Pressductor Pillowblock Load Cells Vertical Measuring PFCL 201 User manual

USE OF SYMBOLS

This publication includes the following symbols with information regarding safety or other important information:

CAUTION Caution icon indicates important information. Risk of damage to equipment, property or software.

DANGER Danger icon indicates a hazard which could result in personal injury or even death.

ELECTRICAL Electrical warning icon indicates the presence of a hazard which could result in electrical shock.

ESD ESD icon indicates that electrostatic discharge precautions are needed.

Information Information icon alerts the reader to relevant facts and conditions.

Tip Tip icon advise how to design your product or how to use a certain function.

NOTICE

The information in this document is subject to change without notice and should not be construed as a commitment by ABB AB. ABB AB assumes no responsibility for any errors that may appear in this document.

In no event shall ABB AB be liable for direct, indirect, special, incidental or consequential damages of any nature or kind arising from the use of this document, nor shall ABB AB be liable for incidental or consequential damages arising from use of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without ABB AB’s written permission, and the contents thereof must not be imparted to a third party nor be used for any unauthorized purpose. The software described in this document is furnished under a license and may be used, copied, or disclosed only in accord ance with the terms of such license.

Description

General

The load cell is machined from a single piece of stainless steel. The sensors are machined directly in the piece of steel and are positioned so that they are sensitive to force in the direction of meas urement and insensitive in other directions.

The load cell is mounted on a base with four screws, and the bearing housing is mounted on top of the load cell with four screws.

Every load cell comes calibrated and temperature compensated.

The load cells PFCL 201C/201CE/201CD are available in four measurement ranges, all variants have the same external dimensions.

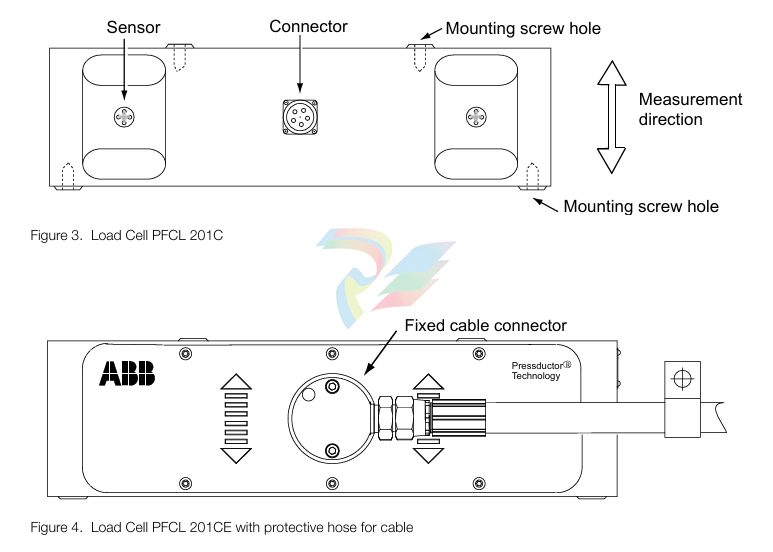

The load cell PFCL 201C is equipped with a connector for the pluggable connection cable. The load cell PFCL 201CE has a fixed connection cable with protective hose. The load cell PFCL 201CD is provided with an acid-proof cable gland with a fixed PTFE- insulated connection cable.

Definitions

Nominal load

Nominal load, Fnom, is the maximum load in the measurement direction for which the load cell is dimensioned to measure within the specified accuracy class. The load cell is calibrated up to Fnom.

Sensitivity

Sensitivity is defined as the difference in output values between nominal load and zero load.

Accuracy and Accuracy Class

Accuracy class is defined as the maximum deviation, and is expressed as a percentage of the sen sitivity at nominal load. This includes linearity deviation, hysteresis and repeatability error.

Linearity Deviation

Linearity deviation is the maximum deviation from a straight line drawn between the output values at zero load and nominal load. Linearity deviation is related to the sensitivity.

Hysteresis

Hysteresis is the maximum difference in the output signal at the same load during a cycle from zero load to nominal load and back to zero load, related to the sensitivity at nominal load. The hysteresis of a Pressductor transducer is proportional to the load cycle.

Repeatability error

Repeatability error is defined as the maximum deviation between repeated readings under identical conditions. It is expressed as a percentage of the sensitivity at nominal load.

Compensated temperature range

The temperature drifts of the load cell have been compensated for in certain temperature ranges. That is the temperature range within which the specified permitted temperature drifts (i.e. zero point and sensitivity drifts) of the load cell are maintained.

Working temperature range

Working temperature range is the temperature range within which the load cell can operate within a specified accuracy. The maximum permitted temperature drifts (i.e. zero point and sensitivity drifts) of the load cell are not necessarily maintained in the whole working temperature range.

Storage temperature range

Storage temperature range is the temperature range within which the load cell can be stored.

Zero point drift with temperature

Zero point drift is defined as the signal change with temperature, related to the sensitivity, when there is zero load on the load cell.

Sensitivity drift with temperature

Sensitivity drift is defined as the signal change with temperature at nominal load, related to the sen sitivity, excluding the zero point drift.

Compression

Compression is the total reduction in the height of the load cell when the load is increased from zero to the nominal value.

Measuring principle of the sensor

The measuring principle of the sensor is based on the Pressductor® technology and the fact that the permeability of a magnetic material changes under mechanical stress.

The sensor is a membrane machined in the load cell. Primary and secondary windings are wound through four holes in the load cell so that they cross at right angles.

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

-

Stucke Elektronik SYMAP®EC Engine Control

-

Stucke Elektronik SYMAP®ARC Arc protection system

-

Stucke Elektronik SYMAP®R Digital protection system

-

Stucke Elektronik SYMAP® Compact Digital protection and control equipment

-

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

-

LEYBELOD TURBOVAC 361 (C) Suspension turbomolecular pump

-

LAND M2300/1100C-V Industrial Control Module

-

LAMBDA LZS-1500-3 Single Output Industrial Power Supplies

-

LAMBDA LZS-A1500-3-001 POWER SUPPLY

-

LAMBDA HWS1500-24 Power supply

-

Kongsberg K-Chief Control Room Panel (CRP) 603525

-

Kongsberg MSI-12 Input/Output Module 339368

-

Kongsberg dPSC Dual Process Segment Controller Module 8100183

-

HHirschmann Modular OpenRail Fast Ethernet switch 8-24 ports MS20-1600SAAEHH08.0

-

Hirschmann MM20-Z6Z6Z6Z6SAHH ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann MM2-2FXM3/2TX1 ETHERNET / Fast-ETHERNET Media Modules

-

Hirschmann Industrial ETHERNET Switch MICE MS20/MS30

-

Hirschmann MACH102-24TP-FR Gigabit Ethernet industrial workgroup switch

-

Hirschmann MM2-4TX1 MICE switch medium module

-

Hirschmann MICE switch medium module MM2-2FXS2

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

NI Controller for VXI VXIPC-871B

-

GE VMIVME-1150 Serial Communications Controller

-

GE Hydran M2-X Enhanced Monitoring with Extended Sensor Life

-

GE IC660BBD022 I/O module

-

GE Digital Energy D20 Analog Input Module

-

Foxboro FBM I/O cards PBCO-D8-009

-

GE SR750-P5-G5-S5-HI-A20-R-E Multilin Relay

-

ABB 3BSE019050R1000 PFTL 301E 1,0kN, Load cell

-

Foxboro DNBT P0971WV Dual-node bus module of I/A series

-

EPRO MMS6210 Dual-channel axial displacement measurement module

-

EMERSON PMCspan PMC Expansion Mezzanine

-

EMERSON KJ3242X1-BK1 12P4711X042 S-Series H1 Card

-

EMERSON KJ4006X1-BD1 Interface Terminal Block

-

EMERSON KJ4001X1-CK1 40-Pin Mass Termination Block

-

ABB UCD224A103 Industrial controller module

-

ABB ARCOL 0339 Solid-state motor controller

-

ABB UFC718AE01 HIEE300936R0101 Main Circuit Interface Board

-

Abaco VME-REPEATL-485 VMEBus Repeaters

-

Abaco VME-4900 Digital-to Synchro/Resolver Board

-

Abaco VME-4911 digital converter board

-

Abaco XM-664-80 Transition module with rear I/O access to VIPC664

-

Abaco TPMCC 6U VME triple PMC carrier for use with the V5C SBC

-

Abaco VIPC8243 is an intelligent 6U VME carrier board

-

Abaco DCPMC Conduction-cooled or Rugged PMC Carrier

-

Abaco CP237 is a 6U CompactPCI Card

-

Abaco VME-3413 32-Channel Signal Conditioning Board

-

Abaco VME-3125 VME Analog I/O Input Boards

-

Alstom GE SPU232.2. 029.366.817 Single Processor Unit SPU2322

-

ALSTOM COP232.2 VME A32/D32, 029.232 446 controller unit

-

ICS TRIPLEX T8111C Trusted TMR Processor

-

VMIC VMIVME-7740 VME Single Board Compute 750

-

foxboro FBM232 Field Device System Integrator Module P0926GW

-

GE 04220HL21204A IPC Control Module

-

ABB 3BSE000860R1 SB510 Backup Power

-

ABB 0504994880 Controller unit

-

ABB PFSA140 3BSE006503R1 Industrial robot Supply Unit

-

ABB 5SHX1445H0002 3BHL000387P0101 POWER IGCT unit

-

ABB 128877-103 CABLE, SP1200 IR DET.

-

ABB CI853K01 and TP853 RS-232C Interface

-

ABB REM610 MOTOR PROTECTION RELAY REM610C11HCNR

-

ABB IGBT 5SDF0860H0003 5SDF1045H0002 unit

-

ABB TC512V1 3BSE018059R1 RS485 Twisted pair Modem

-

ABB DO880 S800HI 3BSE028602R1 Digital Output

-

ABB GDD360C 3BHE047217R0101 Advanced Automation Solution

-

ABB UCD240A101 3BHE022287R0101 controller unit

-

ABB AC800F Ethernet Module AM811F 3BDH000050R1

-

ABB AC800F Module AM801F 3BDH000040R1

-

ABB SD802F 3BDH000012R1 POWER UNIT

-

ABB operation panel PM820-2 3BSE010798R1 system module

-

ABB operation panel PM820-1 3BSE010797R1 system module

-

ABB CI857K01 3BSE018144R1 INSUM Ethernet Interface

-

ABB PM861/PM861AK01 and TP830 Processor Unit

-

ABB SA811F 3BDH000013R1 Power Supply 115/230 VAC

-

ABB 751010R0815 1VC1T0374A00R unit

-

5SGY35L4510 Robot high voltage board Brand ABB

-

ABB HVC-02B 3HNA024966-00103 Robot high voltage board Brand HVC02B

-

ABB SLMG99 UNIT

-

ABB 086406-002 PWA.SIOC. SMART I/O CALIP 086407-502

-

ABB UCD208A101 3BHE020018R0101 UNIT

-

ABB UAD154A 3BHE026866R0101 UNIT

-

ABB GCD207B101 3BHE024642R0101 controller card

-

ABB TB820V2 S800 Modulebus module 3BSE013208R1

-

ABB UDD406A 3BHE041465P201 Control unit

-

ABB PPD113B01-10-150000 3BHE023784R1023 unit CPU module

-

ABB 5SHY35L4512 3BHE014105R0001 5SXE08-0166 IGCT unit

-

ABB Backplane Uni Type3+housing FETD685A1156U01

-

ABB 07DC91C GJR5251400R0202 Digital input and output Unit

-

ABB UNS2881b-P,V1 3BHE009319R0001 UNS2881BPV1 Inspirational system

-

ABB UNS2880B-P,V2 3BHE014967R0002 UNS2880B-PV1 Inspirational system

-

ABB CI810B 3BSE020520R1 AF 100 Fieldbus Comm. Interface

-

ABB FM9925a-E HIEE451116R0001 Interface Module Card

-

Bently 2300/25 0002 Vibration Monitors

-

Bently 2300/20 0002 Vibration Monitors

-

ALSTOM VP327 020-23EU 75X-6025-29 Control mainboard VP32702

-

ABB NE802 3BSE080237R1 Industrial switch

-

ABB 3BSE080207R1 NE810 Industrial switch

-

MOTOROLA MVME2400 VME Processor Modules

-

ABB 3BHE021481R0001 intelligent current distr UNIT

-

MOTOROLA MVME2434 VME Processor Modules

-

METSO PDP606 CONTROLLER unit

-

WOODWARD PG-PL-29 Governor 8577-613

-

GE IS230TNRLH1B Combination module kit Mark VI

-

GE IS230TNAIH2C Combination module kit Mark VI

-

ABB 3ASC25H204 DAPU 100 Control board I/O

-

ABB 3BHE014070R0101 V PPC905AE101 CCB-2 COMPLETE

-

ABB PRC3BSE050198R1 PM866K01 Processor Unit

-

Kongsberg RAIV400 600370 Remote Analogue Input

-

ABB SPSED01 event sequence module

-

ABB HIEE300900R0001 PP C322 BE01 PSR-2 processor + fieldbus

-

ABB 3BHE003604R0102 UFC765AE102 circuit board

-

ABB ACU-01B 3HNA024871-001 Robot controller

-

ABB XVC770BE101 3BHE021083R0101 circuit board

-

ABB UAC383AE01 HIEE300890R0001 Module

-

ABB REF610C11LCNP FEEDER PROTECTION RELAY

-

ABB MT91 Operator Panel MT-91-ARC FP A

-

ABB XUD194 XUD194A 3BHC018137R0001 module base

-

ABB 5SHY4045L0001 3BHB018162 3BHE009681R0101 GVC750BE101

-

ABB G2000A5.7ST graphical operation panel (HMI)

-

ABB 3BHE017628R0002 PPD115A02 SG579989013

-

ABB Motor Protection and Control REM615 Product Guide

-

ABB PFTL101B 3BSE004185R1 2.0KN sensor

-

ABB PFCL201CE 50KN 3BSX802939-108 sensor

Add: High-tech Software Park, Xiamen City, Fujian Province

Mobile: +86-17750019513(WhatsApp)

Email: yy4291644@gmail.com

Website: https://www.abb-sis.com

-

WOODWARD 5448-890 SPM-D10 Series One Breaker Synchronizer

-

FOXBORO 43AP-FA42D/PB-AA 43AP Pneumatic Indicating Controllers

-

Stucke Elektronik SYMAP®G generator protection

-

Stucke Elektronik SYMAP®F feeder protection

-

Stucke Elektronik SYMAP®ECG engine control and generator protection

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)