FOXBORO Compact FBM240. Redundant with Readback, Discrete

Compact FBM240. Redundant with Readback, Discrete

Output and Discrete Input Module

Overview

The Compact FBM240is an 8 channel input and 8 channel output Foxboro™ DCS

Fieldbus Module (FBM) available as a single or redundant module. A redundant pair

of the modules combine to provide redundancy at the FBM level, with field I/O wired to

one commontermination assembly (see Figure 1). Each module independently holds

the output(s) at its specified output value(s), and each independently reads back its

observed value of the output.

This module is part of the Compact 200 Series I/O subsystem described in Compact

200 Series I/O Subsystem Overview (PSS 41H-2COV).

Aredundant contact output block in the control software validates each output in

conjunction with information to/from the module.

Features

• Eight discrete outputs/Eight discrete voltage monitor inputs

• Eight discrete inputs read back the voltage across the relay contacts. Sets the

channel BAD if the state of the contact disagrees with the state of the

corresponding output channel

• Monitors each FBMoutput and sets the output channel BAD if the output is in the

wrong state

• Single or redundant module

• Termination Assemblies (TAs) for locally or remotely connecting field wiring to the

Compact FBM240

• Supports discrete relay outputs capable of switching:

◦ 10Aat80to120VAC,or

◦ 5Aat80to125VDC,or

◦ 5Aat15to30VDC,or

◦ 5Aat80to120VAC

• Supports channel-isolated discrete I/O:

◦ 15-60VDC@2A,fusedoutputs

◦ 15-60VDCinputs

NOTE: Support for this termination assembly and the new Fail-Safe

configuration options described in Fail-Safe, page 6 require version 1.40N or

later firmware.

• Redundantoperation failure detection

◦ Outputcontact monitor readback and high coverage of internal FBM detected

failures allows redundant partner to automatically continue to drive discrete

outputs and to monitor inputs

• Internal per channel output demand state failure detection

◦ OutputChannel is marked BAD in both Single and Redundant Operation if the

demand state read-back indicates a state of miss-compare

Internal Readback of Output

The Compact FBM240has8internal readback channels, one per each output

channel, used to verify that the output has changed to the requested state. These

channels read the voltage across the relay contacts on the relay termination

assemblies. The states of these channels are displayed on LEDs on the front panel of

the Compact FBM240. When external power is applied to the relay contact of each

channel, the LED for that channel is ON when the relay contact is CLOSED, and OFF

when the relay contact is OPEN. If the state of the contact disagrees with the state of

the corresponding output channel, the channel is marked BAD.

The FBMalso monitors each of its eight outputs and sets the corresponding output

channel BAD if the output is in the wrong state.

If the channel or input power is marked BAD, the CP presents that information to the

Foxboro DCS for display as a System Management alarm and as a control block

alarm

Redundant Outputs

Aredundant contact output function block, COUTR, is used for each redundant pair of

outputs. The COUTR block handles output writes and initialization logic for the

redundant channels. On each write of the COUTR block, identical output writes are

sent to both modules, fully exercising the Fieldbus and the logic circuitry of each

module. You can select a sustained output that follows the block input or a pulsed

output with a selectable pulse width.

Whenafailure is detected in one of the modules, its output is marked BAD and the

corresponding channel in the good module automatically continues to drive the

discrete outputs.

Each output channel drives an externally powered load. Power for each Compact

FBM240module is diode OR’d together in the redundant adapter to help assure

redundant power. The microprocessor of each module executes the digital output

application program, plus diagnostic routines that validate the health of the FBM.

Fail-Safe

Configurable options for output safety include:

• Digital Output Fail-Safe Fallback Data- specifies the channel fallback value (0 or

1) for each of the eight digital outputs

• Maskoption- determines which of the eight digital outputs hold its current value

and which outputs assume the fallback values

• Fieldbus Fail-Safe Delay Time- length of time the FBM waits for a communication

from the CP before entering a communications fail

Redundant Modules

For redundant modules, the Fail-Safe Fallback Data and mask options are

configurable. An additional option is provided so that the module data will fall back to

zero (0) when the module is put off-line for maintenance functions so that it will not

interfere with the remaining module which is still on-line.

The Compact FBM240requires version 1.40N or later firmware to support this feature.

Single Modules

For single modules, the Fail-Safe Fallback Data and Mask options are configurable.

Compact Design

The Compact FBM240’s design is narrower than the standard 200 Series FBMs. It

has a rugged Acrylonitrile Butadiene Styrene (ABS) exterior for physical protection of

the circuits. Enclosures specially designed for mounting the FBMs provide various

levels of environmental protection, up to G3 harsh environments, per ISA Standard

S71.04.

High Reliability

The redundancy of the module pair, coupled with the high coverage of detected faults,

provides a very high subsystem availability time.

The module performs signal conversion required to interface electrical input signals

from field sensors to the optionally redundant Fieldbus. It executes the Discrete I/O

program with the following configurable options: Input Filter Time, Fail-Safe

Configuration, and Sustained or Momentary Outputs. If the Momentary Output

configuration is selected, then Pulse Output Interval is also configurable.

Whenredundant, either module may be replaced without upsetting field input or

output signals to the good module. The module can be removed/replaced without

removing field device termination cabling, power, or communications cabling

Easy Removal/Replacement

The module mounts on a Compact 200 Series baseplate. Two screws on the FBM

help secure the module to the baseplate.

Redundant modules must be located in adjacent positions on the baseplate, with the

first module located in an odd-numbered position (for example, the positions labelled

“3” and “4”). To achieve redundancy, a redundant adapter module is placed on the two

adjacent baseplate termination cable connectors to provide termination for a single

cable (see Figure 1). A single termination cable connects from the redundant adapter

to the associated termination assembly (TA).

Whenredundant, either module may be replaced without upsetting field input signals

to the good module. Each module can be removed/replaced without removing field

termination cabling, power, or communications cabling.

Modular Baseplate Mounting

The Compact FBM240module mounts on a DINrail mounted Modular Baseplate,

which accommodates up to four or eight FBMs. The Modular Baseplate is either DIN

rail mounted or rack mounted, and includes signal connectors for the redundant

Module Fieldbus, redundant independent DC power, and termination cables.

Redundant modules must be located in odd and even adjacent positions on the

baseplate (positions 1 and 2. 3 and 4. 5 and 6. or 7 and 8). To achieve the

redundancy, a redundant adapter module is placed on the two adjacent baseplate

termination cable connectors to provide a single termination cable connection (See

Figure 1. page 3).

To system configurator applications and to other systems monitoring through SMON,

Foxboro DCS System Manager, and SMDH, redundant FBM240s appear to be

separate, nonredundant modules. The functional redundancy for these modules is

provided by their associated control blocks.

Redundant Modules in Foxboro DCS HMI

The redundant pair of modules appear as two independent modules to system

management software applications (such as Foxboro DCS System Manager and

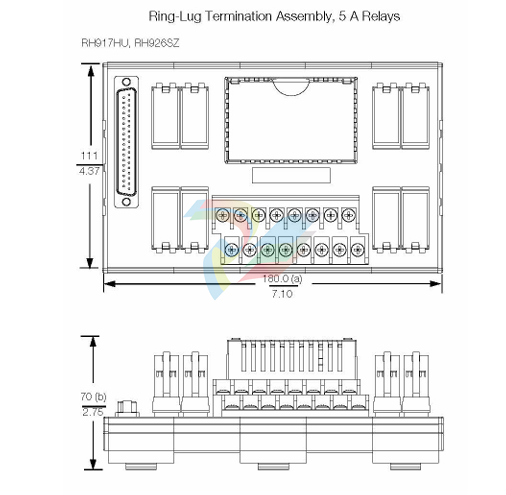

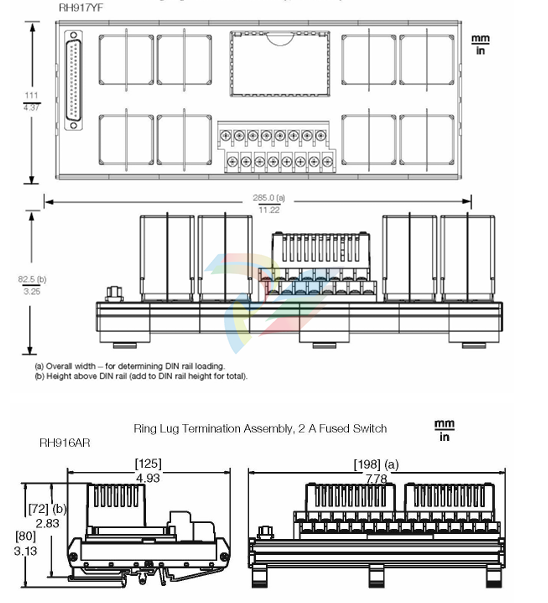

Termination Assemblies

Field I/O signals connect to the FBM subsystem via DIN rail mounted termination

assemblies (TAs). The TAs used with the Compact FBM240 provide:

• Outputsignal connection points

• External power connection point

• 5Aunsealedrelay or a 10 Aunsealed relay for each output

• 15-60VDCswitch andvoltage monitor inputs

The relay TAs have a high voltage input circuit that monitors the voltage across the

contacts of each output relay. Monitor circuits are located on daughter card

assemblies mounted on the TAs. There are two daughter cards per TA, each with four

monitor circuits. The TAs are:

• RH917YF-80to125VDCat5Aor80to120VACat10A

• RH917HU-80to120VACat5A

• RH926SZ-15to30VDCat5A

• RH916AQ/RH916AR-15to60VDCvoltagemonitor and 2 Aswitch

NOTE: WhentheCompact FBM240output opens, the TA contacts still apply

current to the circuit due to the TA’s readback circuitry, as described in Table 2 and

Table 3.

The RH916AQ/ARpassive TA provides fused 2 A outputs and independent inputs for

use with 15-60 VDC.

The redundant adapter connects the redundant FBM’s baseplate connectors together.

The redundant adapter provides a single termination connection to a single TA.

The DIN rail mounted termination assemblies connect to the redundant adapter by

means of a removable termination cable. The cable is available in a variety of lengths,

up to 30 meters (98 feet), allowing the termination assemblies to be mounted as

needed by plant design.

Visual Indicators

Red andgreen light-emitting diodes (LEDs) incorporated into the front of the modules

provide visual status indications of FBM functions, as well as the discrete states of the

individual output points.

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

-

UniOP ECT-16-0045 High-Performance Color Touchscreen HMI

-

UniOP ERT-16 - Industrial PLC Workstation

-

UniOP ePAD04-0046 Compact Industrial Interface

-

UniOP BKDR-16 High-Reliability Monochrome Operator Interface

-

UniOP MKDR-04-004 Control Unit Panel

-

UniOP eTOP515 Series 500 HMI

-

Woodward 9907-1199 Advanced CPC-II Current-to-Pressure Converter

-

Woodward 8200-1300 High-Precision 505D Steam Turbine Controller

-

ABB PFSK130 3BSE002616R1 Core Signal Conditioning Unit

-

ABB PFSK165 3BSE027778R1 VP74201-933CW07 Signal Processing and Communication Unit

-

ABB PFSK164 3BSE021180R1 Tension sensor module and processing board

-

ABB 3BSE006505R1 PFSK142 Control board

-

ABB PFSK160A 3BSE009514R1 Regulated High-Capacity 24V DC

-

ABB PFSK162 3BSE015088R1 Signal Conditioning and Processing Board

-

ABB PFSK152 3BSE018877R1 Signal concentrator board

-

ABB PFSK151 3BSE018876R1 High-performance signal processing unit

-

ALSTOM PIB1201A 3BEC0067 Power Interface Board (PIB)

-

ALSTOM PIB310 3BHB0190 Adapter Module / Printed Circuit Board (PCB)

-

ALSTOM PIB102A 3BEB0180 Communication Card / PCB Module

-

ALSTOM BGTR8HE 24491276A1004 High-Frequency Power Controller / Rack Module

-

ALSTOM LC105A-1 Digital Discrete Output (Relay)

-

ALSTOM IR139-1 High-Efficiency Inverter / Control Board

-

ALSTOM AM164 Analog Output / Remote I/O

-

ALSTOM LE109A-1 Power System Control and Monitoring Module

-

ALSTOM UT150-1 PID temperature controller / process control board

-

ALSTOM AL132 AL132A STO0982E01 Control Motherboard / CPU Card

-

ALSTOM AS111-1 Analog Output (AO) Module

-

WATLOW AH116-2 Servo Drive / Control Module

-

WATLOW V4555724-0100 Electromechanical Contactor /Power Switch

-

Alstom KCEU142 Digital Protection Relay

-

ALSTOM MMLG01 Test block

-

WATLOW 999D,999A Digital/Analog Dual-Channel Base Unit

-

WATLOW 998D 998A Digital/Analog Dual-Channel Base Unit

-

WATLOW 999D-11FF-AARG Dual-channel digital unit with universal process outputs

-

WATLOW Wattlo 998D-22KK-ARRG is a high-performance dual-channel digital controller

-

WATLOW 996A Single-loop controller

-

WATLOW 996D-11CC-CUGR Single-loop digital controller

-

WATLOW 996D Single-Channel Digital Temperature/Process Controller

-

WATLOW 997D Digital Dual-Channel Base Unit

-

WATLOW 997A Analog Dual-Channel Variant

-

WATLOW DAC / SDAC Digital-to-Analog / Serial-to-Analog Modules

-

WATLOW MLS300-OIT Operator Interface Terminal (Keypad/Display),Discontinued

-

WATLOW CIM300 Communication Interface Module (EIA-232/485),Discontinued

-

WATLOW MLS300-CIM Control Interface Module

-

WATLOW MLS300-AIM,Analog Input Module (16-channel expansion),Discontinued

-

WATLOW MLS300-PM Processor Module (Central CPU),Discontinued

-

Watlow MLS332 32-Loop Processor Base Unit,Discontinued

-

Watlow MLS316 Multi-loop thermal controller

-

Watlow CLS208 C10000CP high-performance, 8-loop PID temperature controller

-

Watlow CAS 16CLS/CAS Multi-loop temperature controller

-

ABB CP555 1SBP260179R1001 Product Overview

-

Watlow MLS300 Multi-Loop Control System

-

Watlow 997D-11CC-JURG SERIES 997 Vertical Limit Control

-

Watlow CLS216 Multi-Loop PID Temperature Controller

-

Watlow NLS300-CIM316 Multi-Loop Control Interface Module

-

Watlow PPC-TB50 (30280-00) Precision Power Controller

-

ABB 3BSE014227R1 RF533 Central Unit

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

UniOP eTOP308 ETOP308U301 HMI Panel

-

UniOP ePALM10-0061 Handheld Robot Trainer

-

UniOP CP01R-04 CP05R-04 and CP01F-02

-

Uniop MD02R-04 - MD02R-04-0045 Industrial PLC Workstation

-

Uniop Cp02r-04-0021 Operating Interface

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)