danger D2-C, D2-E (d30. d32), Alarm A2-C, A2-E (b30. b32)

Whether the alarm is triggered upwards or downwards, an alarm output will be given.

"d. Alarm hold function

By using this function, the alarm status will be maintained. Only through the Reset latch channel 1/2 command in the software can the alarm be cancelled after the alarm condition disappears.

e." Alarm output mode

When using SC-A (Alarm d24) and SC-D (Danger z24), the alarm output mode can be selected:

When SC- is an open circuit or a high potential (+ 24V), the alarm output is normally open.

When SC- is at a low potential (0 V), the alarm relay is normally closed.

To avoid power failure causing an alarm and facilitate plugging and unplugging while powered on, it is recommended to choose an alarm output that is always on.

f." No alarm allowed

The alarm output will be disabled in the following circumstances:

- Module failure (power supply or software failure).

The delay period after power-on and the 78-second delay period after power-off and setting.

The module temperature exceeds the dangerous value.

- Disable the external alarm and set ES (z22) to 0V.

When the limit suppression function is activated, the input level is 0.5V lower than the lower limit of the range or 0.5V higher than the upper limit of the range.

4. Status monitoring

The module continuously checks the measurement circuit, provides indications when faults are detected, and locks the alarm output when necessary.

There are three ways for status indication:

- Through the "Channel Normal" indicator light on the front panel;

- Output 1/2 through "Channel Normal";

- Displayed on Device status via computer and configuration software.

a." Channel monitoring

The module checks the DC voltage value of the input signal. When the input signal exceeds the set upper limit of 0.5V or falls below the set lower limit of 0.5V,

a channel error indication (sensor short circuit or open circuit) is given.

b." Normal channel indication

When the channel is normal, the indicator light is green.

The changes of the indicator light are as follows:

- The indicator light is off... "Fault

-Slow flicker (FS) 0.8Hz... Channel status

- Fast Flash (FQ) 1.6Hz... Module status

After being powered on

- Normal startup period... The two indicator lights flash synchronously for 15 seconds.

- The module is not configured... The two indicator lights flash alternately.

- Module not calibrated *... All the indicator lights flash alternately. When this phenomenon occurs, it should be sent to the factory for handling.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

-

Woodward ESDR 4 Current Differential Protection Relay

-

Woodward easYgen-3000 Genset Control for

-

Woodward CPC-II Current-to-Pressure Converter

-

Woodward 8290-189-EPG-installation-manual 8290-044

-

Woodward Product Change Notification 06946A

-

Woodward Product Change Notification 06912

-

Fisher™ 4660 High-Low Pressure Pilot

-

Flexible digital protection and control equipment SYMAP®

-

Woodward 723PLUS Digital Control

-

Woodward 505 Digital Controller For steam turbineses

-

Woodward 85018V2 505E Digital Governor for Extraction Steam Turbines

-

Woodward 85018V1 Turbine Control Parameters

-

Woodward 26871 505 Enhanced Digital Control for Steam Turbines

-

Woodward 03365 505E (Extraction / Admission)

-

KONGSBERG RMP420-Remote Multipurpose Input/Output

-

KONGSBERG RCU501 Remote Controller Unit

-

KONGSBERG RCU500 Remote Controller Unit

-

K-Gauge TOP KONGSBERG Tank Overfill Protection SystemFeatures

-

Kongsberg DPS112 DGNSS (DGPS/DGLONASS) sensor

-

Kongsberg d0000930 presafe-atex-report signed

-

HIMax TECHNICAL FACTS X Series

-

GE Multilin F650

-

GE MIF II - Legacy

-

GE PQM II Power QualIty Meter

-

Hydran 201Ti Mark IV Essential DGA monitoring for transformers

-

alstom AMS42/84 5B Amplifier SystemAmplifier Technology at its Best.

-

GE VMIVME-5576 Fiber-Optic Reflective Memory with Interrupts

-

GE Multilin 750/760 - Legacy Feeder Protection System

-

GE Fanuc Automation VMICPCI-7806 Specifications

-

GE VMIVME-7807 VME-7807RC* Intel® Pentium® M-Based VME SBC

-

GE Fanuc Automation VMIVME-7750 Specifications

-

FOXBORO Compact FBM240. Redundant with Readback, Discrete

-

FOXBORO FBM208/b, Redundant with Readback, 0 to 20 mA I/O Module

-

FOXBORO FBM201e Analog Input (0 to 20 mA) Interface Modules

-

Foxboro DCS FBM206 Pulse Input Module

-

FOXBORO FBM216 HART® Communication Redundant Input Interface Module

-

FOXBORO Z-Module Control Processor 270 (ZCP270)

-

Foxboro DCS Compact FBM241/c/d, Redundant, Discrete I/O Modules

-

Foxboro FBM223 PROFIBUS-DP™ Communication Interface Module

-

Foxboro DCS FBM204. 0 to 20 mAI/OModule

-

Foxboro FBM239, Discrete 16DI/16DO Module

-

Foxboro FBM202 Thermocouple/mV Input Module

-

Foxboro E69F Current-to-Pneumatic Signal Converter

-

EMERSON M-series Intrinsically Safe I/O

-

Configuration for AMS 6500 Protection Monitors

-

EMERSON DeltaV™ M-series Traditional I/O

-

EMERSON DeltaV™ SQ Controller

-

AEROTECH Ndrive MP Hardware Manual

-

AEROTECH Ndrive HPe 10/20/30

-

AEROTECH Ndrive CP Hardware Manual

-

AEROTECH Ndrive Linear Series Digital Servo Amplifiers – Linear

-

AEROTECH Ndrive HP 10/20/30 P/N: EDU170

-

AEROTECH EDU176_Ndrive_HL

-

ADVANCEDMOTION CONTROLS Analog Servo Drive 120A10

-

GE JPAX-H

-

GE JPAX family

-

GE Industry Leading Experience

-

GE Ether-1000 Unit

-

GE Cyber Secured Service Unit

-

GE Lentronics E1MXe Multiplexer

-

GE TTMX Teleprotection Terminal

-

GE Lentronics T1 Multiplexer

-

GE Lentronics JungleMUX SONET Multiplexer

-

GE Lentronics E1MX Multiplexer

-

GE Lentronics TN1Ue SDH Multiplexer

-

GE Lentronics TN1U SDH Multiplexer

-

GE Gridcom DXC Family Access and Transmission Multiplexer

-

GE Advanced Network Management

-

GE Lentronics VistaNET Network Management System (NMS)

-

ABB System Controller Connect

-

Ethernet Module EI 803F ABB

-

ABB Ethernet Modules EI 802F

-

ABB Ethernet Modules EI 801F

-

ABB Power Supply SD 802F / SD 812F

-

ABB Power Supply SA 801F / SA 811F

-

ABB Basic Unit PM 802F /PM 803F

-

Control product - Soft starter PST/PSTB (Intelligent Type) ABB

-

ABB CP450 Installation and Operation Manual

-

ABB ompact 800 5.1 Product Catalog

-

ABB Panel 800 version 6

-

ABB Panel 800 Version 6- Panel Builder Version 6.0-1

-

ABB Control Panels CP405 Control Panels CP408

-

ABB PowerUP for medium voltage drives

-

GE MiCOM P40U Connect MiCOM P40 IEDs to PCs with USB ports

-

Reason RT431 GPS Precision-Time Clock GE

-

GE Reason RT430 GNSS Precision-Time Clocks

-

GE Reason H49 PRP/HSR Redbox Switch

-

GE Reason S20 Managed Ethernet Switches

-

GE Gridcom DIP.net

-

Central Control Station at Jaenschwalde mineLausitzer Braunkohle AG, Germany 2000

-

ABB Ability™ System 800xA Advant® Master S400 I/O to S800 I/O Evolution

-

ABB with Advant Controller 400 series

-

Advant™Automation with MOD 300™ Software

-

Bently 2300/20 and 2300/25 2300 Vibration Monitors

-

ABB NGC8206 Natural Gas Chromatograph Dual Unit

-

MOTOROLA MVME2400 TM VME Processor Modules

-

5320 Series Foxboro DCS Control Network Ethernet Equipment

-

ExtremeSwitching™ 5420 Series

-

WOODWARD EGCP-3 Engine Generator Control Package LS (Load Sharing)

-

5520 Series Universal Edge/Aggregation-Switch Platform

-

X440-G2 Series

-

EMERSON FloBoss™ S600 Flow Manager Specification Sheet

-

KONGSBERG RAIV400 Remote Analogue Input, Voltage

-

RMP420-Remote Multipurpose Input/Output Kongsberg

-

610 serie ABB Feeder Protection REF610 Product Guide

-

Triconex 3351S2 Controller Features

-

HBRF Megamax – Emax2 Air Circuit Breaker ABB

-

ABB MEASUREMENT & ANALYTICS | DATA SHEET LS4000 Diode laser analyzer

-

Pressductor Pillowblock Load Cells Vertical Measuring PFCL 201 User manual

-

PARKER BFR5K Series

-

AC 900F controller ABB

-

Uniop ePAD05 and ePAD06 Technical description

-

Hitachi ABB Communication Unit 560CMR02

-

MOTOROLA MVME5500 Series VME Single-Board Computer

-

ABB Symphony Plus SD Series HPC800 controller

-

ABB AC800M Controller Hardware System

-

ABB AC800M PROFIBUS DP Installation System

-

ABB Freelance 800F AC800F Control systems

-

ABB Compact control system replaces PLC AC700F

-

abb Triguard SC300E 3BNP004720R101 TMR Safety Products

-

ABB Distributed busbar protection REB500

-

ABB Advant Controller 400 series

-

ABB MEASUREMENT & ANALYTICS | PRODUCT GUIDE

-

PACIFIC SCIENTIFIC PC800 PC832 PC830 Series Digital Brushless Servo Drive

-

PSS41S-3FDCTSAA Triconex DCS System Access Application Driver for Field Device Controller 280

-

Alstom controller of ICP232 029.359325

-

DEIF DU-2/MKIII Paralleling And Protection Unit General information

-

ABB 3ADT220134R0001 SDCS-COM-81 board 10MBd

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)